A Comprehensive Review Of Automated Visual Inspection For Lyophilized Vials

Table of Contents

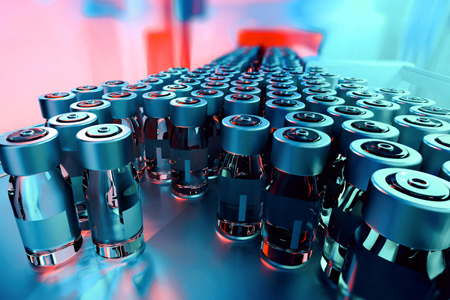

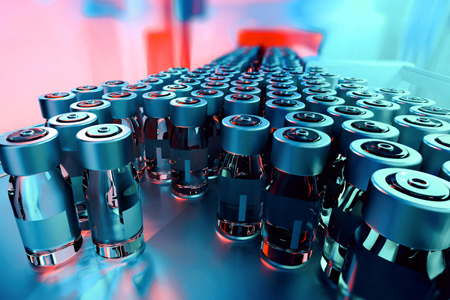

Manual inspection of lyophilized vials is time-consuming, subjective, and prone to human error, leading to inconsistencies and potentially overlooking critical defects. Automated visual inspection systems offer a robust solution, providing faster, more accurate, and consistent quality control. This review will delve into the various aspects of this technology, helping pharmaceutical manufacturers make informed decisions about upgrading their inspection processes.

Technologies Used in Automated Visual Inspection Systems for Lyophilized Vials

Automated visual inspection systems for lyophilized vials rely on sophisticated technologies to detect defects with high accuracy and speed. These systems typically incorporate several key components working in concert.

Image Acquisition Techniques

The process begins with acquiring high-quality images of each vial. Several techniques are employed:

- High-Resolution Cameras: These cameras capture detailed images of the vial's exterior, allowing for the detection of even minute defects. The resolution directly impacts the sensitivity of defect detection.

- Various Lighting Techniques: Different lighting configurations, such as bright-field, dark-field, and backlighting, are used to highlight different types of defects. For example, backlighting can effectively reveal cracks or particulate matter within the vial. Specialized lighting techniques like polarized light can also enhance the visibility of certain imperfections.

- Spectral Imaging: This advanced technique captures images across multiple wavelengths, allowing for the detection of defects that are invisible to the naked eye or under standard lighting. This is particularly useful for identifying subtle variations in the lyophilized cake's appearance.

Advantages and Disadvantages:

| Technique | Advantages | Disadvantages |

|---|---|---|

| High-Resolution Cameras | High detail, relatively low cost | Can be sensitive to lighting variations |

| Various Lighting Techniques | Enhanced visibility of specific defects | Requires careful optimization for different defect types |

| Spectral Imaging | Detection of defects invisible under standard lighting, enhanced sensitivity | High cost, complex data analysis |

Image Processing and Analysis Algorithms

Once images are acquired, sophisticated algorithms analyze them to identify defects. This often involves the use of Artificial Intelligence (AI) and Machine Learning (ML):

- AI and Machine Learning: These technologies enable the system to "learn" to identify defects by analyzing a large dataset of images with known defects. This allows for continuous improvement in accuracy and adaptability to different vial types and defect characteristics.

- Defect Identification Algorithms: Various algorithms are employed to identify specific defects:

- Crack Detection: Algorithms identify linear breaks or fissures in the vial's surface.

- Particulate Matter Detection: Algorithms detect foreign particles within the vial.

- Fill Level Variation Detection: Algorithms measure the height of the lyophilized cake and identify deviations from the expected level.

- Algorithm Training and Validation: Rigorous training and validation are crucial to ensure the algorithm's accuracy and reliability. This involves using a large, representative dataset of images to train the algorithm and then independently testing its performance on a separate dataset.

Common algorithms include:

- Deep Learning

- Convolutional Neural Networks (CNNs)

System Integration and Automation

Automated visual inspection systems are designed to integrate seamlessly into existing pharmaceutical production lines.

- Robotic Systems: Robotic arms handle and transport vials, feeding them into the inspection system and removing them afterward. This ensures efficient and consistent handling throughout the process.

