US Port Fees To Wallop Auto Carrier With $70 Million Hit

Table of Contents

The $70 Million Hit: A Breakdown of Increased Port Fees

This significant financial blow stems from a confluence of increased port fees. The $70 million figure represents a dramatic increase in operational costs for the auto carrier, impacting their profitability and potentially their ability to offer competitive pricing. Let's break down the contributing factors:

-

Container Dwell Fees: These fees, levied on containers remaining at the port beyond a specified time, have increased dramatically. The longer containers sit idle due to port congestion, the higher the fees become. For this auto carrier, dwell fees alone account for an estimated $20 million of the total $70 million increase.

-

Chassis Fees: The costs associated with renting chassis, the wheeled undercarriage for transporting containers, have also surged. Increased demand and limited availability have driven up prices, adding another significant layer of expense. An estimated $15 million of the total increase is attributed to higher chassis fees.

-

Storage Fees: With port congestion delaying unloading and transportation, the need for extended storage at port facilities has increased dramatically. This has led to a substantial rise in storage fees, contributing an estimated $10 million to the $70 million hit.

-

Other Fees: A range of other fees, including terminal handling charges and administrative fees, have also experienced significant increases, adding to the overall financial burden. The remaining $25 million reflects the cumulative impact of these additional charges.

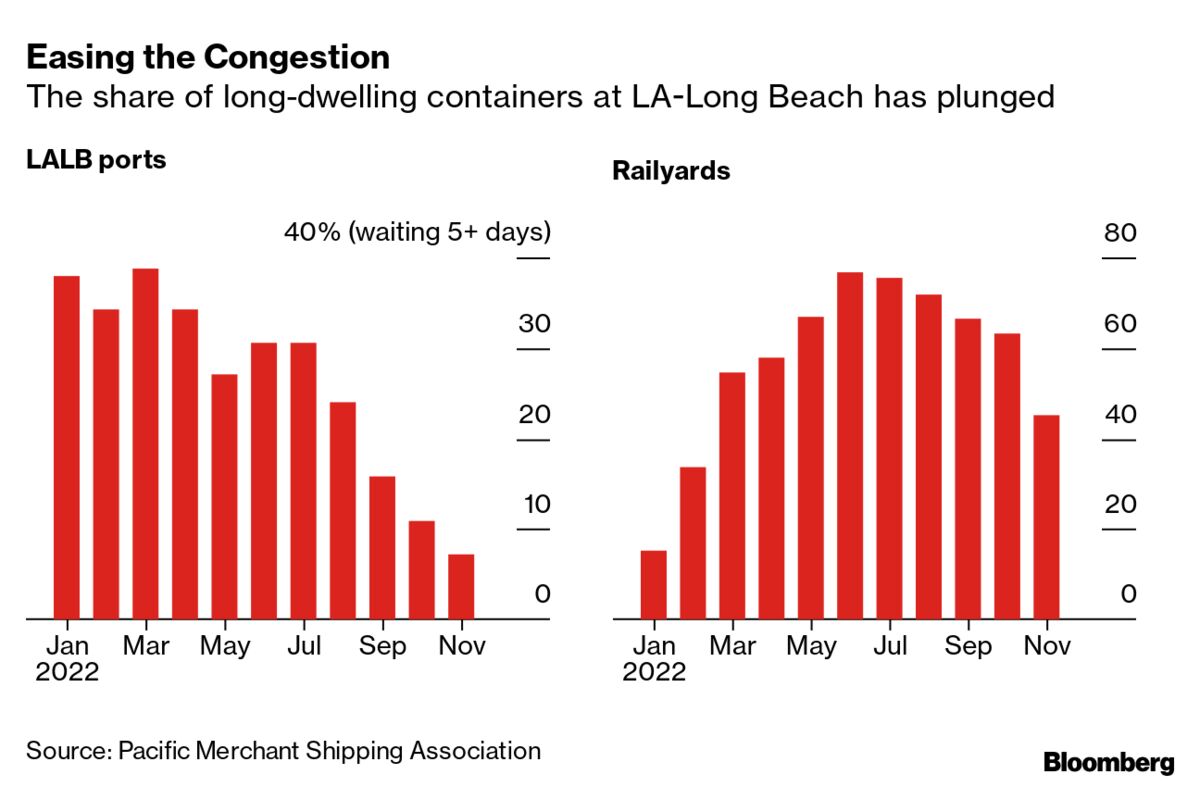

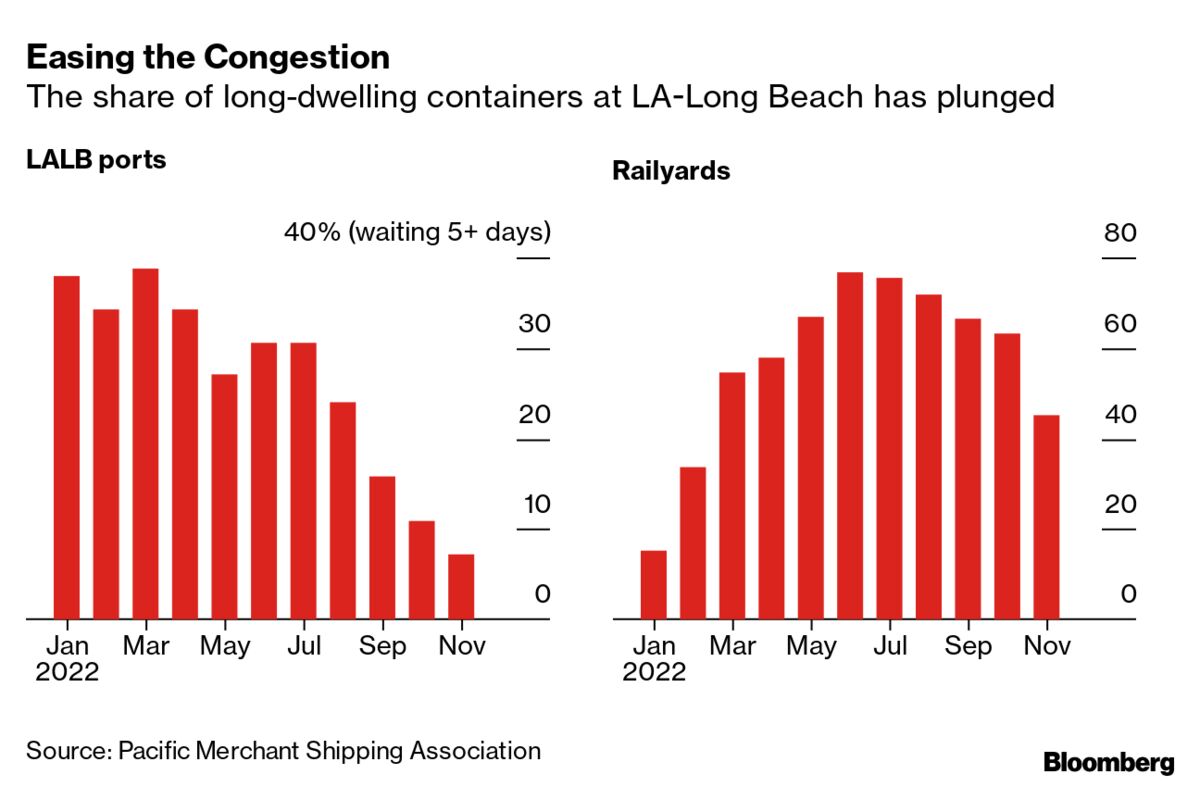

Ports Most Affected: The ports of Los Angeles and Long Beach, major gateways for automotive imports, were particularly hard hit, bearing the brunt of the increased fees and congestion.

- Container dwell fees increased by 25% in the first quarter of 2024 at the Port of Los Angeles.

- Average waiting times for ships increased by 30% at the Port of Long Beach in the same period.

- The impact on individual shipments varies but translates into an average increase of approximately $500 per vehicle.

Underlying Factors Driving the Surge in US Port Fees

Several factors have converged to create this perfect storm of increased US port fees:

-

Port Congestion: A major contributor is severe port congestion. Supply chain bottlenecks stemming from the pandemic, coupled with labor shortages and infrastructure limitations, have led to significant delays in unloading and processing cargo. Ships are forced to wait for extended periods, leading to increased costs.

- Infrastructure Limitations: Outdated infrastructure at many US ports struggles to handle the volume of cargo. A lack of sufficient cranes, storage space, and efficient trucking networks exacerbate congestion.

