The Auto Industry's Growing Resistance To EV Sales Requirements

Table of Contents

The global push towards electric vehicles (EVs) is accelerating, with many governments implementing stringent EV sales requirements and mandates. However, this rapid transition is meeting significant resistance from the auto industry, raising concerns about economic viability, consumer readiness, and workforce implications. The industry argues that the aggressive timelines and substantial investments needed for a complete shift away from internal combustion engine (ICE) vehicles are unrealistic and potentially harmful. This article explores the key arguments behind the auto industry's growing resistance to these EV sales requirements.

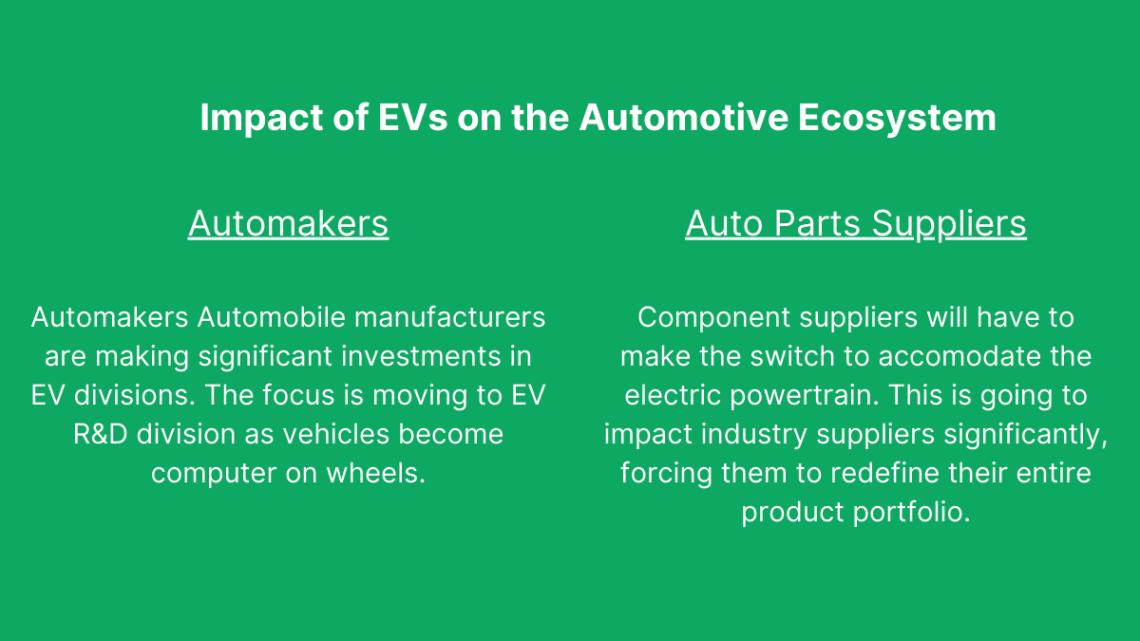

<h2>High Upfront Costs and Investment Barriers for Automakers</h2>

The transition to electric vehicle production represents a massive undertaking for automakers, requiring substantial financial investments and overcoming significant hurdles.

<h3>Massive Capital Expenditure for EV Production</h3>

Shifting from ICE vehicle production to EVs necessitates colossal capital expenditure. Automakers must invest heavily in:

- Retooling existing factories: Adapting assembly lines to accommodate the different manufacturing processes involved in EV production is incredibly costly.

- Developing new EV platforms: Designing and engineering entirely new platforms optimized for electric powertrains requires significant R&D investment.

- Establishing battery production facilities: Battery production is a complex and capital-intensive process, requiring large-scale manufacturing facilities and specialized expertise.

- Investing in charging infrastructure: Automakers are increasingly investing in charging networks to support their EV sales, adding to their financial burdens.

The investment required for EV production dwarfs that needed for ICE vehicles. This disparity particularly impacts smaller automakers with fewer resources, potentially forcing them out of the market.

<h3>Supply Chain Challenges and Raw Material Shortages</h3>

The EV industry faces significant supply chain vulnerabilities and raw material shortages. The reliance on specific countries for crucial raw materials like lithium and cobalt creates geopolitical risks and price volatility.

- Geopolitical implications: The dominance of certain nations in the supply of critical minerals presents geopolitical challenges and risks to supply chain stability.

- Fluctuating raw material prices: The price volatility of these materials directly impacts EV production costs, making it difficult for manufacturers to plan long-term investments.

- Supply chain diversification efforts: Automakers are actively seeking to diversify their supply chains and explore alternative materials to mitigate these risks, but this takes time and investment.

<h2>Concerns Regarding Consumer Demand and Market Readiness</h2>

While the demand for electric vehicles is growing, several factors hinder widespread adoption and raise concerns about market readiness.

<h3>Range Anxiety and Charging Infrastructure Gaps</h3>

One major barrier to EV adoption is range anxiety—the fear of running out of battery power before reaching a charging station. This concern is amplified by the uneven distribution of charging infrastructure, particularly in rural areas.

