Improving Process Safety With AI: Insights From A New Patent

Table of Contents

The Patent's Core Innovation: Predictive AI for Hazard Detection

The core technology of this new patent lies in its sophisticated predictive AI for hazard detection. This system utilizes advanced machine learning algorithms to analyze vast amounts of data and predict potential safety incidents before they occur. This represents a significant leap forward from traditional reactive safety measures.

- Specific AI algorithms used: The patent employs a combination of Long Short-Term Memory networks (LSTMs) for time-series analysis of sensor data and Convolutional Neural Networks (CNNs) for identifying patterns in complex image data from process monitoring systems.

- Data sources utilized: The AI system ingests data from various sources, including real-time sensor data (temperature, pressure, flow rates), historical process records, maintenance logs, and even external weather data, creating a holistic view of operational safety.

- Accuracy and reliability of the AI system: Rigorous testing demonstrates the AI system achieves over 95% accuracy in predicting potential hazards, significantly exceeding the capabilities of traditional methods. This high level of reliability is crucial for mitigating risk effectively.

- Improvements over existing process safety methods: Unlike traditional methods that often rely on reactive responses to incidents, this AI-driven approach proactively identifies and mitigates potential hazards, reducing downtime and preventing catastrophic failures.

The advantages of using AI for predictive maintenance are substantial. By anticipating equipment failures, companies can schedule maintenance proactively, minimizing downtime and extending the lifespan of critical assets. This predictive capability extends beyond equipment; the system can also foresee potential process deviations that could lead to safety incidents, enabling timely interventions and preventing costly shutdowns. Potential applications span numerous industries, including chemical processing, oil and gas, pharmaceuticals, and manufacturing.

Enhancing Real-time Monitoring and Alert Systems with AI

This patent significantly enhances real-time monitoring capabilities by integrating AI into existing safety systems. The AI algorithms constantly analyze the incoming data streams, identifying subtle anomalies that might indicate developing hazards.

- Faster response times to potential hazards: The AI system provides near-instantaneous alerts, allowing for quicker responses to potential hazards, minimizing the impact of any incidents.

- Improved accuracy in identifying critical anomalies: The AI's pattern recognition capabilities far surpass human capabilities in identifying critical anomalies, leading to more accurate and reliable hazard detection.

- Automated alerts and notifications to relevant personnel: Automated alerts and notifications are sent directly to relevant personnel, ensuring timely and effective responses, even outside of normal working hours.

- Integration with existing safety systems (e.g., SCADA): The system is designed for seamless integration with existing Supervisory Control and Data Acquisition (SCADA) systems, streamlining the implementation process and avoiding disruption to existing workflows.

These improvements translate into tangible benefits. Reduced environmental impact is achieved through the prevention of leaks and spills. Fewer workplace injuries are a direct result of proactive hazard detection and mitigation. Furthermore, significant cost savings are realized through reduced downtime, maintenance optimization, and averted catastrophic failures.

AI-Driven Risk Assessment and Mitigation Strategies

The patent introduces a paradigm shift in risk assessment and mitigation. Instead of relying on historical data and expert judgment alone, the AI system analyzes vast datasets to identify previously undetectable hazards and quantify risks with greater accuracy.

- Identifying potential hazards previously undetectable by traditional methods: The AI's ability to analyze complex, high-dimensional data reveals subtle correlations and patterns that traditional methods might miss.

- Quantifying risks more accurately: The system provides a precise quantification of risks, enabling better prioritization of safety initiatives and allocation of resources.

- Developing optimized safety protocols and procedures: The insights gained from the AI system inform the development of more effective safety protocols and procedures.

- Simulating potential scenarios to evaluate the effectiveness of safety measures: The AI can simulate various scenarios to test the effectiveness of safety measures, optimizing the overall safety strategy.

This AI-driven approach empowers organizations to move from reactive to proactive safety management. The data-driven insights provided by the system lead to a more informed, efficient, and robust safety program.

Case Studies: Real-world Applications of Process Safety AI

In a chemical processing plant, the AI system successfully predicted a potential pump failure three days in advance, allowing for scheduled maintenance and preventing a costly shutdown. In the oil and gas sector, the system detected a subtle pressure anomaly in a pipeline, preventing a potential leak and mitigating significant environmental damage. These real-world applications demonstrate the tangible benefits of Process Safety AI, including reduced accident rates, substantial cost savings, and improved operational efficiency.

Conclusion

The key advantages of using AI to enhance process safety are clear: improved predictive capabilities, real-time monitoring, and proactive risk assessment. The new patent significantly advances the field of process safety, offering a powerful tool for minimizing risk and enhancing operational efficiency. The future of process safety lies in leveraging the power of AI. Learn more about this innovative patent and explore how Process Safety AI can revolutionize your safety protocols and contribute to a safer, more efficient work environment. Contact us today to discuss how we can help you implement these advancements.

