The Cricket Bat Maker: Skill And Heritage Combined

Table of Contents

Selecting the Perfect Willow

The journey of a handcrafted cricket bat begins with the selection of the perfect willow. This is arguably the most crucial step, determining the bat's overall performance and longevity. The choice typically lies between English willow and Kashmir willow, each possessing distinct characteristics. Understanding willow grading is also paramount.

-

English Willow vs. Kashmir Willow: English willow is renowned for its superior strength and resilience, making it a preferred choice for professional players. Kashmir willow, while often lighter, offers a more powerful strike. The choice often depends on the player's preference and playing style.

-

Willow Grading: Willow is graded based on its density, straightness of grain, and the absence of blemishes. Grade 1 willow, the highest grade, boasts the closest, most consistent grain, resulting in a more powerful and durable bat. Lower grades are still suitable but may have slightly less power and longevity.

-

Visual Inspection: Experienced cricket bat makers meticulously inspect each piece of willow, looking for subtle imperfections that could impact the bat's performance. They examine the grain's density, searching for knots, cracks, or inconsistencies that could weaken the wood. This visual assessment is crucial in ensuring only the finest willow makes it into a handcrafted cricket bat.

The Art of Shaping and Carving

Once the premium willow is selected, the art of shaping and carving begins. This is where the true skill of the cricket bat maker shines through. Using specialized tools passed down through generations, they meticulously transform the raw willow cleft into the recognizable profile of a cricket bat.

-

Shaping Process: The process involves carefully removing wood from the cleft, shaping it into a bat profile using drawknives, spokeshaves, and other traditional tools. This requires precision and a keen eye for balance and weight distribution.

-

Traditional Tools: The tools employed are often simple yet effective, reflecting the enduring traditions of cricket bat making. These tools, honed over years of use, allow for a level of control and precision that is difficult to match with modern machinery.

-

Bat Profile and Performance: The bat's profile – its shape and dimensions – significantly affects its performance. A carefully crafted profile optimizes sweet spot size, weight distribution, and overall power. The skill of the maker lies in achieving the perfect balance between these factors.

The Crucial Process of Knocking-In

Before a handcrafted cricket bat is ready for the field, it undergoes the crucial knocking-in process. This essential step prepares the willow for impact, increasing its durability and improving its performance.

-

Manual vs. Machine Knocking-In: Traditionally, knocking-in is done manually using a mallet and a ball, gradually hardening the wood. Modern methods utilize machines for a more efficient process, but many makers still favor the traditional approach for a more personalized touch and greater control over the process.

-

Gradual Knocking-In: The importance of gradual knocking-in cannot be overstated. It allows the willow fibers to compress and bind together, preventing cracks and enhancing the bat's resilience to impacts. Rushing this process can lead to significant damage.

-

Signs of a Properly Knocked-In Bat: A properly knocked-in bat will have a slightly darkened surface and a more compressed feel. It will also produce a duller sound when tapped compared to a raw, unknocked-in bat.

Finishing Touches and Personalization

The final stages of cricket bat making involve the finishing touches, adding the handle, grip, and personalized branding. These seemingly minor details significantly impact both the bat's aesthetics and its feel in the hand.

-

Handles and Grips: Different types of handles and grips are available, each providing a unique feel and level of comfort. The choice depends largely on personal preference.

-

Branding and Personalization: Many cricket bat makers offer branding and personalization options, allowing players to add their name, initials, or a special design to their bat. This adds a unique and personal touch to the already handcrafted piece.

-

Quality Finishing: A high-quality finish protects the bat from the elements and enhances its overall aesthetic appeal. This final step is crucial in ensuring that the bat not only performs well but also looks the part.

