Electric Vehicle Battery Manufacturing: A Case Study Addendum On BYD's Success

Table of Contents

BYD's Vertical Integration Strategy

A key differentiator for BYD is its vertically integrated approach, controlling the entire battery supply chain from raw material sourcing to cell production and pack assembly. This strategy minimizes reliance on external suppliers, offering significant advantages in terms of cost control, quality assurance, and speed of innovation within the EV battery industry.

Raw Material Sourcing & Control

BYD secures access to crucial raw materials, minimizing supply chain vulnerabilities and ensuring consistent battery production. This proactive approach is a cornerstone of their success in lithium-ion battery manufacturing.

- Investments in mines and partnerships with suppliers: BYD has invested in securing direct access to lithium, cobalt, nickel, and manganese, reducing dependence on fluctuating market prices and potential shortages. This secures their position within the EV battery supply chain.

- Development of proprietary battery chemistries: BYD's research and development efforts focus on reducing reliance on specific, potentially volatile materials, like cobalt, through the development of alternative battery chemistries. This enhances the sustainability and cost-effectiveness of their EV battery production.

- Focus on sustainable and ethically sourced materials: BYD emphasizes environmentally responsible sourcing, enhancing its brand reputation and appealing to environmentally conscious consumers. This commitment to ethical sourcing is increasingly important in the EV battery market.

In-House Battery Cell & Pack Manufacturing

BYD's complete control over the manufacturing process allows for optimization at every stage, resulting in higher efficiency, lower costs, and faster innovation cycles in EV battery production.

- Massive-scale battery factories with advanced automation technologies: BYD operates large-scale, highly automated factories, enabling high-volume production of battery cells and packs. This allows them to meet the growing demand for EV batteries.

- Continuous improvement and R&D focused on improving battery energy density, lifespan, and safety: BYD consistently invests in R&D to improve battery performance, extending EV range and enhancing overall vehicle safety. This ongoing commitment to innovation is crucial for maintaining a competitive edge in the dynamic EV battery market.

- Flexibility to adapt to evolving market demands and emerging battery technologies: BYD's vertical integration allows for rapid adaptation to changing market demands and the integration of new battery technologies. This adaptability is key to remaining at the forefront of the EV battery industry.

Blade Battery Technology and Innovation

BYD's Blade Battery technology is a significant leap forward, offering higher energy density, improved safety, and space optimization compared to traditional cylindrical or prismatic cells. This innovative technology has significantly impacted the landscape of EV battery production.

Enhanced Energy Density

The Blade Battery's unique design allows for increased energy storage in the same volume, leading to extended EV range. This is a crucial advantage in the competitive EV market.

- Superior energy density compared to traditional lithium-ion battery packs: Blade Batteries offer a higher energy density per unit volume, translating to longer driving ranges for EVs.

- Increased range for EVs without compromising vehicle design: The enhanced energy density allows for increased range without sacrificing interior space or vehicle aesthetics.

Improved Safety Features

The Blade Battery's structural integration reduces the risk of thermal runaway and improves overall vehicle safety. This is a critical aspect of consumer confidence in EVs.

- Superior thermal stability compared to conventional battery designs: The design minimizes the risk of thermal events, enhancing overall battery safety.

- Reduced risk of fire or explosion: The improved thermal stability significantly reduces the risk of fire or explosion, addressing a major concern associated with EV batteries.

Space Optimization

The flat, blade-like form factor maximizes space utilization within the vehicle chassis, enhancing design flexibility. This innovative design offers significant advantages for vehicle manufacturers.

- Optimized packaging leading to larger passenger and cargo space: The efficient design allows for more interior space compared to traditional battery packs.

- Improved vehicle aerodynamics due to optimized battery placement: The Blade Battery's form factor can contribute to improved vehicle aerodynamics, increasing efficiency.

Global Expansion and Market Leadership

BYD's success isn't limited to its technological advancements; it's also driven by its strategic global expansion and partnerships. This global reach solidifies BYD's position as a leader in EV battery manufacturing.

International Market Penetration

BYD is aggressively expanding its market reach beyond China, establishing manufacturing facilities and partnerships globally. This international presence strengthens their position in the EV battery market.

- Growing presence in Europe, North America, and other key markets: BYD is actively expanding its manufacturing and distribution network globally.

- Strategic alliances with automotive manufacturers and energy companies: Partnerships with key players in the automotive and energy sectors further strengthen their market position.

Strong Brand Recognition and Reputation

BYD's consistent innovation and commitment to quality have fostered a strong brand image and customer trust. This positive brand perception enhances their market competitiveness.

- Positive media coverage and increasing consumer awareness: BYD's successes have generated positive media attention, raising consumer awareness of their products and brand.

- Competitive pricing and attractive warranties: BYD offers competitive pricing and warranties, making its products attractive to consumers.

Conclusion

BYD's success in electric vehicle battery manufacturing serves as a compelling case study, showcasing the importance of vertical integration, technological innovation, and strategic global expansion. Their Blade Battery technology represents a significant advancement, setting a new benchmark for the industry. The company’s comprehensive approach, from raw material sourcing to market penetration within the EV battery supply chain, highlights a blueprint for success in the rapidly growing electric vehicle battery market. If you are interested in learning more about innovative approaches to electric vehicle battery manufacturing, further research into BYD's strategies and the broader electric vehicle battery landscape is highly recommended. Understanding the intricacies of electric vehicle battery manufacturing is crucial for navigating this transformative sector.