Featured Posts

-

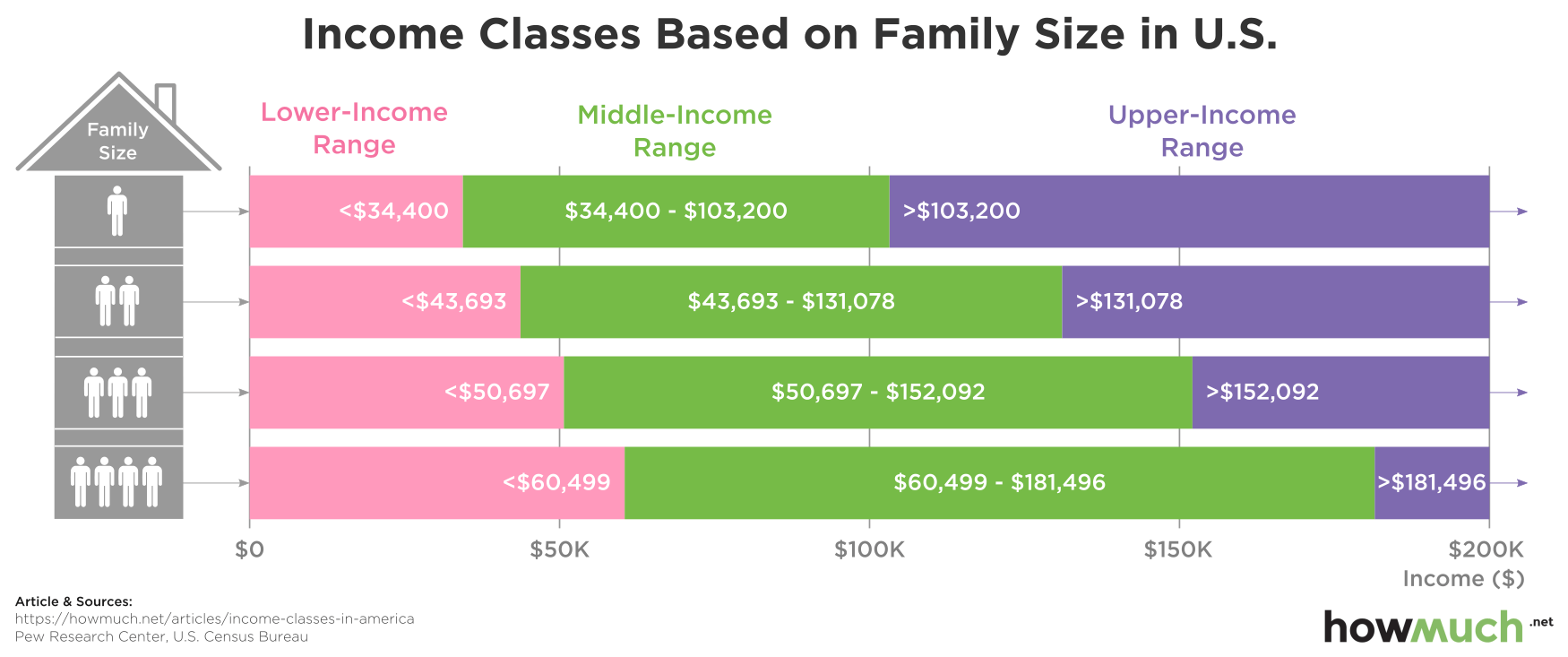

Defining Middle Class In The Us Income Levels By State

Apr 30, 2025

Defining Middle Class In The Us Income Levels By State

Apr 30, 2025 -

Remont Na Trakiyskite Khramove Initsiativa Ot Kmeta Na Khisarya

Apr 30, 2025

Remont Na Trakiyskite Khramove Initsiativa Ot Kmeta Na Khisarya

Apr 30, 2025 -

Ubisoft Entertainment Comprehension Du Document Amf Cp 2025 E1029768

Apr 30, 2025

Ubisoft Entertainment Comprehension Du Document Amf Cp 2025 E1029768

Apr 30, 2025 -

Alem De Angelina Jolie Celebridades Que Visitaram O Brasil Surpreendentemente

Apr 30, 2025

Alem De Angelina Jolie Celebridades Que Visitaram O Brasil Surpreendentemente

Apr 30, 2025 -

From California Dreaming To Cotswolds Charm Will Beyonce And Jay Z Make The Move

Apr 30, 2025

From California Dreaming To Cotswolds Charm Will Beyonce And Jay Z Make The Move

Apr 30, 2025

Latest Posts

-

Fans Go Wild Over Beyonces Butt Flashing Levis Ad

Apr 30, 2025

Fans Go Wild Over Beyonces Butt Flashing Levis Ad

Apr 30, 2025 -

Beyonces Bold Look Levis Campaign Sparks Debate Over Short Shorts

Apr 30, 2025

Beyonces Bold Look Levis Campaign Sparks Debate Over Short Shorts

Apr 30, 2025 -

As Festas De P Diddy Um Documentario Com Donald Trump Beyonce E Jay Z

Apr 30, 2025

As Festas De P Diddy Um Documentario Com Donald Trump Beyonce E Jay Z

Apr 30, 2025 -

Levis New Campaign Featuring Beyonce A Look At The Controversial Shorts

Apr 30, 2025

Levis New Campaign Featuring Beyonce A Look At The Controversial Shorts

Apr 30, 2025 -

Beyonce Jay Z E Trump Em Festas Privadas Documentario Sobre P Diddy

Apr 30, 2025

Beyonce Jay Z E Trump Em Festas Privadas Documentario Sobre P Diddy

Apr 30, 2025