The Technological Barriers To Robotic Nike Shoe Production

Table of Contents

Precision and Dexterity Challenges in Robotic Assembly

The intricate process of shoemaking presents a significant challenge for robotics. The dexterity and precision required to handle diverse materials and assemble complex components are currently beyond the capabilities of most robotic systems.

Complex Material Handling

Robots struggle with the wide variety of materials used in Nike shoe production. Leather, mesh, rubber, synthetics – each possesses unique properties that demand specialized handling techniques.

- Difficulty in handling delicate materials without damage: The soft nature of some materials makes them prone to tearing or stretching during robotic manipulation.

- Need for adaptable robotic grippers for various components: Current grippers often lack the adaptability to securely grasp and manipulate components of varying shapes, sizes, and textures. This requires the development of advanced, sensor-equipped grippers capable of dynamic adjustments.

- Challenges in precise placement and alignment of components: Achieving the necessary precision for seamless assembly requires extremely accurate robotic movements and advanced vision systems. Even slight misalignments can compromise the shoe's structural integrity and aesthetic appeal.

Varied Sewing and Gluing Requirements

Automated stitching and adhesive application for complex shoe designs remain a significant technological bottleneck. Current robotic systems lack the dexterity and adaptability of human hands, particularly when dealing with intricate stitching patterns and precise glue application.

- Limitations of robotic sewing machines in handling diverse fabrics and patterns: Adapting robotic sewing machines to handle the wide range of fabrics and patterns used in Nike shoe designs is a complex engineering problem. The variations in fabric thickness, texture, and elasticity require sophisticated control algorithms.

- Inconsistent glue application leading to potential quality defects: Precise and consistent glue application is crucial for the durability and waterproofness of the shoe. Inconsistent application can lead to weaknesses and potential defects.

- Need for advanced sensors and AI for precise glue dispensing: Advanced sensor systems and AI algorithms are needed to ensure precise and consistent glue application, adapting to varying material types and thicknesses.

Software and AI Limitations in Adaptive Manufacturing

The complexity of shoe design and manufacturing necessitates advanced software and AI capabilities for efficient and adaptable robotic systems. Current technologies fall short in several critical areas.

Programmability and Adaptability

Current robotic systems often require extensive reprogramming for even minor design changes, making them inflexible for the constantly evolving styles and designs of Nike shoes.

- High cost of reprogramming for new shoe models: Reprogramming robots for each new shoe model is time-consuming and expensive, significantly impacting production efficiency and profitability.

- Need for AI-powered systems that can adapt to variations in materials and designs: AI-powered systems are needed to enable robots to adapt to variations in materials, designs, and even slight inconsistencies in the manufacturing process.

- Challenges in creating a universal robotic system for all shoe types: Developing a single robotic system capable of handling the full range of Nike shoe styles and designs is a significant challenge.

Quality Control and Defect Detection

Ensuring consistent quality in a fully automated system requires sophisticated vision systems and AI-powered quality control mechanisms. Current technologies are not yet sufficiently robust to identify and address all potential defects.

- Difficulty in detecting subtle defects in material or assembly: Detecting subtle flaws in materials or assembly often requires human expertise and judgment, which are currently difficult to replicate robotically.

- Need for advanced image processing and machine learning for quality assessment: Advanced image processing and machine learning algorithms are needed to enable robots to accurately assess the quality of assembled shoes and identify potential defects.

- Development of robust systems for automated defect correction or rejection: Robust systems are needed to automatically correct minor defects or reject shoes that fail to meet quality standards.

