AI-Powered Process Safety: A New Patent's Approach To Hazard Reduction

Table of Contents

Understanding the Limitations of Traditional Process Safety Methods

Traditional process safety relies heavily on human inspection, reactive measures, and rule-based systems. This approach suffers from several key limitations:

- High reliance on human error: Human fatigue, oversight, and misjudgment can lead to accidents.

- Difficulty in detecting subtle anomalies: Traditional methods often miss early warning signs of potential hazards, leading to delayed responses.

- Inefficient use of resources: Reactive measures are costly and often disrupt operations.

- Reactive rather than proactive approach: Traditional methods focus on responding to incidents rather than preventing them.

- Limited scalability to complex processes: Managing safety in large, complex industrial facilities using traditional methods is challenging and prone to errors. The sheer volume of data and interconnected systems requires a more sophisticated approach. This is where AI safety steps in to bridge this critical gap.

The Novel AI-Powered Approach Detailed in the New Patent

This new patent details a system that uses AI-powered process safety to proactively identify and mitigate potential hazards. The core technology leverages advanced machine learning algorithms, specifically deep learning, to analyze real-time data from various sensors deployed throughout an industrial facility. These sensors collect data on critical parameters such as:

- Real-time data analysis from various sensors: Temperature, pressure, flow rate, vibration, chemical composition, and other relevant parameters are continuously monitored.

- Machine learning algorithms for anomaly detection and predictive modeling: Sophisticated algorithms identify deviations from normal operating patterns, predicting potential failures or hazardous situations before they occur.

- Identification of subtle patterns indicative of impending hazards: The AI can detect subtle anomalies that might be missed by human operators, providing early warnings of potential problems.

- Integration with existing safety management systems (SMS): The AI seamlessly integrates with existing safety protocols, enhancing existing systems rather than replacing them.

- Automated alerts and recommendations for preventative actions: The system automatically alerts operators to potential hazards and suggests preventative actions, significantly reducing response times.

Specific Examples of Hazard Reduction

The applications of this AI-powered process safety system are extensive and can dramatically reduce various hazards:

- Predictive maintenance to prevent catastrophic equipment failures: By analyzing sensor data, the AI can predict equipment failures before they occur, allowing for timely maintenance and preventing costly downtime and potential accidents.

- Early detection of leaks or pressure surges: The system can detect even minor leaks or pressure fluctuations, enabling rapid intervention and preventing escalation to major incidents.

- Optimized emergency shutdown procedures: The AI can analyze various scenarios and optimize emergency shutdown procedures to minimize damage and ensure personnel safety.

- Improved operator training and decision support: The system provides valuable data and insights to enhance operator training and improve decision-making during critical situations.

- Reduced human intervention in hazardous areas: By automating monitoring and response, the system reduces the need for human intervention in hazardous environments, improving overall worker safety.

Benefits of Implementing AI-Powered Process Safety

Adopting this technology offers significant advantages across the board:

- Significant reduction in accidents and injuries: Proactive hazard detection and mitigation significantly reduce the likelihood of accidents and worker injuries.

- Improved operational efficiency and uptime: Preventative maintenance and reduced downtime contribute to improved operational efficiency.

- Cost savings through preventative maintenance and reduced downtime: The proactive nature of the system leads to significant cost savings in the long run.

- Enhanced regulatory compliance: Improved safety measures ensure better compliance with industry regulations and standards.

- Increased overall safety culture within the organization: The implementation of this technology fosters a proactive safety culture, promoting a safer work environment for everyone.

Future Implications and Further Research

The future of AI in process safety is bright, with exciting potential for further development and application:

- Integration with other emerging technologies (e.g., IoT, blockchain): Integrating with the Internet of Things (IoT) and blockchain technology can further enhance data security and system reliability.

- Development of more sophisticated AI algorithms for improved accuracy: Ongoing research focuses on developing even more accurate and robust AI algorithms.

- Expansion to a wider range of industries and processes: This technology has the potential to revolutionize safety across various sectors.

- Research on ethical considerations and responsible AI implementation in safety-critical systems: Ensuring responsible and ethical implementation of AI in safety-critical systems is paramount.

Conclusion

This new patent showcases the transformative potential of AI-powered process safety in drastically reducing hazards and improving industrial safety. By leveraging advanced analytics and predictive modeling, this technology offers a proactive, data-driven approach that surpasses traditional methods. This innovative use of machine learning and risk assessment signifies a significant leap forward in industrial safety management.

Call to Action: Learn more about this revolutionary approach to AI-powered process safety and how it can enhance your organization's safety protocols and minimize risks. Contact us today to explore how AI-powered hazard reduction can benefit your operations.

