SG Wireless Strengthens Manufacturing Partnerships To Address OEM Supply Chain Challenges

Table of Contents

Strengthening Strategic Manufacturing Alliances

Resilience in the face of global uncertainty is paramount. For SG Wireless, this means building strong, diverse, and reliable manufacturing partnerships. Strategic partnerships are the cornerstone of our approach to mitigating supply chain risks. We've taken several key actions to achieve this:

- Supply Chain Diversification: We've diversified our manufacturing bases geographically, reducing our reliance on any single region and mitigating the impact of localized disruptions. This includes establishing partnerships with manufacturers in multiple countries across different continents.

- Long-Term Contracts: We've established long-term contracts with key suppliers, ensuring a stable flow of essential components and materials. These agreements provide price stability and predictable delivery schedules, crucial for effective strategic sourcing.

- Increased Investment in Supplier Relationships: We've significantly increased our investment in fostering collaborative relationships with our suppliers. This includes regular communication, joint problem-solving sessions, and mutual support initiatives. This collaborative approach enables us to anticipate and address potential issues proactively.

- Joint Development Programs: We're engaged in joint development programs with our strategic partners, fostering innovation and improving efficiency throughout the entire supply chain. This collaboration results in improved product quality and reduced lead times.

These actions have yielded significant benefits, including reduced lead times, improved quality control through enhanced risk mitigation strategies, and significantly enhanced supply chain predictability.

Investing in Advanced Manufacturing Technologies

Technological advancements are crucial for building a resilient and efficient supply chain. SG Wireless is committed to leveraging the latest technologies to enhance our capabilities and mitigate risks. Key investments include:

- Automation in Manufacturing: We are embracing automation and robotics in our manufacturing processes to improve efficiency, reduce reliance on manual labor, and increase production capacity. This also enhances consistency and minimizes human error.

- Advanced Quality Control Systems: We've implemented advanced quality control systems to ensure consistent product quality and reduce defects. This includes automated inspection systems and real-time data analysis.

- Predictive Analytics: Our investment in predictive analytics and sophisticated data analysis allows for better forecasting of demand, optimizing inventory management, and minimizing stockouts. This provides enhanced supply chain visibility.

These technology investments have resulted in significant improvements in efficiency, speed, and product quality, providing a more agile and responsive supply chain.

Enhanced Transparency and Communication within the Supply Chain

Open communication and information sharing are vital for a robust supply chain. SG Wireless has implemented several initiatives to enhance transparency and collaboration:

- Real-Time Tracking System: We've implemented a sophisticated real-time tracking system for all materials and components throughout the supply chain. This provides complete visibility into the location and status of every item, enabling proactive issue resolution.

- Proactive Communication: Regular communication and collaboration with our suppliers are fundamental to our approach. This includes daily updates, proactive identification of potential problems, and joint solutions development. Our collaborative supply chain management approach is key to our success.

- Enhanced Data Sharing and Analytics: We leverage advanced data analytics to improve the accuracy of our demand forecasting and inventory management. This data-driven approach allows us to anticipate potential disruptions and take proactive measures to mitigate their impact, significantly improving supply chain transparency.

These enhanced communication and collaboration initiatives have significantly improved our ability to respond quickly and effectively to disruptions, ensuring the uninterrupted flow of materials and components.

Building a More Resilient and Sustainable Supply Chain

Our commitment extends beyond immediate challenges. We are building a more resilient and sustainable supply chain for the long term, focusing on:

- Ethical Sourcing Practices: We are committed to ethical sourcing practices, ensuring fair labor conditions and environmentally responsible manufacturing throughout our supply chain. This forms a critical component of our sustainable supply chain strategy.

- Environmental Sustainability: We are continually striving to minimize our environmental impact through initiatives promoting energy efficiency, waste reduction, and the use of sustainable materials. This commitment underscores our belief in responsible and ethical sourcing.

- Continuous Improvement Initiatives: We are continuously evaluating and improving our processes to enhance resilience, efficiency, and sustainability. This commitment ensures we remain adaptable and prepared for future challenges.

Building a robust and sustainable supply chain provides long-term benefits for SG Wireless, our customers, and the environment, solidifying our commitment to responsible business practices and supply chain resilience.

Conclusion

SG Wireless's proactive approach to strengthening manufacturing partnerships demonstrates a commitment to overcoming OEM supply chain challenges. By diversifying manufacturing bases, investing in advanced technologies, improving communication, and prioritizing sustainability, SG Wireless ensures a reliable and resilient supply chain for its OEM partners. This strategy not only safeguards the delivery of high-quality products but also strengthens its position as a dependable and innovative leader in the industry.

Learn more about how SG Wireless is addressing OEM supply chain challenges and building a more resilient future. Contact us today to discuss your supply chain needs and discover how our strengthened manufacturing partnerships can benefit your business. Explore our solutions for robust and reliable OEM supply chain management.

