The Struggle To Create All-American Products: A Realistic Look

Table of Contents

The High Cost of Domestic Manufacturing

One of the most significant barriers to creating All-American products is the high cost of domestic manufacturing. This cost disparity stems from several key factors:

Labor Costs

- Increased minimum wages and benefits: The US has significantly higher minimum wages and benefits compared to many other countries. These added costs directly impact the price of manufactured goods, making them less competitive in the global marketplace.

- Skilled labor shortages: Specific industries face acute shortages of skilled labor, driving up wages even further and potentially slowing down production. This shortage is particularly acute in technologically advanced manufacturing sectors.

- Automation as a potential solution: While automation can mitigate some labor costs, it comes with its own substantial upfront investment and ongoing maintenance expenses, adding another layer of complexity to the equation for All-American products.

Raw Material Sourcing

Sourcing all raw materials domestically presents another significant challenge.

- Dependence on foreign sources: The US relies on foreign sources for many essential raw materials, from rare earth minerals to certain types of textiles. This dependence weakens the ability to create a fully domestic supply chain for many products.

- Environmental and logistical challenges: Domestic sourcing often faces significant environmental and logistical hurdles. Transportation distances are greater, leading to higher fuel costs and a larger carbon footprint. Extracting and processing domestic resources can also have a considerable environmental impact.

- Price volatility and supply chain disruptions: Relying solely on domestic sources exposes businesses to potential price volatility and increased risk of supply chain disruptions due to natural disasters, labor disputes, or other unforeseen events. This inherent risk is a significant drawback to the dream of fully domestic production.

The Complexity of Supply Chains

Beyond manufacturing costs, the complexity of managing a completely domestic supply chain is a major hurdle.

Logistics and Transportation

- Longer transportation distances and higher fuel costs: Shipping materials and finished goods across the vast expanse of the US is significantly more expensive and time-consuming than relying on shorter, international supply chains. The reliance on trucking, in particular, adds to the logistical complexity and costs.

- Increased reliance on trucking and potential delays: The US freight system heavily relies on trucking, making it vulnerable to delays caused by traffic, weather, or driver shortages. This uncertainty makes reliable delivery times challenging and adds to overall production costs.

- The environmental impact of increased transportation: The increased transportation distances inherent in a domestic-only supply chain result in a larger carbon footprint, contradicting the sustainability goals of many consumers who seek environmentally friendly All-American products.

Regulatory Hurdles

Navigating US regulations and compliance adds another layer of complexity and expense.

- Meeting stringent environmental and safety standards: US regulations on environmental protection and product safety are often stricter than those in other countries, increasing the cost of compliance.

- Navigating complex import/export regulations (even for domestic materials): Even sourcing materials domestically involves navigating intricate regulatory processes, particularly when dealing with interstate commerce.

- Time and cost associated with regulatory compliance: The time and resources required to meet these regulations significantly add to the overall cost of production for All-American products, impacting their competitiveness.

Consumer Demand and Perception

Despite the desire for All-American products, consumer behavior and perceptions play a significant role in the challenges faced by domestic manufacturers.

Price Sensitivity

- The willingness of consumers to pay a premium: While there's a growing segment of consumers willing to pay more for domestically-made goods, many remain price-sensitive, opting for cheaper imported alternatives.

- The competition from cheaper, imported alternatives: The vast availability of cheaper imported goods often makes All-American products less appealing to budget-conscious consumers.

- Marketing strategies to highlight the value proposition: Effective marketing is crucial to highlight the value proposition of All-American products – emphasizing quality, durability, ethical labor practices, and environmental sustainability – to justify the higher price tag.

"Made in USA" Labeling and Authenticity

The meaning and application of "Made in USA" labels are often ambiguous and open to interpretation.

- Defining what constitutes "Made in USA": There’s no single, universally accepted definition of "Made in USA," leading to inconsistencies and potential for misrepresentation.

- The need for transparency and clear labeling standards: Clearer, more standardized labeling is needed to ensure transparency and build consumer trust.

- Consumer skepticism and the importance of building trust: Consumer skepticism regarding "Made in USA" claims is prevalent, highlighting the need for manufacturers to build trust through transparency and verifiable proof of domestic origin.

Conclusion

Creating truly All-American products presents a significant challenge, encompassing high manufacturing costs, complex domestic supply chains, and consumer price sensitivity. While the desire for domestically produced goods remains strong, understanding the realities of manufacturing in the US is crucial. Let's work together to promote transparent and genuinely All-American products by supporting companies committed to sustainable and ethical domestic production. By demanding transparency and supporting businesses dedicated to creating authentic All-American products, we can collectively strengthen the domestic manufacturing sector and foster a more resilient and sustainable economy.

