Meet The Cricket Bat Master: Preserving A Legacy

Table of Contents

A History Steeped in Tradition: The Evolution of Cricket Bat Making

The history of cricket bat making is a fascinating journey, reflecting the evolution of the game itself. Early bats were far simpler than their modern counterparts. Initially crafted from various readily available woods, they lacked the sophisticated design and refined materials we see today. The introduction of English willow, with its unique combination of strength and lightness, marked a pivotal moment. This superior wood dramatically improved bat performance, paving the way for the powerful strokes and precise shots we associate with modern cricket.

- Early methods and materials: Bats were often made from readily available woods like ash or pear, resulting in heavier, less durable implements.

- Introduction of English Willow: This marked a significant advancement, offering a lighter, stronger, and more responsive bat.

- Modern techniques and technologies: The use of advanced tools and techniques, including computer-aided design (CAD), has refined the manufacturing process. However, many master craftsmen still rely on their hands and traditional expertise.

Keywords: cricket bat history, traditional cricket bat making, English willow, cricket bat craftsmanship

The Art and Science of Cricket Bat Making: A Master Craftsman's Techniques

Crafting a cricket bat is a meticulous process, a blend of art and science honed over generations. It begins with the careful selection of the finest grade English willow, a process demanding an expert eye to identify the perfect grain and density. The craftsman then expertly shapes the wood, utilizing both hand tools and specialized machinery, to achieve the desired profile, weight, and balance. This is followed by the crucial knocking-in process, a time-consuming method of gently compressing the wood fibers to enhance its durability and resilience. Finally, the bat receives its final finishes, often including a protective coating and the maker's branding, marking it as a testament to exceptional craftsmanship.

- Selecting the right piece of English willow: This step involves careful assessment of the wood's grain, density, and overall quality.

- Shaping the bat using hand tools and machines: A combination of traditional techniques and modern tools ensures precision and efficiency.

- The crucial knocking-in process: This painstaking process compresses the wood fibers, making the bat more durable and responsive.

- Applying the final finishes and branding: A protective coating and the maker's unique mark add the final touches.

Keywords: cricket bat making process, English willow selection, cricket bat crafting, knocking-in process, cricket bat finishing

Challenges and Opportunities: Preserving the Legacy of Cricket Bat Making

The future of cricket bat making faces a number of significant challenges. The rise of mass-produced bats offers cheaper alternatives, putting pressure on traditional craftsmen. Sourcing high-quality English willow is becoming increasingly difficult due to dwindling supplies and environmental concerns. Furthermore, passing down the intricate skills and knowledge of this ancient craft to the next generation presents a considerable hurdle. However, opportunities exist to preserve this rich tradition. Apprenticeships, workshops, and collaborations can help train new generations of cricket bat makers. Adopting sustainable practices in sourcing and manufacturing ensures the long-term viability of the craft.

- Competition from cheaper, mass-produced bats: This poses a significant threat to traditional cricket bat makers.

- The dwindling supply of high-quality English willow: Sustainability concerns and decreasing availability necessitate innovative sourcing strategies.

- The importance of passing down traditional skills to future generations: Mentorship programs and apprenticeships are crucial to preserving the craft.

- The potential for innovation while maintaining tradition: Embracing technology without compromising traditional techniques ensures the longevity of cricket bat making.

Keywords: cricket bat craftsmanship challenges, preserving traditional skills, sustainable cricket bat making, future of cricket bat making

The Future of Cricket Bat Making: Innovation Meets Tradition

Modern technology, while not replacing the core skills of the master craftsman, can complement traditional methods. Computer-aided design (CAD) allows for greater precision in shaping bats, while advanced materials science could lead to more durable and responsive bats. However, the future of cricket bat making lies in finding the right balance between innovation and tradition, ensuring that the artistry and skill remain central to the process. This blend of old and new guarantees the longevity of this time-honored craft.

Conclusion: Honoring the Cricket Bat Master and Their Legacy

The artistry and skill involved in cricket bat making are undeniable. Preserving this legacy is not just about maintaining a tradition; it's about safeguarding a craft that connects generations of cricket players to the very essence of the game. The challenges are real, but the opportunities for preserving and even enhancing this craft are significant. By appreciating the dedication of the cricket bat master and supporting their craft, we ensure that the satisfying thud of leather on willow continues to resonate for generations to come. Discover the difference a handcrafted cricket bat can make – find a master craftsman near you and experience the legacy firsthand. Support cricket bat makers, buy handcrafted cricket bats, and help preserve the cricket bat making tradition.

