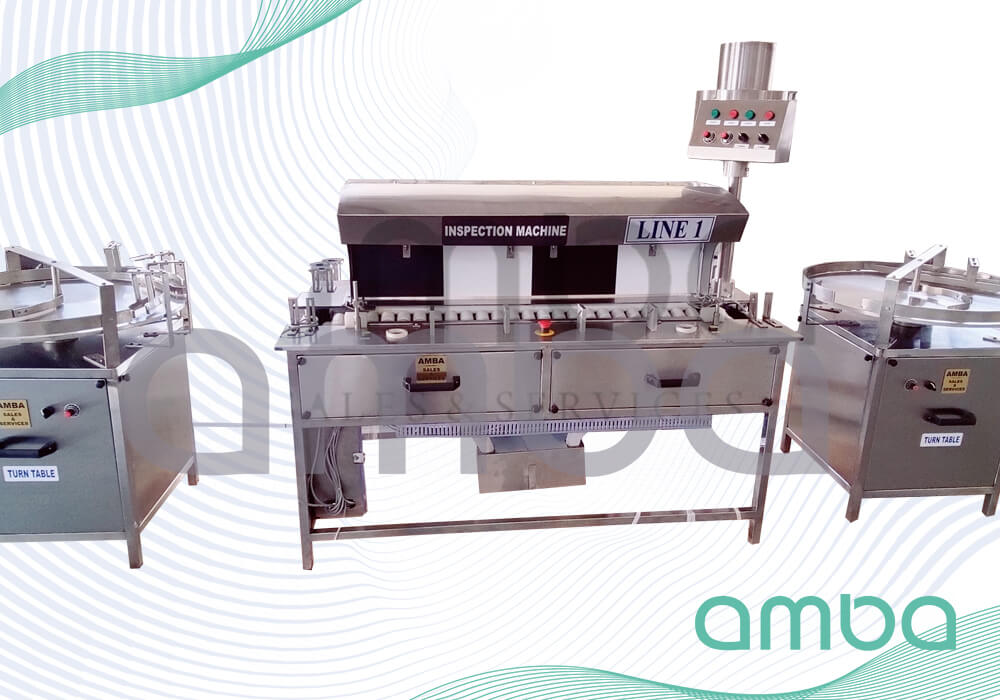

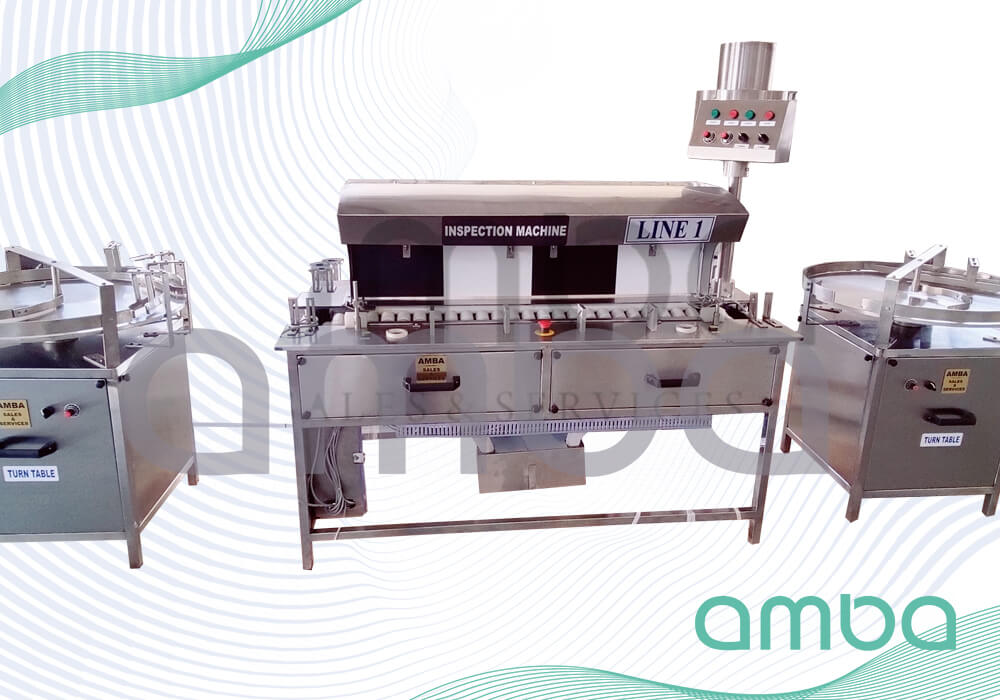

Automated Visual Inspection Of Lyophilized Vials: Overcoming Key Challenges

Table of Contents

Challenges of Manual Visual Inspection of Lyophilized Vials

Manual visual inspection of lyophilized vials presents several significant challenges that impact both product quality and production efficiency. These challenges highlight the need for advanced automated solutions.

Subjectivity and Variability

Human inspectors can have varying interpretations of defects, leading to inconsistencies and potential product recalls. This subjectivity significantly impacts the reliability of the inspection process.

- Differences in lighting: Inconsistencies in lighting conditions can affect an inspector's ability to detect subtle defects.

- Inspector fatigue: Fatigue and reduced concentration can lead to missed defects, especially during long inspection shifts.

- Lack of standardized criteria: Without clear and consistently applied criteria, different inspectors may classify the same defect differently.

This subjectivity can lead to false positives (rejecting good vials) or false negatives (accepting defective vials), impacting both production efficiency and, critically, product safety. Maintaining consistent quality control under manual inspection is extremely difficult.

Bottlenecks in Production

Manual inspection is significantly slower than automated systems, creating a significant bottleneck in the production pipeline. This delay impacts overall production capacity and can lead to significant delays.

- Reduced throughput: The speed of manual inspection limits the number of vials that can be processed per unit of time.

- Increased lead times: Bottlenecks in inspection lead to increased lead times for getting products to market.

- Potential delays in bringing life-saving medications to market: For time-sensitive medications, delays can have serious consequences.

This bottleneck is particularly problematic in high-volume manufacturing environments where speed and efficiency are paramount. The inability to scale manual inspection to meet increasing demand makes it unsustainable for many pharmaceutical manufacturers.