Featured Posts

-

Legal Showdown Harvard University Fights Trump Administrations Funding Cuts

Apr 29, 2025

Legal Showdown Harvard University Fights Trump Administrations Funding Cuts

Apr 29, 2025 -

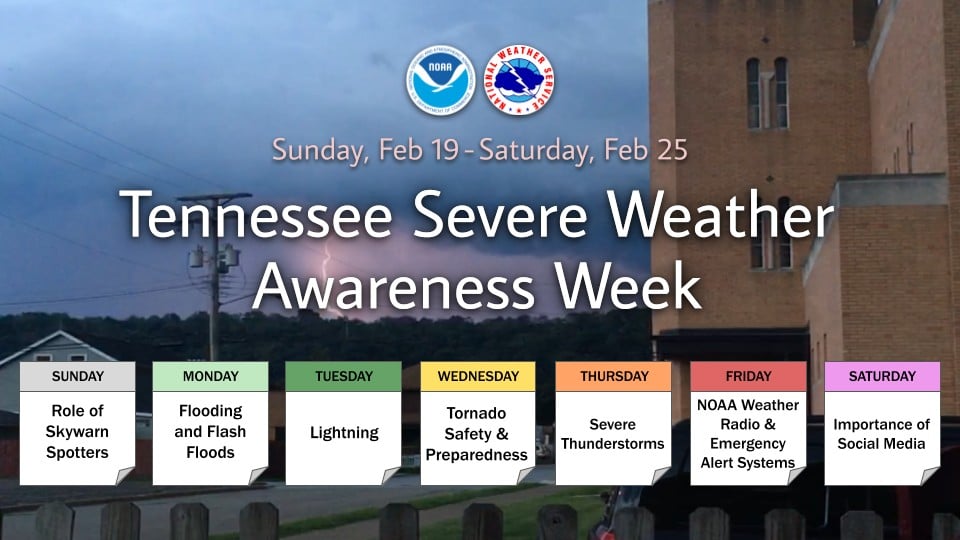

Kentucky Gears Up For Severe Weather Nws Awareness Week Initiatives

Apr 29, 2025

Kentucky Gears Up For Severe Weather Nws Awareness Week Initiatives

Apr 29, 2025 -

Can Trumps Tax Cuts Survive Internal Republican Opposition

Apr 29, 2025

Can Trumps Tax Cuts Survive Internal Republican Opposition

Apr 29, 2025 -

State Of Emergency In Louisville Tornado Damage And Imminent Flood Risk

Apr 29, 2025

State Of Emergency In Louisville Tornado Damage And Imminent Flood Risk

Apr 29, 2025 -

April 27 2025 Nyt Strands Answers Find The Spangram And Solve The Puzzle

Apr 29, 2025

April 27 2025 Nyt Strands Answers Find The Spangram And Solve The Puzzle

Apr 29, 2025

Latest Posts

-

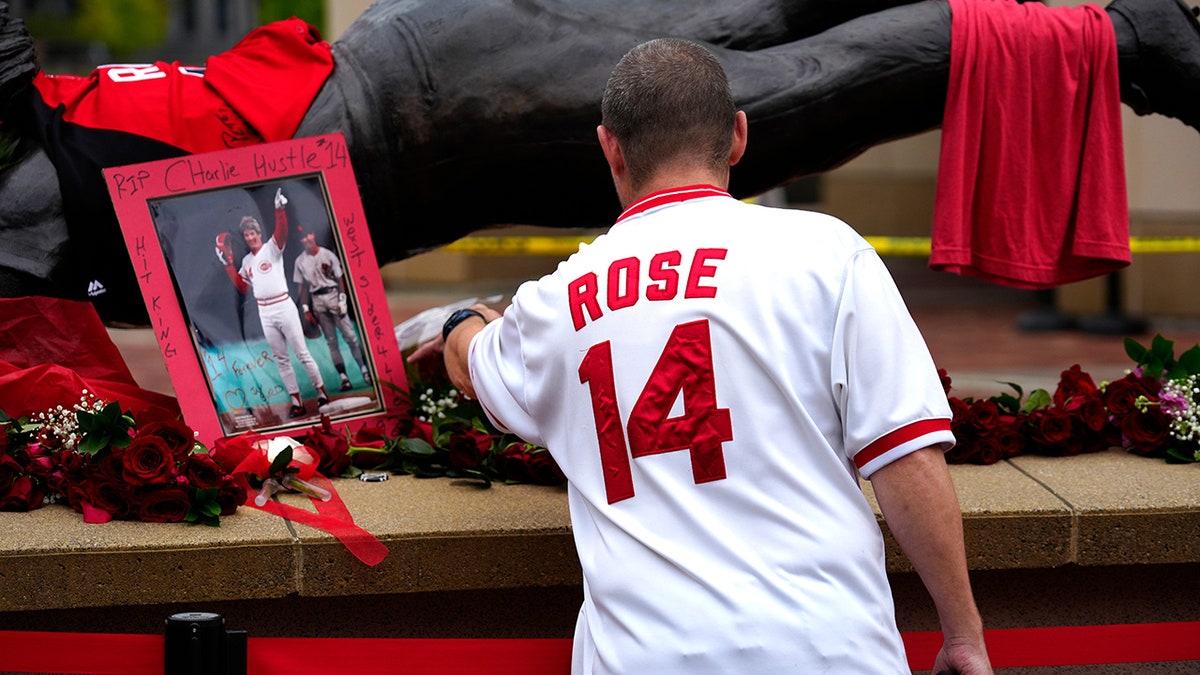

Mlb Considers Petition To Reinstate Pete Rose A Report

Apr 29, 2025

Mlb Considers Petition To Reinstate Pete Rose A Report

Apr 29, 2025 -

President Trumps Potential Pardon Of Pete Rose A Deeper Look

Apr 29, 2025

President Trumps Potential Pardon Of Pete Rose A Deeper Look

Apr 29, 2025 -

Trump To Pardon Pete Rose Posthumously Details And Reactions

Apr 29, 2025

Trump To Pardon Pete Rose Posthumously Details And Reactions

Apr 29, 2025 -

Pete Rose Pardon Trumps Statement And Its Implications

Apr 29, 2025

Pete Rose Pardon Trumps Statement And Its Implications

Apr 29, 2025 -

Trump To Pardon Pete Rose After His Death Examining The Announcement

Apr 29, 2025

Trump To Pardon Pete Rose After His Death Examining The Announcement

Apr 29, 2025