Featured Posts

-

Inmate Death Prompts Family Lawsuit Against San Diego County Sheriff

Apr 30, 2025

Inmate Death Prompts Family Lawsuit Against San Diego County Sheriff

Apr 30, 2025 -

Channing Tatums Girlfriend Inka Williams Leaves Sydney

Apr 30, 2025

Channing Tatums Girlfriend Inka Williams Leaves Sydney

Apr 30, 2025 -

Schneider Electric Surpasses 2024 Sustainability Goals A Milestone Achieved

Apr 30, 2025

Schneider Electric Surpasses 2024 Sustainability Goals A Milestone Achieved

Apr 30, 2025 -

The March Movement Tracking Changes In Dance Directors And Performers

Apr 30, 2025

The March Movement Tracking Changes In Dance Directors And Performers

Apr 30, 2025 -

Jay Z Blue Ivy And Rumi Carter At The Super Bowl Family Photos

Apr 30, 2025

Jay Z Blue Ivy And Rumi Carter At The Super Bowl Family Photos

Apr 30, 2025

Latest Posts

-

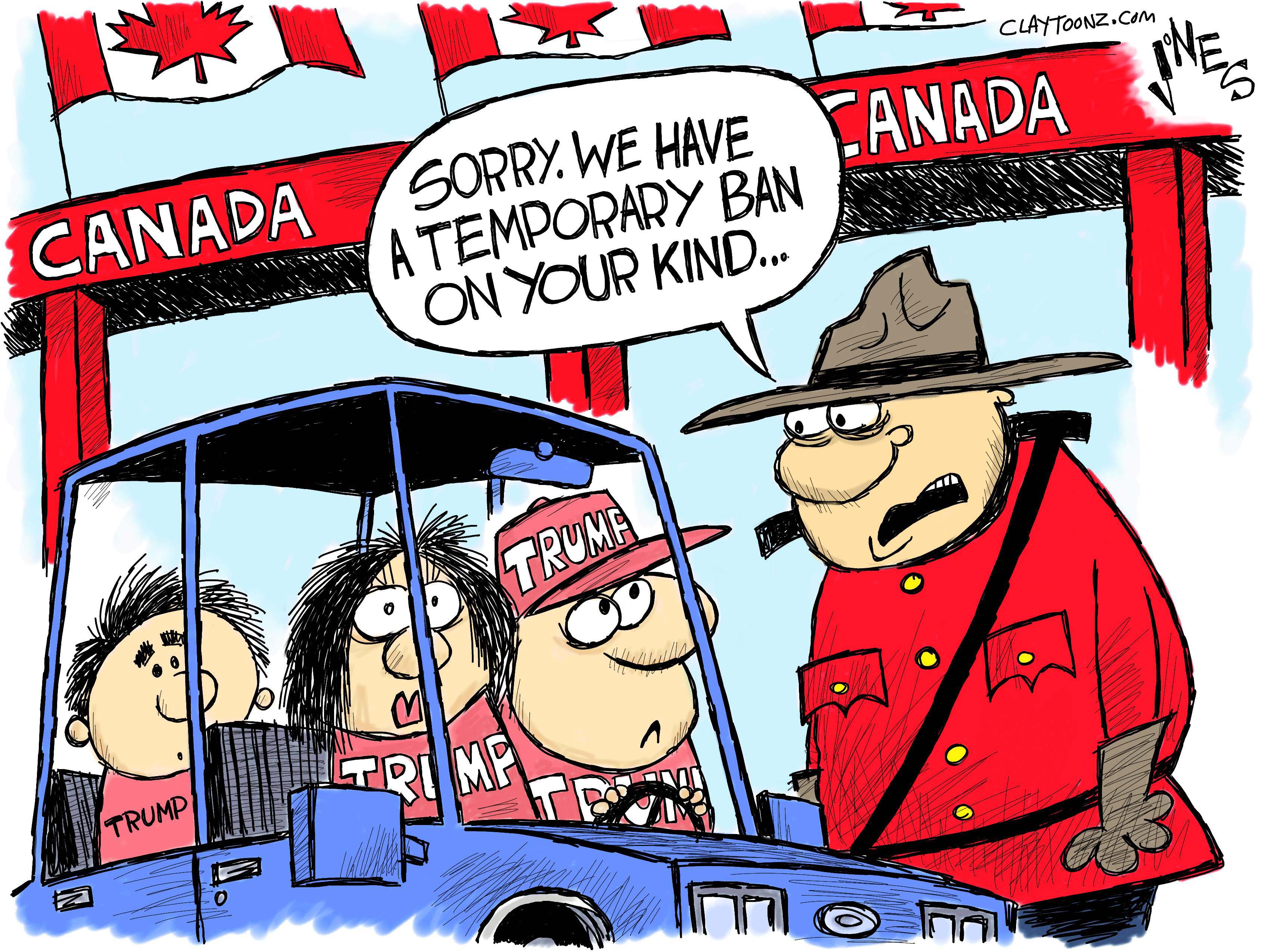

Trumps Election Claim Days Before Canadian Vote Us Importance Questioned

Apr 30, 2025

Trumps Election Claim Days Before Canadian Vote Us Importance Questioned

Apr 30, 2025 -

Disneys Abc News Layoffs 200 Employees Affected 538 Cuts

Apr 30, 2025

Disneys Abc News Layoffs 200 Employees Affected 538 Cuts

Apr 30, 2025 -

Days Before Canadian Election Trumps Bold Claim About Us Canada Relations

Apr 30, 2025

Days Before Canadian Election Trumps Bold Claim About Us Canada Relations

Apr 30, 2025 -

Disney Cuts 200 Abc News Jobs Impacting 538

Apr 30, 2025

Disney Cuts 200 Abc News Jobs Impacting 538

Apr 30, 2025 -

Trumps Election Interference Claim Days Before Canadian Vote He Asserts Us Dominance

Apr 30, 2025

Trumps Election Interference Claim Days Before Canadian Vote He Asserts Us Dominance

Apr 30, 2025