High Labor Costs and Difficulty in Maintaining a Skilled Workforce

The need for highly trained personnel increases labor costs and creates challenges in retaining skilled inspectors. This issue impacts both budget and operational stability.

- Training costs: Training inspectors to accurately identify a wide range of defects requires significant investment.

- High turnover rates: The often repetitive and demanding nature of the work can lead to high employee turnover.

- Difficulty in finding qualified personnel: Finding and retaining skilled personnel with the necessary expertise can be challenging.

Automation can mitigate this by reducing reliance on highly skilled manual labor and offering a more consistent and reliable inspection process.

Advantages of Automated Visual Inspection Systems for Lyophilized Vials

Automated visual inspection systems offer numerous advantages over manual methods, addressing the key challenges outlined above. These systems provide a more efficient, accurate, and cost-effective solution.

Enhanced Accuracy and Consistency

Automated systems provide objective and consistent evaluation, minimizing human error and ensuring consistent quality control. Advanced image processing algorithms are key to this improvement.

- Improved defect detection rates: Automated systems can detect subtle defects often missed by the human eye.

- Reduced false positives and negatives: Objective analysis minimizes errors in classification.

- Enhanced product quality: Consistent and accurate inspection leads to higher overall product quality.

Advanced image processing algorithms analyze every vial, identifying subtle defects such as cracks, particulate matter, and inconsistencies in fill levels with far greater precision than manual inspection.

Increased Throughput and Efficiency

Automated systems significantly increase the speed of inspection, boosting production capacity. This efficiency translates directly to cost savings and faster time-to-market.

