Analyzing The Big Rig ROCK Report: 3.12 | 97.1 Double Q Metrics

Table of Contents

Understanding the Big Rig ROCK Report Structure

The Big Rig ROCK Report, assuming it's a Rockwell Automation-based system report, is likely designed to provide a comprehensive overview of your manufacturing processes. Understanding its structure and the specific metrics within it is crucial for effective data analysis.

Defining the 3.12 Metric

The 3.12 metric within the Big Rig ROCK Report likely represents a key performance indicator related to production throughput or cycle time. While the exact definition depends on your specific system configuration, it could represent units produced per hour, total production time, or overall equipment effectiveness (OEE) within a specific timeframe.

- Definition (Example): 3.12 might represent the number of parts produced per hour on a specific machine.

- Formula (Example): 3.12 = Total Parts Produced / Total Production Hours

- Practical Example: If a machine produces 312 parts in 1 hour, the 3.12 metric would equal 312.

- Importance: A higher 3.12 value indicates improved productivity and efficiency. Tracking this metric helps identify bottlenecks and areas for process optimization.

Deciphering the 97.1 Double Q Metric

The 97.1 Double Q metric likely relates to quality control and defect rates. The "Double Q" likely signifies a double-checking or verification step within your quality control process.

- Definition: This metric probably represents the defect rate or the percentage of defective products produced within a specified timeframe. A lower value signifies higher quality.

- Double Q Significance: The "Double Q" terminology implies a robust quality control process with redundant checks to minimize errors. This might involve two independent quality control inspections.

- Implications of Values: A high 97.1 value indicates significant quality issues and the need for immediate attention, while a low value shows robust quality control.

Key Components of the Report

Besides 3.12 and 97.1 Double Q, the Big Rig ROCK Report likely includes other crucial data points:

- Timestamps: Precise timestamps are crucial for tracking trends and identifying patterns in performance.

- Machine IDs: This allows you to isolate performance issues to specific machines.

- Operator IDs: Helps to analyze the impact of different operators on production and quality.

- Material IDs: Tracks the performance associated with different raw materials used.

- Environmental Data (Temperature, Humidity): This can be crucial for understanding external factors impacting the process.

These additional data points provide a holistic view and assist in the accurate interpretation of 3.12 and 97.1 Double Q metrics.

Analyzing Trends and Identifying Areas for Improvement

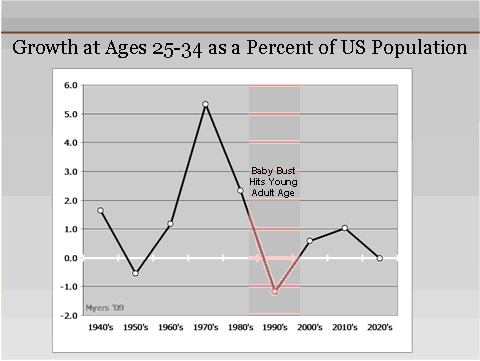

Raw data is only useful if you can interpret it to identify issues and opportunities for improvement. Data visualization and correlation analysis play crucial roles.

Visualizing Data for Better Insights

Employing visual tools like line graphs, bar charts, and scatter plots helps illuminate trends in your 3.12 and 97.1 Double Q metrics.

- Line Graphs: Ideal for showing trends over time, spotting anomalies, and identifying seasonal or cyclical patterns.

- Bar Charts: Useful for comparing metrics across different machines, operators, or time periods.

- Scatter Plots: Help identify correlations between different variables (e.g., 3.12 vs. 97.1, production volume vs. defect rate).

Correlation Analysis

Analyzing the relationship between 3.12 and 97.1 with other data points in the report can unveil hidden correlations.

- Example: A negative correlation between 3.12 (production rate) and 97.1 (defect rate) might suggest that rushing production leads to higher defect rates.

- Example: A positive correlation between a specific machine's downtime and the 97.1 metric might suggest that the machine needs maintenance.

Identifying these correlations points to root causes of inefficiencies or quality problems.

Benchmarking and Best Practices

Comparing your 3.12 and 97.1 Double Q metrics against industry benchmarks helps assess your performance relative to competitors.

- Identifying Benchmarks: Look for industry reports, best practice guides, or data from similar manufacturing facilities.