Featured Posts

-

Charlene De Monaco Y Su Sofisticado Look De Lino Otonal

May 26, 2025

Charlene De Monaco Y Su Sofisticado Look De Lino Otonal

May 26, 2025 -

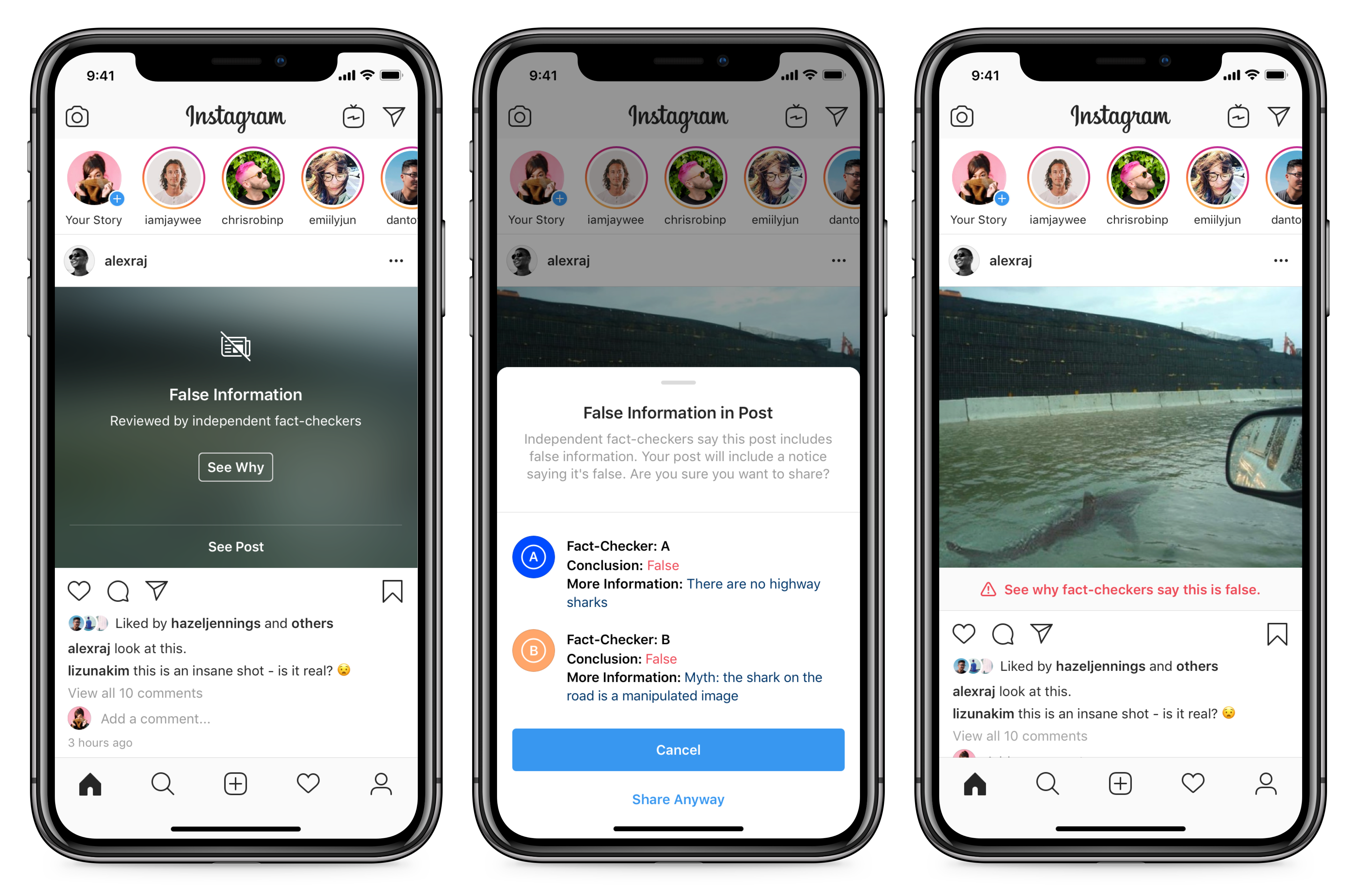

Combattre La Desinformation Le Role De La Rtbf Pour La Journee Mondiale Du Fact Checking

May 26, 2025

Combattre La Desinformation Le Role De La Rtbf Pour La Journee Mondiale Du Fact Checking

May 26, 2025 -

Saksikan Live Trans7 Sprint Race Moto Gp Inggris Rins Pecah Rekor Marquez Jatuh

May 26, 2025

Saksikan Live Trans7 Sprint Race Moto Gp Inggris Rins Pecah Rekor Marquez Jatuh

May 26, 2025 -

Finding Strength In Sorrow Jonathan Peretzs Journey After A Year Of Loss

May 26, 2025

Finding Strength In Sorrow Jonathan Peretzs Journey After A Year Of Loss

May 26, 2025 -

Uefa Nin Real Madrid Sorusturmasi Ne Bekleniyor

May 26, 2025

Uefa Nin Real Madrid Sorusturmasi Ne Bekleniyor

May 26, 2025

Latest Posts

-

Ghwtshy Tewd Ila Jdhwrha Fy Flwrnsa Erd Krwz 2026

May 27, 2025

Ghwtshy Tewd Ila Jdhwrha Fy Flwrnsa Erd Krwz 2026

May 27, 2025 -

Everton Newcastle West Ham Battle For Emegha

May 27, 2025

Everton Newcastle West Ham Battle For Emegha

May 27, 2025 -

Mona Gucci Why Tik Tokers Arent Celebrities Featuring Asantewaa Efia Odo And More

May 27, 2025

Mona Gucci Why Tik Tokers Arent Celebrities Featuring Asantewaa Efia Odo And More

May 27, 2025 -

Ghwtshy Flwrnsa Erd Krwz 2026 Yhtfy Baltarykh Walirth

May 27, 2025

Ghwtshy Flwrnsa Erd Krwz 2026 Yhtfy Baltarykh Walirth

May 27, 2025 -

Gucci Re Web Gradient Blue Gg Supreme 838949 Faev 58460 A Closer Look

May 27, 2025

Gucci Re Web Gradient Blue Gg Supreme 838949 Faev 58460 A Closer Look

May 27, 2025