- Faster processing times: Automated systems can inspect many more vials per hour compared to manual inspection.

- Increased production volume: Higher throughput allows for increased production volume without requiring a corresponding increase in labor.

- Improved overall efficiency: Streamlined inspection processes improve overall production efficiency.

This leads to lower production costs and faster time-to-market, giving pharmaceutical companies a competitive edge.

Reduced Labor Costs and Improved ROI

Automation reduces the need for manual labor, leading to significant cost savings in the long run. The initial investment is quickly offset by long-term benefits.

- Lower labor costs: Reduced reliance on manual labor translates to significant savings in wages and benefits.

- Reduced training expenses: Automated systems require less training and ongoing supervision.

- Improved return on investment (ROI): The increased efficiency and cost savings quickly outweigh the initial investment.

The initial investment in automated systems is quickly offset by increased efficiency and reduced labor costs, leading to a strong return on investment.

Data Management and Traceability

Automated systems provide detailed records of inspection results, facilitating data analysis and traceability. This improves compliance and allows for better process optimization.

- Real-time data analysis: Automated systems provide immediate feedback on inspection results.

- Improved process control: Data analysis helps identify trends and improve process control.

- Enhanced compliance with regulatory requirements: Detailed records facilitate compliance audits.

This data allows for better process optimization and faster response to any quality issues, further enhancing overall efficiency and product quality.

Choosing the Right Automated Visual Inspection System

Selecting the right automated visual inspection system requires careful consideration of several factors to ensure optimal performance and return on investment.

Considerations for Selection

Several key factors must be considered when choosing an automated visual inspection system for lyophilized vials.

- Vial size and shape: The system must be compatible with the specific size and shape of your vials.

- Throughput requirements: The system must be able to handle your desired production volume.

- Types of defects to be detected: The system's capabilities must match the types of defects you need to identify.

- Budget constraints: Consider the initial investment cost, maintenance costs, and long-term operational expenses.

- System capabilities: Evaluate the system's speed, accuracy, and ability to integrate with existing equipment.

- Integration with existing equipment: Seamless integration with your existing production line is essential.

- Maintenance requirements: Consider the ongoing maintenance and service requirements of the system.

Consult with experts to determine the best system for your specific needs and ensure a smooth integration into your existing workflow.

Conclusion

Automated visual inspection of lyophilized vials is crucial for ensuring product quality, maintaining regulatory compliance, and maximizing production efficiency. While manual inspection faces significant limitations, automated systems offer a superior solution by improving accuracy, increasing throughput, reducing costs, and enhancing data management. Investing in the right automated visual inspection system is a strategic move towards ensuring the highest quality standards for your lyophilized products. Consider exploring the available automated visual inspection systems to optimize your lyophilization process and improve overall production outcomes. Don't compromise on quality; embrace the benefits of automated visual inspection of lyophilized vials today.

Featured Posts

-

Presidente De Uruguay Regala Tres Toros A Xi Jinping Su Viaje A China

May 11, 2025

Presidente De Uruguay Regala Tres Toros A Xi Jinping Su Viaje A China

May 11, 2025 -

Thomas Muellers Framtid Mls Alternativet Vaexer

May 11, 2025

Thomas Muellers Framtid Mls Alternativet Vaexer

May 11, 2025 -

Semana De Turismo En Uruguay Un Analisis De Su Significado Historico Y Social

May 11, 2025

Semana De Turismo En Uruguay Un Analisis De Su Significado Historico Y Social

May 11, 2025 -

Mueller Confirme Son Depart Du Bayern Munich Apres 25 Saisons

May 11, 2025

Mueller Confirme Son Depart Du Bayern Munich Apres 25 Saisons

May 11, 2025 -

How Much Is Adam Sandler Worth A Look At The Comedians Impressive Fortune

May 11, 2025

How Much Is Adam Sandler Worth A Look At The Comedians Impressive Fortune

May 11, 2025