- Improvement Strategies: Based on the comparison, define specific strategies to improve your metrics – this could involve process re-engineering, machine upgrades, or employee training programs.

Implementing Strategies for Optimization Based on Big Rig ROCK Report Data

Data-driven optimization involves using insights from your analysis to implement practical changes.

Addressing Low 3.12 Metrics

If your 3.12 metric (production rate) is low, consider the following:

- Process Optimization: Streamline workflows, eliminate bottlenecks, and optimize production processes.

- Equipment Upgrades: Invest in modern, more efficient machinery to increase production capacity.

- Employee Training: Invest in training programs to improve operator skills and efficiency. This can significantly impact production rates.

Each strategy should be carefully evaluated for its potential return on investment (ROI).

Reducing High 97.1 Double Q Metrics

High 97.1 Double Q metrics (high defect rates) signal the need for immediate action:

- Improved Quality Control Procedures: Implement stricter quality checks at each stage of the process, possibly incorporating additional layers of verification (consistent with the "Double Q" concept).

- Preventative Maintenance: Regularly maintain equipment to prevent malfunctions that lead to defective products.

- Enhanced Operator Training: Train operators on proper operating procedures and quality control checks.

Continuous improvement is crucial to consistently reduce the 97.1 metric.

Utilizing Data for Predictive Maintenance

Analyzing historical data from the Big Rig ROCK Report can be used for predictive maintenance.

- Predictive Maintenance Benefits: Prevents costly downtime and reduces the risk of major equipment failures.

- Data Analytics Role: By identifying patterns and trends in machine performance data, you can anticipate potential failures and schedule maintenance proactively.

Conclusion

Mastering the intricacies of your Big Rig ROCK Report and its key metrics like 3.12 and 97.1 Double Q is crucial for maximizing operational efficiency. Thoroughly analyzing this data allows for the identification of trends, correlations, and areas for improvement within your manufacturing processes. By implementing data-driven strategies, you can significantly enhance both productivity and product quality. Start analyzing your data today and unlock significant improvements in your manufacturing processes! Explore Rockwell Automation solutions or similar industrial automation systems and data analysis techniques to further refine your approach and unlock the full potential of your Big Rig ROCK Report (or equivalent) data.

Featured Posts

-

Rain Hit Match Najmul Hossain Shantos Match Winning Contribution For Bangladesh

May 23, 2025

Rain Hit Match Najmul Hossain Shantos Match Winning Contribution For Bangladesh

May 23, 2025 -

Egan Bernals Recovery From A Critical Cycling Accident Insights From Medical Research

May 23, 2025

Egan Bernals Recovery From A Critical Cycling Accident Insights From Medical Research

May 23, 2025 -

The Karate Kid Part Iii Comparing It To The Previous Films

May 23, 2025

The Karate Kid Part Iii Comparing It To The Previous Films

May 23, 2025 -

Cat Deeleys Denim Dress Recreate Her This Morning Cowboy Style

May 23, 2025

Cat Deeleys Denim Dress Recreate Her This Morning Cowboy Style

May 23, 2025 -

Lewis Hamilton And Mc Laren Unresolved Issues And Recent Admissions

May 23, 2025

Lewis Hamilton And Mc Laren Unresolved Issues And Recent Admissions

May 23, 2025

Latest Posts

-

Netflixs May 2025 Lineup Movies And Tv Shows

May 23, 2025

Netflixs May 2025 Lineup Movies And Tv Shows

May 23, 2025 -

Formula 1 Wolffs Upbeat Assessment Following Successful Start

May 23, 2025

Formula 1 Wolffs Upbeat Assessment Following Successful Start

May 23, 2025 -

Swiss Alps Emergency Livestock Removal Due To Landslide Danger

May 23, 2025

Swiss Alps Emergency Livestock Removal Due To Landslide Danger

May 23, 2025 -

2025 Ncaa Tournament Bishop Englands Contribution To Louisvilles Team

May 23, 2025

2025 Ncaa Tournament Bishop Englands Contribution To Louisvilles Team

May 23, 2025 -

Whats New On Netflix In May 2025

May 23, 2025

Whats New On Netflix In May 2025

May 23, 2025