- Increased Throughput: Automation significantly increases the throughput of the inspection process, allowing for the inspection of a much larger number of vials in a given time.

- Reduced Labor Costs: Automation reduces the need for manual labor, leading to significant cost savings in the long run.

Key Integration Considerations:

- Data Management: Secure storage and retrieval of inspection data.

- Regulatory Compliance: Meeting requirements such as 21 CFR Part 11.

- System Validation: Ensuring the system meets predefined performance specifications.

Benefits of Automated Visual Inspection for Lyophilized Vials

Implementing automated visual inspection offers numerous advantages:

Improved Accuracy and Consistency

Automated systems significantly reduce human error, leading to more consistent and reliable defect detection. Studies have shown that automated systems can achieve detection rates exceeding 99%, significantly higher than manual methods.

Increased Throughput and Efficiency

Automation dramatically speeds up the inspection process. A single automated system can inspect thousands of vials per hour, compared to the limited capacity of manual inspection. This translates to higher production capacity and faster time-to-market.

Reduced Labor Costs

The automation of the inspection process reduces the need for a large workforce dedicated to manual inspection, leading to substantial cost savings. These savings can offset the initial investment cost over time.

Enhanced Data Management and Traceability

Automated systems provide detailed data logging and reporting features. This improved data management ensures complete product traceability and facilitates compliance with regulatory requirements.

- Detailed data logs for each vial inspected.

- Real-time reporting and analytics dashboards.

- Integration with Enterprise Resource Planning (ERP) systems.

Challenges and Considerations in Implementing Automated Visual Inspection

While automated visual inspection offers significant advantages, several challenges must be considered:

Cost of Implementation

The initial investment for purchasing and implementing an automated visual inspection system can be substantial. However, this cost should be weighed against the long-term benefits of increased efficiency and reduced labor costs.

Validation and Qualification

Rigorous validation and qualification are essential to ensure the system meets regulatory requirements, including 21 CFR Part 11 compliance for electronic records and signatures.

Maintenance and Calibration

Automated systems require regular maintenance and calibration to ensure their accuracy and reliability over time. This adds to the overall operational cost.

System Integration Complexity

Integrating the system into existing production lines can be complex and may require significant modifications to the existing infrastructure. This integration process might involve downtime, posing potential production disruptions. Compatibility issues between different systems must be carefully addressed.

Conclusion

Automated Visual Inspection for Lyophilized Vials offers a significant upgrade over traditional manual methods. The enhanced accuracy, increased throughput, and reduced labor costs make it a compelling investment for pharmaceutical manufacturers. While initial costs and integration complexities exist, the long-term benefits far outweigh the challenges. The improved data management and traceability capabilities further enhance the value proposition.

Key Takeaways:

- Automated systems significantly improve accuracy and consistency in defect detection.

- Automation dramatically increases throughput and efficiency.

- Implementation leads to substantial cost savings in the long run.

- Improved data management ensures better traceability and regulatory compliance.

Invest in automated visual inspection for lyophilized vials to improve your production efficiency and ensure product quality. Learn more about the latest advancements in automated visual inspection solutions for lyophilized vials and take the next step towards a more efficient and reliable quality control process.

Featured Posts

-

The Surprising Ways Apple Supports Googles Ecosystem

May 11, 2025

The Surprising Ways Apple Supports Googles Ecosystem

May 11, 2025 -

Lily Collins And Charlie Mc Dowells Daughter Tove Family Photos

May 11, 2025

Lily Collins And Charlie Mc Dowells Daughter Tove Family Photos

May 11, 2025 -

Analyse Du Dechiffrage Comment L Euro Surmonte Les Tensions Actuelles

May 11, 2025

Analyse Du Dechiffrage Comment L Euro Surmonte Les Tensions Actuelles

May 11, 2025 -

Bundesliga 2023 24 Relegation Confirmed For Bochum And Holstein Kiel Leipzig Out Of Champions League

May 11, 2025

Bundesliga 2023 24 Relegation Confirmed For Bochum And Holstein Kiel Leipzig Out Of Champions League

May 11, 2025 -

Hanouna Sur M6 Un Animateur Star Reagit

May 11, 2025

Hanouna Sur M6 Un Animateur Star Reagit

May 11, 2025