Exclusive Report: Ford's EV Pullback And The Nissan Battery Plant Collaboration

Table of Contents

Ford's EV Production Slowdown: Reasons and Analysis

Ford's decision to adjust its EV production targets hasn't come as a complete surprise, given the evolving dynamics of the electric vehicle market. Several factors contribute to this slowdown.

Decreased Demand and Market Challenges

The EV market, while experiencing significant growth, is not immune to economic fluctuations and evolving consumer preferences. Several challenges are impacting Ford's sales projections:

- Increased Competition: The EV market is becoming increasingly crowded, with established automakers and new entrants vying for market share. This intensified competition puts pressure on pricing and necessitates strategic adjustments.

- Rising Raw Material Costs: The costs of raw materials crucial for EV battery production, such as lithium and cobalt, have skyrocketed, impacting the overall cost of manufacturing and potentially affecting consumer affordability.

- Economic Uncertainty: Global economic instability and inflation are influencing consumer spending habits, leading to some hesitation in purchasing high-ticket items like electric vehicles.

- Consumer Hesitancy: Range anxiety, charging infrastructure limitations, and the overall perceived higher cost of EVs compared to gasoline-powered vehicles continue to be hurdles to wider adoption.

These factors have undoubtedly influenced Ford's production decisions. The impact is evident in areas like slower-than-expected sales of the Ford Mustang Mach-E and adjustments to the F-150 Lightning production schedule. The company is grappling with EV market saturation concerns and the need to recalibrate its production strategy to align with actual market demand. Addressing battery supply chain issues is also critical to future success.

Production Bottlenecks and Supply Chain Issues

Beyond market demand, Ford faces significant challenges in securing the components needed for EV production. These bottlenecks are impacting production timelines and overall strategy:

- Battery Cell Shortages: The global demand for lithium-ion battery cells far outstrips current production capacity, leading to shortages that directly impact Ford's ability to meet its production targets.

- Semiconductor Chip Scarcity: The ongoing semiconductor chip shortage continues to disrupt the automotive industry, affecting the production of various vehicle components, including EVs.

- Logistical Problems: Global supply chain disruptions, including port congestion and transportation delays, further complicate the procurement of necessary parts for EV manufacturing.

The impact of these bottlenecks is significant. Ford's ambitious EV production targets have been revised, reflecting the reality of navigating a complex and sometimes unpredictable supply chain. Addressing these challenges requires strategic partnerships and investment in securing reliable sources of raw materials and components. The company needs to optimize its lithium-ion battery production processes and integrate more resilient strategies into its supply chain.

The Nissan Battery Plant Collaboration: A Strategic Partnership

Ford's partnership with Nissan for battery production represents a pivotal strategic move aimed at addressing some of the challenges mentioned above.

Details of the Joint Venture

This joint venture signifies a major step towards securing a reliable supply of battery cells for both companies. Key details are still emerging, but the partnership is expected to:

- Shared Ownership: Involve a shared ownership structure between Ford and Nissan, combining their resources and expertise.

- Significant Production Capacity: Target a substantial increase in battery cell production capacity, addressing the current global shortage.

- Diverse Battery Cell Types: Produce a range of battery cells to cater to the diverse needs of both companies' EV models.

- Strategic Plant Locations: Establish battery plants in strategically chosen locations to optimize logistics and reduce transportation costs.

This collaboration allows Ford and Nissan to leverage each other's strengths and share the financial burden of building and operating large-scale battery production facilities. This approach mitigates individual risks and accelerates the development of sustainable energy solutions. The joint venture addresses the need for gigafactory-scale production, aiming to significantly boost the supply of battery cells and reduce costs.

Long-Term Implications for Both Companies

The long-term implications of this partnership are significant for both Ford and Nissan:

- Increased Market Share: Access to a reliable supply of battery cells will enable both companies to increase their EV production and compete more effectively in the growing EV market.

- Cost Reductions: Shared investment and economies of scale will lead to lower production costs, enhancing competitiveness and profitability.