Conclusion

Creating a handcrafted cricket bat is a testament to the enduring blend of skill, heritage, and precision. From carefully selecting the finest willow to the meticulous application of the final polish, each step showcases the dedication and artistry of the cricket bat maker. The process combines time-honored traditions with modern techniques, resulting in a superior cricket bat that elevates the game. Explore the world of handcrafted cricket bats and discover the difference a truly bespoke cricket bat can make in your game. Find a skilled cricket bat maker who values both heritage and modern techniques – and experience the unique performance and satisfaction that comes with using a truly exceptional, handcrafted willow cricket bat.

Featured Posts

-

X101 5 Big Rig Rock Report 3 12 A Detailed Overview

May 23, 2025

X101 5 Big Rig Rock Report 3 12 A Detailed Overview

May 23, 2025 -

This Morning Cat Deeleys Dress Malfunction Before Live Show

May 23, 2025

This Morning Cat Deeleys Dress Malfunction Before Live Show

May 23, 2025 -

The Karate Kid A Cinematic Exploration Of Mentorship And Self Discovery

May 23, 2025

The Karate Kid A Cinematic Exploration Of Mentorship And Self Discovery

May 23, 2025 -

Royal Albert Hall Hosts Grand Ole Oprys First Ever International Show

May 23, 2025

Royal Albert Hall Hosts Grand Ole Oprys First Ever International Show

May 23, 2025 -

Whats New On Netflix In May 2025

May 23, 2025

Whats New On Netflix In May 2025

May 23, 2025

Latest Posts

-

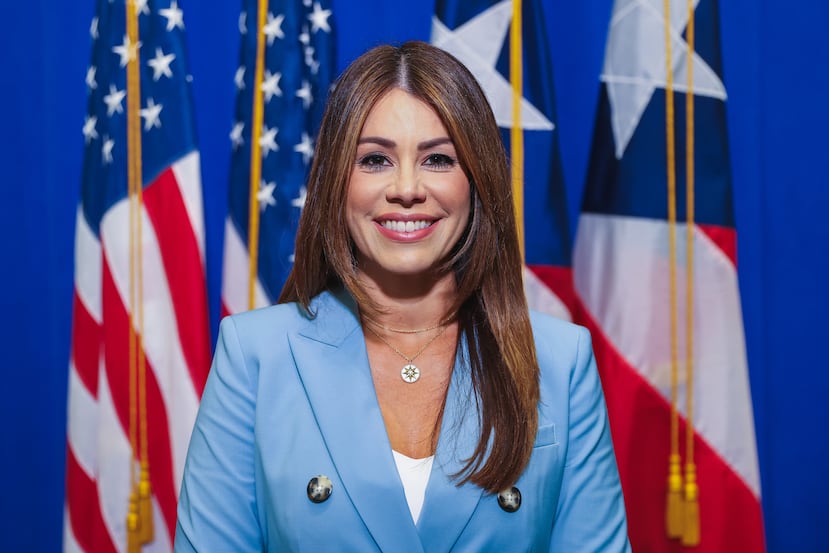

El Senado Aprueba A Valerie Rodriguez Como Nueva Secretaria De Daco

May 23, 2025

El Senado Aprueba A Valerie Rodriguez Como Nueva Secretaria De Daco

May 23, 2025 -

Confirmacion De Valerie Rodriguez Como Secretaria De Daco Detalles Clave

May 23, 2025

Confirmacion De Valerie Rodriguez Como Secretaria De Daco Detalles Clave

May 23, 2025 -

Senado Confirma A Valerie Rodriguez Como Secretaria De Daco

May 23, 2025

Senado Confirma A Valerie Rodriguez Como Secretaria De Daco

May 23, 2025 -

Cambios En El Daco Valerie Rodriguez Erazo Como Nueva Secretaria

May 23, 2025

Cambios En El Daco Valerie Rodriguez Erazo Como Nueva Secretaria

May 23, 2025 -

Succession Sky Atlantic Hd Exploring The Themes And Symbolism

May 23, 2025

Succession Sky Atlantic Hd Exploring The Themes And Symbolism

May 23, 2025