- Labor Shortages: A shortage of dockworkers and truck drivers further compounds the problem, slowing down the entire process.

- Average Waiting Times: Average waiting times for ships have increased to over 5 days in some ports, leading to significant demurrage and storage charges.

-

Inflation and Rising Fuel Costs: Inflation has driven up the cost of operating ports, including labor, maintenance, and energy. The sharp increase in fuel prices has further added to the expenses associated with port operations.

- Inflation Impact: Inflation rates exceeding 5% significantly impacted port operational costs.

- Fuel Costs: Fuel costs have risen by more than 30% in the past year, directly increasing shipping and handling costs.

-

Government Regulations and Policies: While some regulations aim to improve efficiency and safety, others can inadvertently contribute to congestion and increased costs. Navigating complex regulatory environments adds another layer of complexity and cost for auto carriers.

- Examples of Regulations: Certain environmental regulations, while beneficial in the long run, can temporarily increase operational costs and complexity.

Impact on the Automotive Industry and Consumers

The impact of these rising US port fees extends far beyond the auto carrier experiencing the $70 million hit. The entire automotive industry and, ultimately, consumers will bear the consequences:

-

Increased Vehicle Prices: The higher shipping costs will inevitably lead to increased prices for new vehicles, making cars less affordable for consumers. Estimates suggest an average price increase of between $500 and $1000 per vehicle.

-

Vehicle Availability and Delivery Times: Port congestion and increased shipping costs will lead to delays in vehicle deliveries, making it harder for consumers to get the cars they want in a timely manner. Delivery times could increase by several weeks or even months.

-

Ripple Effects: The disruptions will ripple through the entire automotive supply chain, impacting parts suppliers, dealerships, and related industries. Just-in-time inventory management will be severely challenged.

Strategies for Mitigating the Impact of Rising US Port Fees

Several strategies can be employed to lessen the blow from rising US port fees:

-

Improved Inventory Management: Auto carriers can implement sophisticated inventory management systems to optimize stock levels and reduce the need for lengthy port storage.

-

Optimized Shipping Routes: Exploring alternative shipping routes, including utilizing smaller ports or inland transportation, could reduce reliance on congested major ports.

-

Negotiating with Port Authorities: Direct negotiations with port authorities to secure better pricing and more efficient processing times can help offset some costs.

-

Government Intervention: Increased government investment in port infrastructure upgrades, streamlining of regulations, and addressing labor shortages are crucial to alleviate congestion and control costs.

Government Interventions: Infrastructure investments such as expanding port capacity, modernizing equipment, and improving intermodal transportation links are crucial. Government efforts to address labor shortages and streamline regulatory processes are also key.

Conclusion

The $70 million hit faced by this auto carrier serves as a stark warning of the severe challenges posed by rising US port fees. Port congestion, inflation, and regulatory factors all contribute to this escalating cost burden, impacting the entire automotive industry and ultimately, consumers. Understanding the complexities of US port fees is crucial for navigating the current economic landscape. Stay informed on the latest developments and adapt your strategies to mitigate the impact of these rising costs on your automotive logistics. Learn more about managing the challenges of rising US port fees and protecting your business.

Featured Posts

-

A Conversation With Microsofts Design Chief The Future Of Ai And Human Interaction

Apr 26, 2025

A Conversation With Microsofts Design Chief The Future Of Ai And Human Interaction

Apr 26, 2025 -

I Heart Radio Music Awards 2025 Benson Boones Bold Fashion Choice

Apr 26, 2025

I Heart Radio Music Awards 2025 Benson Boones Bold Fashion Choice

Apr 26, 2025 -

Political Tensions Explode At Town Halls Voters Demand Accountability

Apr 26, 2025

Political Tensions Explode At Town Halls Voters Demand Accountability

Apr 26, 2025 -

Mission Impossible 7 Standee Unveiled At Cinema Con A First Look

Apr 26, 2025

Mission Impossible 7 Standee Unveiled At Cinema Con A First Look

Apr 26, 2025 -

Fugro And Damen Partner To Bolster Royal Netherlands Navy Capabilities

Apr 26, 2025

Fugro And Damen Partner To Bolster Royal Netherlands Navy Capabilities

Apr 26, 2025