- Technological Advancements: Collaboration will foster innovation and accelerate the development of advanced battery technologies.

- Enhanced Brand Image: The partnership demonstrates a commitment to sustainable transportation and enhances both companies' reputations as leaders in the EV sector.

This collaborative approach is reshaping the competitive landscape, giving both Ford and Nissan a distinct competitive advantage in the race for market leadership. The partnership contributes to broader efforts towards the electrification of transportation and sustainable energy solutions.

Conclusion

Ford's strategic adjustments to its EV production, driven by market challenges and supply chain issues, highlight the complexities of navigating the rapidly evolving EV market. The "Ford EV pullback," however, shouldn't be viewed solely as a setback but rather as a tactical repositioning. The strategic partnership with Nissan for battery production is a crucial element of this repositioning, offering a path to secure a reliable supply of high-quality battery cells and ultimately boost market competitiveness. This collaboration is a significant development with substantial long-term implications for both companies and the broader EV industry. Stay tuned for further updates on Ford's EV strategy and the evolution of its collaboration with Nissan. The future of electric vehicles hinges on partnerships like this, and understanding this dynamic relationship is key to understanding the future of Ford's future in EVs and Nissan-Ford battery technology. Keep abreast of EV industry news for continued insight into this evolving landscape.

Featured Posts

-

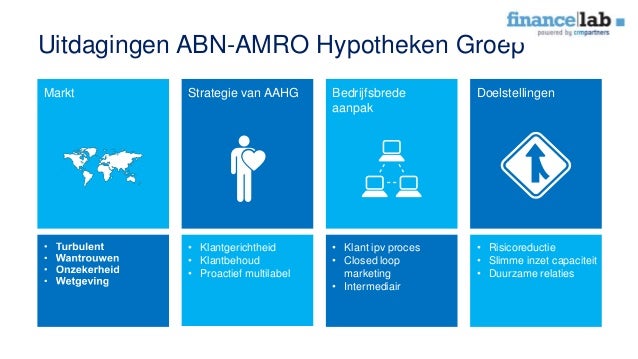

Karin Polman Nieuwe Directeur Hypotheken Bij Abn Amro Florius En Moneyou

May 22, 2025

Karin Polman Nieuwe Directeur Hypotheken Bij Abn Amro Florius En Moneyou

May 22, 2025 -

Blake Lively Separating Fact From Fiction In Recent Reports

May 22, 2025

Blake Lively Separating Fact From Fiction In Recent Reports

May 22, 2025 -

The Goldbergs Character Profiles And Relationships

May 22, 2025

The Goldbergs Character Profiles And Relationships

May 22, 2025 -

Tuerkiye Nato Da Yeni Bir Doenem Baslatiyor Zirvedeki Etkisi

May 22, 2025

Tuerkiye Nato Da Yeni Bir Doenem Baslatiyor Zirvedeki Etkisi

May 22, 2025 -

New Peppa Pig Theme Park Your Texas Family Vacation Destination

May 22, 2025

New Peppa Pig Theme Park Your Texas Family Vacation Destination

May 22, 2025

Latest Posts

-

Falling Gas Prices In Illinois A Look At The National Picture

May 22, 2025

Falling Gas Prices In Illinois A Look At The National Picture

May 22, 2025 -

Illinois Gas Prices Continue To Fall Nationwide Decrease Impacts State

May 22, 2025

Illinois Gas Prices Continue To Fall Nationwide Decrease Impacts State

May 22, 2025 -

Illinois Gas Prices Drop Following National Trend

May 22, 2025

Illinois Gas Prices Drop Following National Trend

May 22, 2025 -

Rising Gas Prices In Philadelphia Current Average And Future Outlook

May 22, 2025

Rising Gas Prices In Philadelphia Current Average And Future Outlook

May 22, 2025 -

Major Route 581 Traffic Disruption Due To Box Truck Accident

May 22, 2025

Major Route 581 Traffic Disruption Due To Box Truck Accident

May 22, 2025