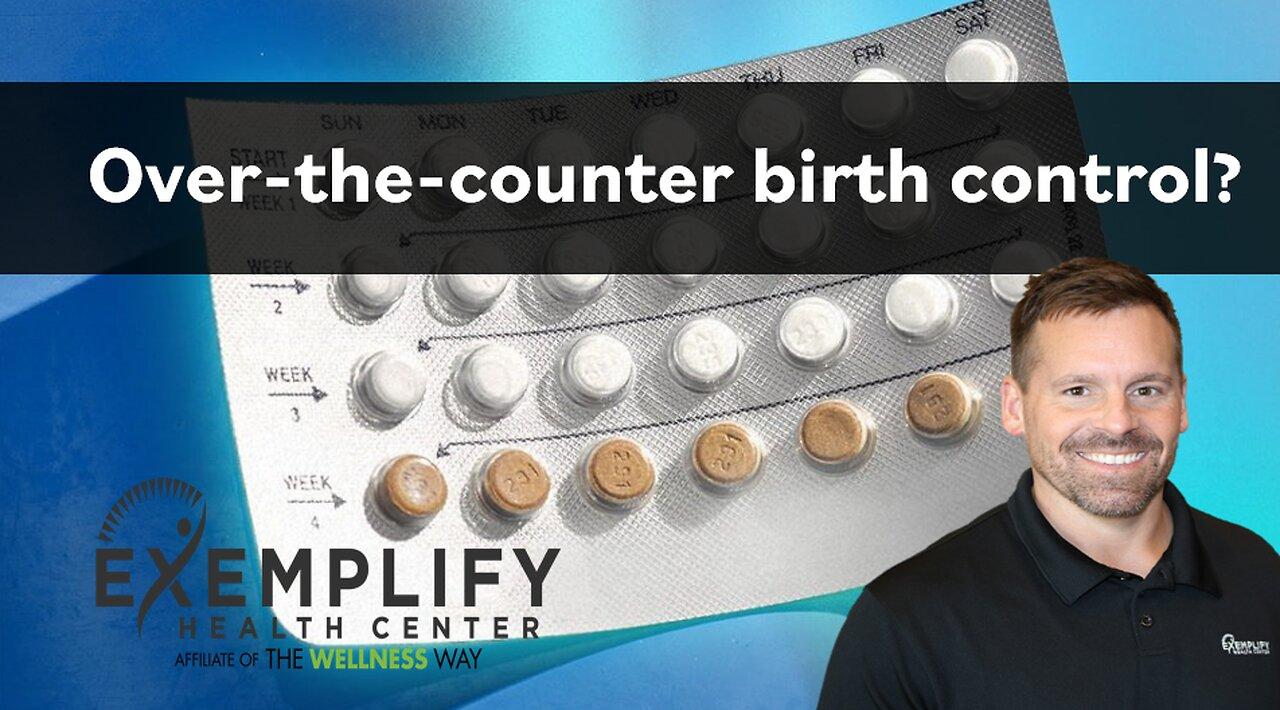

Economic and Infrastructure Barriers to Full Automation

Beyond technological limitations, economic and infrastructural factors pose substantial challenges to the complete robotization of Nike shoe production.

High Initial Investment Costs

The cost of implementing advanced robotic systems and training personnel is a significant barrier, even for a large corporation like Nike.

- High capital expenditure for robotic equipment and software: The initial investment required for purchasing and installing advanced robotic equipment and software is substantial.

- Significant costs associated with integration and maintenance: Integrating robotic systems into existing production lines and ensuring ongoing maintenance adds further costs.

- Need for skilled technicians to operate and maintain the robotic systems: Operating and maintaining complex robotic systems requires highly skilled technicians, adding to labor costs.

Return on Investment (ROI) Uncertainty

Predicting the return on investment (ROI) for such a large-scale automation project is difficult, given the rapid pace of technological change and potential for disruption.

- Uncertainty about the long-term cost-effectiveness of robotic manufacturing: The long-term cost-effectiveness of robotic manufacturing is uncertain, particularly given the potential for rapid technological obsolescence.

- Potential for rapid technological obsolescence: Rapid advancements in robotics and AI could render current investments obsolete relatively quickly.

- Need for careful cost-benefit analysis before implementation: A thorough cost-benefit analysis is crucial before committing to such a large-scale investment.

Conclusion

While the dream of fully robotic Nike shoe production is alluring, significant technological, economic, and infrastructural barriers remain. From the dexterity required for handling diverse materials to the sophisticated software needed for adaptive manufacturing and quality control, the challenges are substantial. Overcoming these hurdles will require continued advancements in robotics, AI, and material science. However, the potential benefits of increased efficiency, precision, and scalability make further research and development in robotic Nike shoe production, and related areas such as automated shoe manufacturing and robotic assembly in the footwear industry, a worthwhile endeavor. Let's continue to explore the innovative solutions that will pave the way for a future of automated footwear manufacturing.

Featured Posts

-

Understanding The Crucial Role Of Middle Managers In Modern Organizations

Apr 22, 2025

Understanding The Crucial Role Of Middle Managers In Modern Organizations

Apr 22, 2025 -

Over The Counter Birth Control Implications For Reproductive Healthcare Post Roe

Apr 22, 2025

Over The Counter Birth Control Implications For Reproductive Healthcare Post Roe

Apr 22, 2025 -

Tik Toks Role In Navigating Post Trump Tariffs

Apr 22, 2025

Tik Toks Role In Navigating Post Trump Tariffs

Apr 22, 2025 -

5 Key Actions To Secure A Role In Todays Booming Private Credit Market

Apr 22, 2025

5 Key Actions To Secure A Role In Todays Booming Private Credit Market

Apr 22, 2025 -

Leaked Signal Messages Reveal Hegseths Military Strategies

Apr 22, 2025

Leaked Signal Messages Reveal Hegseths Military Strategies

Apr 22, 2025