The Future Of Electric Motors: Diversifying Supply Chains Beyond China

Table of Contents

Geopolitical Risks of Concentrated Supply Chains

The current concentration of electric motor production in China presents significant geopolitical risks. This dependence stems from two primary factors: access to rare earth minerals and a vast, highly developed manufacturing base.

Dependence on China's Rare Earth Minerals

China controls a significant portion of the mining and processing of rare earth minerals, vital components in the powerful magnets used within electric motors. Neodymium and dysprosium, for example, are indispensable for high-performance electric motors, and China’s dominance in their supply poses a substantial threat.

- Geopolitical Implications: This dependence creates vulnerabilities to trade disputes, export restrictions, and potential supply chain disruptions. Any political tension or unexpected event could severely impact the global EV industry.

- Market Share Dominance: China’s market share in rare earth mineral processing exceeds 80%, a figure that highlights the urgent need for diversification.

- Alternative Sources and Limitations: While other countries possess rare earth mineral deposits, extracting and refining them to the required purity and scale presents significant technical and economic hurdles. Australia, Brazil, and the US are attempting to increase their production, but it's a long-term endeavor.

Manufacturing Capacity and Expertise

Beyond rare earth minerals, China's dominance extends to the manufacturing of electric motors themselves. The country benefits from cost-effective manufacturing, a large pool of skilled labor, and established supply chains. However, this concentration carries significant drawbacks.

- Advantages of China's Manufacturing: Lower labor costs and a mature manufacturing ecosystem have made China a highly attractive location for electric motor production.

- Drawbacks: Concerns around intellectual property protection, potential for unfair trade practices, and the risk of supply chain disruptions outweigh these advantages. A more geographically diversified manufacturing base is crucial for mitigating these risks.

- Upskilling and Investment: Other nations need substantial investment in upskilling their workforces and modernizing their manufacturing capabilities to compete effectively.

Strategies for Diversification

Diversifying the electric motor supply chain requires a multi-pronged approach involving strategic investments, technological advancements, and fostering regional collaboration.

Investment in Domestic Manufacturing

Governments worldwide are actively incentivizing domestic electric motor production.

- Government Incentives: Substantial subsidies, tax breaks, and infrastructure development are being deployed to attract foreign and domestic investment in electric motor manufacturing facilities.

- Successful Initiatives: The US's Inflation Reduction Act, for instance, provides significant incentives for domestic EV manufacturing, indirectly boosting the electric motor sector. Similar initiatives are underway in Europe and other regions.

Fostering Regional Supply Chains

The concept of "near-shoring" and "friend-shoring" – shifting production to geographically closer and politically aligned nations – is gaining traction.

- Near-shoring and Friend-shoring: This reduces reliance on long and potentially vulnerable supply chains, mitigating transportation costs and geopolitical risks.

- Regional Collaborations: Successful regional collaborations are emerging, with countries pooling resources and expertise to build resilient regional supply chains for electric motors and their components.

Technological Innovation and Automation

Automation and technological advancements offer a pathway to reduce reliance on low-cost labor and improve competitiveness.

- Advanced Manufacturing Technologies: Robotics, AI-powered quality control, and advanced manufacturing processes can enhance efficiency, precision, and overall production output.

- Cost Reduction and Competitiveness: These technologies can significantly reduce production costs and improve the competitiveness of electric motor manufacturing outside of China.

Challenges to Diversification

Despite the clear need for diversification, several significant challenges must be addressed.

Cost Competitiveness

Competing with China's low manufacturing costs is a major hurdle.

- Overcoming Cost Disadvantages: Automation, improved efficiency, and achieving economies of scale are crucial to offsetting China’s cost advantages.

Skilled Labor Shortages

Developing a skilled workforce is paramount.

- Workforce Development: Investing in training programs and partnerships with educational institutions to create a skilled workforce in electric motor manufacturing is vital.

Infrastructure Development

Robust infrastructure is essential to support manufacturing growth.

- Essential Infrastructure: Investment in renewable energy sources to power factories and efficient transportation networks to move goods is crucial for a successful transition.

Conclusion

The over-reliance on China for electric motor production presents substantial geopolitical and economic risks. Diversifying supply chains beyond China is not merely desirable; it's a necessity for the sustainable growth of the EV industry. By implementing strategies that encourage domestic manufacturing, foster regional collaboration, and leverage technological advancements, countries can build more resilient and globally distributed supply chains. Addressing the challenges of cost competitiveness, skilled labor shortages, and infrastructure development is crucial for success. We urge readers to actively engage with and support companies and initiatives committed to building resilient supply chains, diversifying electric motor manufacturing, and reducing reliance on China, ensuring a secure and prosperous future for the electric vehicle revolution.

Featured Posts

-

Le Parc De Batteries D Eneco A Au Roeulx Une Avancee Majeure Pour Le Stockage D Energie En Belgique

May 04, 2025

Le Parc De Batteries D Eneco A Au Roeulx Une Avancee Majeure Pour Le Stockage D Energie En Belgique

May 04, 2025 -

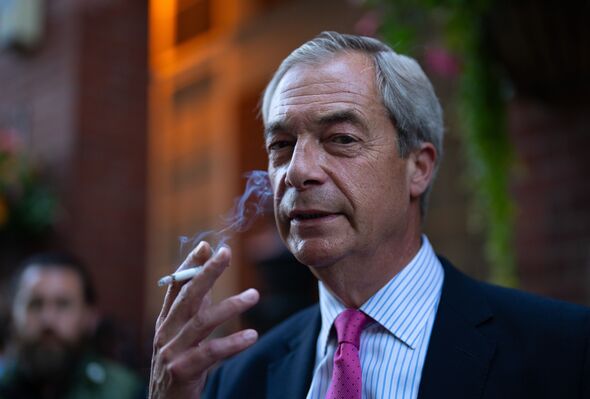

Rupert Lowes Defamation Lawsuit Against Nigel Farage False Allegations

May 04, 2025

Rupert Lowes Defamation Lawsuit Against Nigel Farage False Allegations

May 04, 2025 -

These Electric Motors Reducing Global Reliance On China

May 04, 2025

These Electric Motors Reducing Global Reliance On China

May 04, 2025 -

Nicolai Tangens Response To Trump Era Tariffs

May 04, 2025

Nicolai Tangens Response To Trump Era Tariffs

May 04, 2025 -

Blake Lively Vs Anna Kendrick Unpacking The Rumored Rivalry

May 04, 2025

Blake Lively Vs Anna Kendrick Unpacking The Rumored Rivalry

May 04, 2025

Latest Posts

-

Comparing Styles Blake Lively And Anna Kendricks Understated Red Carpet Looks

May 04, 2025

Comparing Styles Blake Lively And Anna Kendricks Understated Red Carpet Looks

May 04, 2025 -

The Blake Lively And Anna Kendrick Drama A Year By Year Look

May 04, 2025

The Blake Lively And Anna Kendrick Drama A Year By Year Look

May 04, 2025 -

Blake Lively And Anna Kendrick A Timeline Of Their Reported Feud

May 04, 2025

Blake Lively And Anna Kendrick A Timeline Of Their Reported Feud

May 04, 2025 -

Blake Lively And Anna Kendricks Subtle Style Showdown At The Premiere

May 04, 2025

Blake Lively And Anna Kendricks Subtle Style Showdown At The Premiere

May 04, 2025 -

Dispelling Rumors The Truth Behind The Another Simple Favor Set Dynamics

May 04, 2025

Dispelling Rumors The Truth Behind The Another Simple Favor Set Dynamics

May 04, 2025