Featured Posts

-

India And Myanmar Bond Over Delicious Food Festival

May 13, 2025

India And Myanmar Bond Over Delicious Food Festival

May 13, 2025 -

The Da Vinci Code History Symbolism And Controversy

May 13, 2025

The Da Vinci Code History Symbolism And Controversy

May 13, 2025 -

Evreyskaya Avtonomnaya Oblast I Programma Gazifikatsii Ot Gazproma

May 13, 2025

Evreyskaya Avtonomnaya Oblast I Programma Gazifikatsii Ot Gazproma

May 13, 2025 -

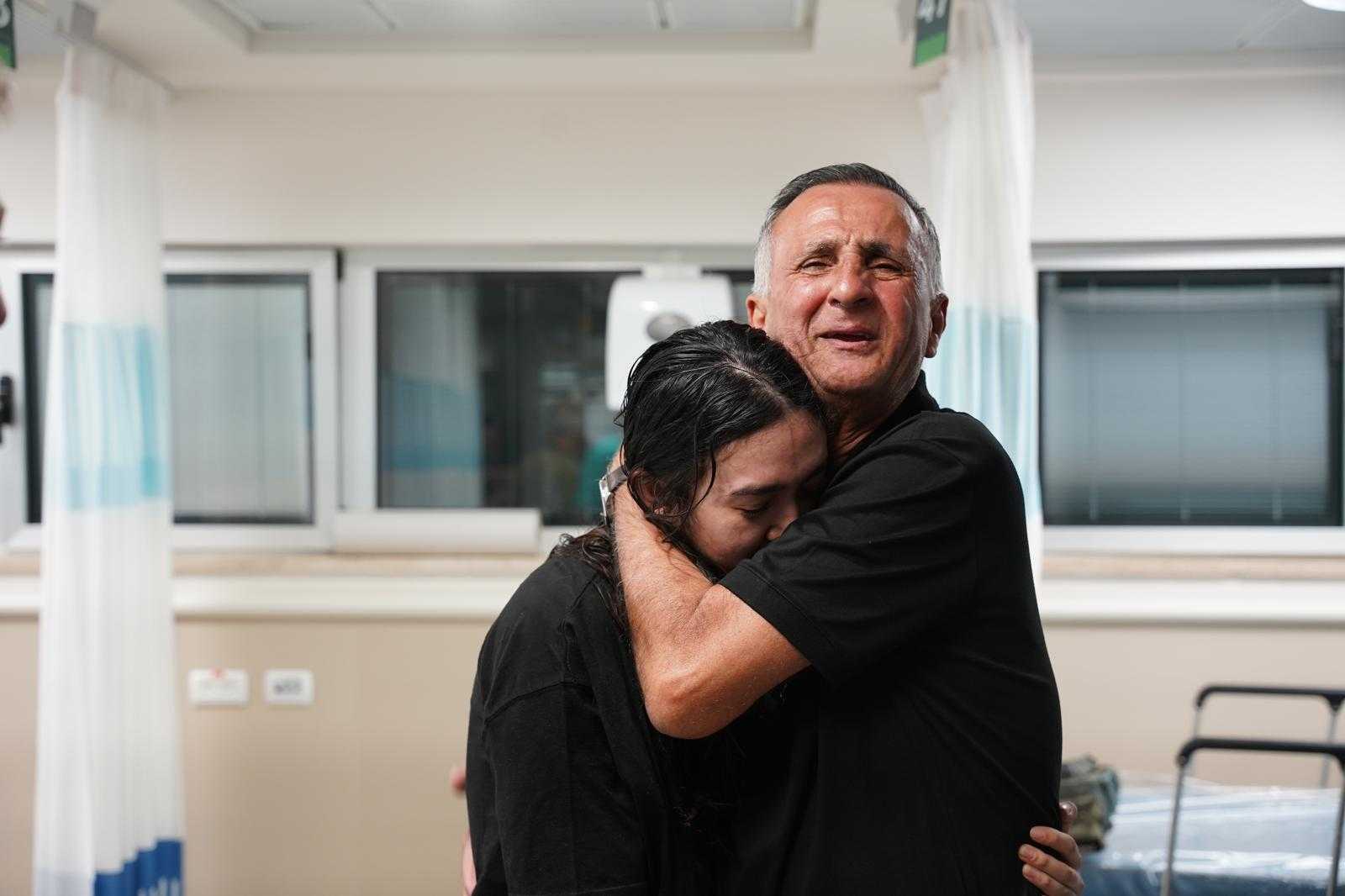

Gaza Hostage Crisis A Prolonged Struggle For Families

May 13, 2025

Gaza Hostage Crisis A Prolonged Struggle For Families

May 13, 2025 -

Ali Larter Opens Up About Her Lasting Relationship With Billy Bob Thornton

May 13, 2025

Ali Larter Opens Up About Her Lasting Relationship With Billy Bob Thornton

May 13, 2025