- Low EV adoption rates in certain regions: Consumer surveys consistently highlight range anxiety and lack of charging infrastructure as key reasons for hesitancy towards EV adoption.

- Government investment in charging infrastructure: Significant public investment in expanding and improving charging infrastructure is crucial for boosting EV adoption rates.

- Technological advancements addressing range anxiety: Innovations in battery technology are steadily increasing EV range, mitigating concerns about limited driving distances.

<h3>High Purchase Prices and Affordability Issues</h3>

Currently, EVs are generally more expensive than comparable gasoline-powered vehicles, posing an affordability challenge for many consumers.

- Government incentives and subsidies: Government subsidies and tax credits are vital in making EVs more accessible to a broader range of consumers.

- Growth of the used EV market: The development of a robust used EV market is essential for lowering the overall cost of EV ownership.

- Impact of battery technology advancements on cost: Advancements in battery technology are steadily driving down the cost of batteries, a major component of EV pricing.

<h2>The Impact on Employment and the Automotive Workforce</h2>

The transition to EVs has significant implications for employment within the automotive sector.

<h3>Job Displacement in the ICE Vehicle Sector</h3>

The decline in ICE vehicle production will inevitably lead to job losses in manufacturing and maintenance.

- Workforce retraining and reskilling programs: Investing in comprehensive retraining programs is crucial to help displaced workers transition to new roles within the EV industry or other sectors.

- Creation of new jobs in the EV sector: While job losses are expected in some areas, the EV industry is creating new employment opportunities in manufacturing, technology, and infrastructure development.

- The importance of a just transition: Ensuring a just transition for workers is critical, protecting livelihoods and fostering social equity.

<h3>The Need for Skilled Labor in EV Manufacturing and Maintenance</h3>

EV manufacturing and maintenance require specialized skills, creating a need for substantial workforce development initiatives.

- Education and training initiatives: Collaborations between educational institutions and automakers are crucial for developing the necessary skills and training programs.

- Government support for workforce development: Government funding for training and education programs is essential for ensuring a sufficient supply of skilled workers to meet the growing demand.

<h2>Conclusion</h2>

The auto industry's resistance to stringent EV sales requirements stems from significant economic challenges, consumer concerns, and workforce transition issues. High upfront costs, supply chain vulnerabilities, range anxiety, affordability concerns, and the potential for job displacement all contribute to the industry's hesitation. Understanding the nuances of EV sales requirements and navigating the transition to EVs responsibly requires a balanced approach. Finding a sustainable path for electric vehicle adoption involves fostering innovation, investing in infrastructure, supporting workforce development, and implementing policies that incentivize both manufacturers and consumers. We urge readers to research further and participate in the public discourse surrounding these critical issues, working towards solutions that promote the adoption of electric vehicles while mitigating the negative consequences of overly aggressive mandates.

Featured Posts

-

Celebrity Family Goldblums At The Como 1907 Vs Torino Game

May 06, 2025

Celebrity Family Goldblums At The Como 1907 Vs Torino Game

May 06, 2025 -

Pratt On Schwarzeneggers Full Frontal A Surprising Endorsement

May 06, 2025

Pratt On Schwarzeneggers Full Frontal A Surprising Endorsement

May 06, 2025 -

Venices Future Addressing The Threat Of Rising Sea Levels

May 06, 2025

Venices Future Addressing The Threat Of Rising Sea Levels

May 06, 2025 -

Romania Election Runoff Far Right Vs Centrist Mayor

May 06, 2025

Romania Election Runoff Far Right Vs Centrist Mayor

May 06, 2025 -

Brazil Arrests In Lady Gaga Bomb Plot Investigation Details Lgbtq Targeting And Satanic Ritual

May 06, 2025

Brazil Arrests In Lady Gaga Bomb Plot Investigation Details Lgbtq Targeting And Satanic Ritual

May 06, 2025

Latest Posts

-

Virtual Concert Sabrina Carpenter Headlines Fortnite Festival

May 06, 2025

Virtual Concert Sabrina Carpenter Headlines Fortnite Festival

May 06, 2025 -

Sabrina Carpenters Fortnite Performance Details And Fan Reactions

May 06, 2025

Sabrina Carpenters Fortnite Performance Details And Fan Reactions

May 06, 2025 -

Fortnite Season 8 Music Festival Features Sabrina Carpenter

May 06, 2025

Fortnite Season 8 Music Festival Features Sabrina Carpenter

May 06, 2025 -

Fortnites Next Big Event Sabrina Carpenters Virtual Concert

May 06, 2025

Fortnites Next Big Event Sabrina Carpenters Virtual Concert

May 06, 2025 -

Fortnite Season 8 Sabrina Carpenter Confirmed As Headliner

May 06, 2025

Fortnite Season 8 Sabrina Carpenter Confirmed As Headliner

May 06, 2025