Keywords: handcrafted cricket bats, support cricket bat makers, preserve cricket bat making tradition, buy handcrafted cricket bats

Featured Posts

-

Big Rig Rock Report 3 12 Key Takeaways From Rock 106 1

May 23, 2025

Big Rig Rock Report 3 12 Key Takeaways From Rock 106 1

May 23, 2025 -

Cat Deeleys Denim Dress Recreate Her This Morning Cowboy Style

May 23, 2025

Cat Deeleys Denim Dress Recreate Her This Morning Cowboy Style

May 23, 2025 -

Valerie Rodriguez Erazo Nueva Secretaria Del Daco

May 23, 2025

Valerie Rodriguez Erazo Nueva Secretaria Del Daco

May 23, 2025 -

Rock 101 Deconstructed Big Rig Rock Report 3 12 Analysis

May 23, 2025

Rock 101 Deconstructed Big Rig Rock Report 3 12 Analysis

May 23, 2025 -

Da Li Je Vanja Mijatovic Zaista Promenila Ime

May 23, 2025

Da Li Je Vanja Mijatovic Zaista Promenila Ime

May 23, 2025

Latest Posts

-

The Impact Of Personal Life On A Man Utd Players Performance

May 23, 2025

The Impact Of Personal Life On A Man Utd Players Performance

May 23, 2025 -

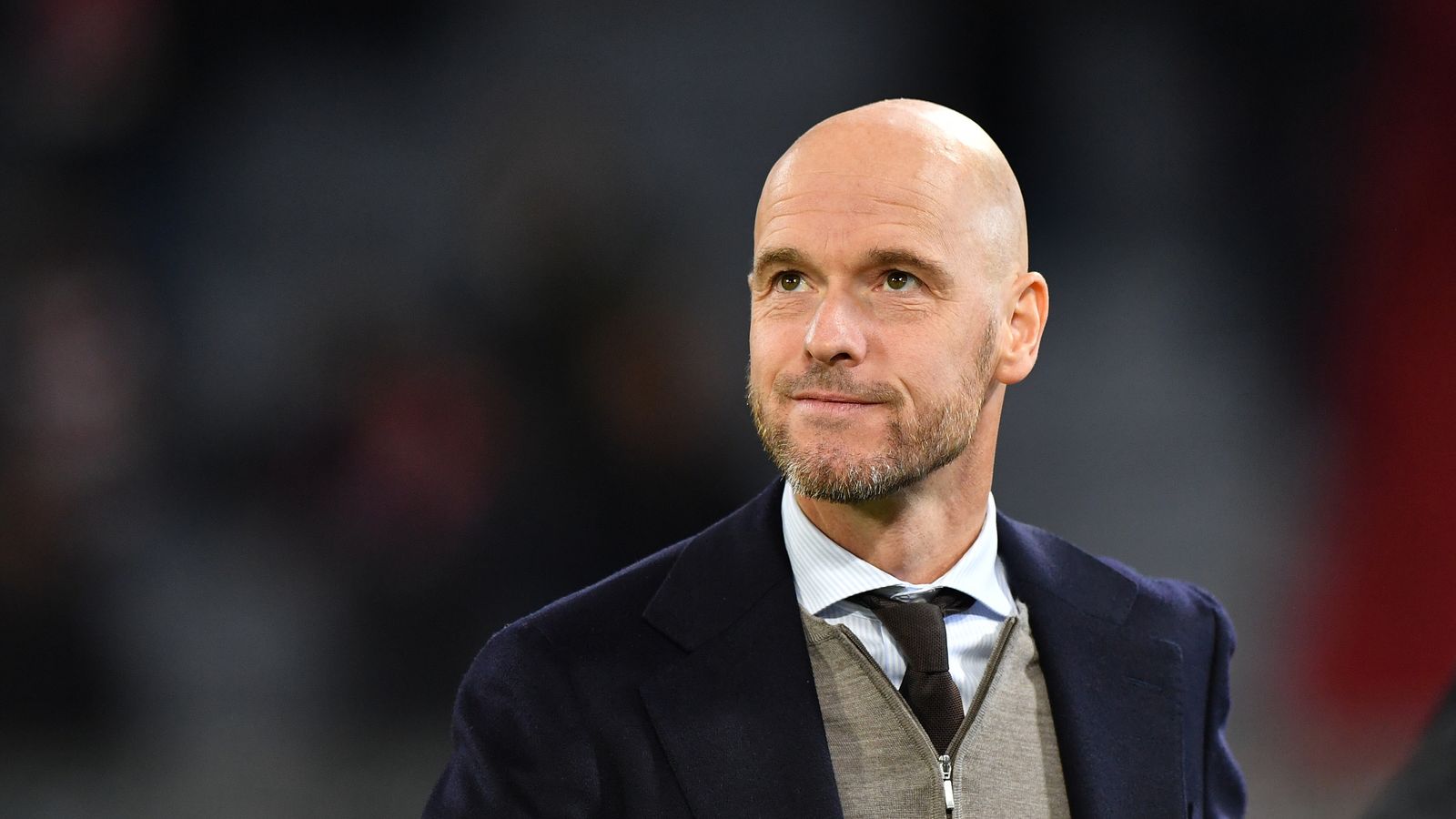

Ten Hag Linked With Juventus Managerial Role After Mottas Exit

May 23, 2025

Ten Hag Linked With Juventus Managerial Role After Mottas Exit

May 23, 2025 -

Former Man Utd Player Personal Issues Behind Failed Spell

May 23, 2025

Former Man Utd Player Personal Issues Behind Failed Spell

May 23, 2025 -

Is Erik Ten Hag The Next Juventus Manager Latest News And Speculation

May 23, 2025

Is Erik Ten Hag The Next Juventus Manager Latest News And Speculation

May 23, 2025 -

Man Utd Flop Blames Poor Form On Personal Life

May 23, 2025

Man Utd Flop Blames Poor Form On Personal Life

May 23, 2025