Why Nike Sneaker Production Remains A Challenge For Robots

Table of Contents

The Dexterity Dilemma: Handling Diverse Materials and Complex Assembly

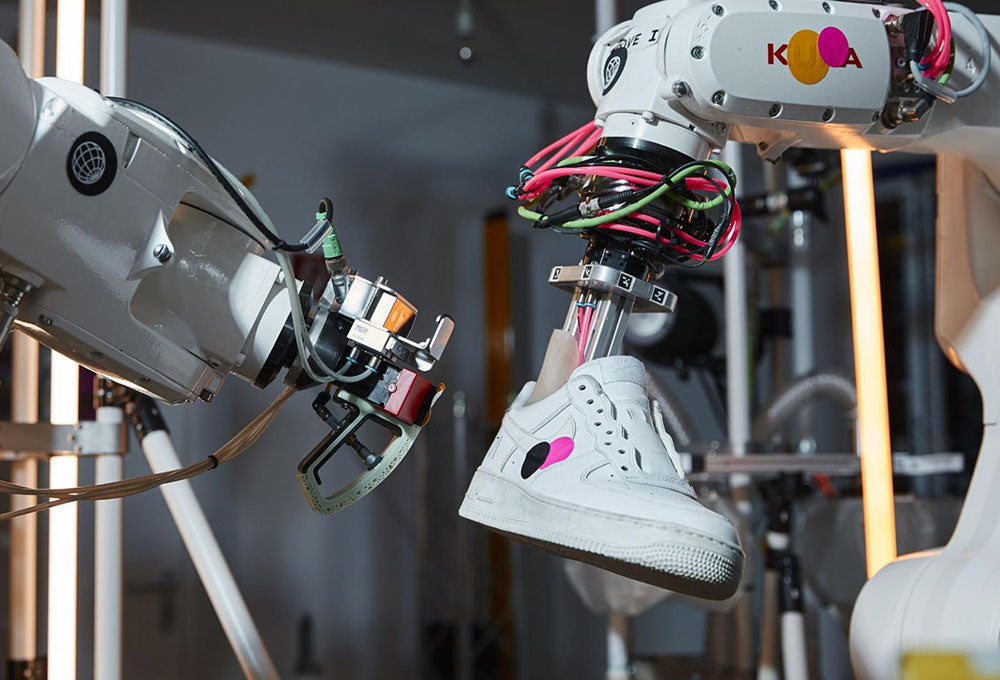

The dexterity required for sneaker production presents a significant challenge for robots. Sneakers aren't made from a single, uniform material; they're a complex assembly of diverse components. This material variety creates significant difficulties for robotic automation.

Material Variability

Robots struggle with the inconsistencies inherent in sneaker materials. Leather, textiles, rubber, and foam all possess varying textures, thicknesses, and flexibilities. This leads to difficulties in consistent gripping and manipulation.

- Difficulty in consistent gripping and manipulation due to material inconsistencies. A robot's gripper needs to adapt to the changing properties of the material it's handling. A grip strong enough for thick leather might crush delicate textiles.

- Need for adaptive grippers and sophisticated sensor systems. Developing robotic grippers capable of adapting to these variations requires advanced sensor technology and sophisticated control algorithms. This adds significant cost and complexity.

- Cost and complexity of developing such advanced robotic systems. The research, development, and manufacturing of these advanced robotic systems are expensive, delaying widespread adoption.

Precise Stitching and Adhesion

The precise stitching and gluing integral to sneaker construction present another significant hurdle. Humans can easily adjust pressure and stitch tension, achieving a consistent and aesthetically pleasing result. Robots struggle to replicate this precision and consistency.

- Challenges in maintaining stitch tension and accuracy across varying materials. Maintaining consistent stitch tension across different materials requires advanced force-feedback sensors and control systems.

- The need for high-resolution vision systems to guide robotic arms. Precise stitching requires robots to "see" where they're stitching, necessitating accurate and high-resolution vision systems.

- The complexities of applying adhesives evenly and precisely. Applying adhesives without creating globs or gaps requires careful control of the dispensing process, which is challenging for robots.

The Adaptability Issue: Handling Variations in Sneaker Designs and Production Lines

Nike's vast array of sneaker styles further complicates robotic automation. Each sneaker model often requires a unique assembly process, adding to the complexity.

Design Diversity

The sheer diversity of Nike sneaker designs poses a significant challenge. Robots need to be reprogrammable, capable of adapting to different models and components with minimal downtime.

- The need for reprogrammable robots capable of adapting to different models and components. Currently, reprogramming robots for each new design is a time-consuming and expensive process.

- The high cost of retooling and reprogramming for each new sneaker design. This high cost limits the economic viability of using robots for smaller production runs of specialized sneaker models.

- The lack of robots that can handle unexpected variations in production. Robots currently lack the adaptability to handle unexpected variations or defects in materials or components.

Production Line Flexibility

Integrating robots into existing, often human-centric, production lines presents integration challenges. Factory layouts and workflows might need significant redesign to accommodate robotic systems.

- The need to redesign factory layouts and workflows to accommodate robots. This can be costly and disruptive to existing operations.

- Integration challenges with existing machinery and software. Seamless integration with existing machinery and software systems is critical but often difficult to achieve.

- The disruption to existing production processes and potential labor concerns. Introducing robots can cause significant disruption to established production processes and raise concerns among the workforce.

The Economic Equation: Cost vs. Efficiency in Robot Nike Sneaker Production

While robotic automation offers potential efficiency gains, the significant upfront investment required presents a significant barrier.

High Initial Investment

The costs associated with purchasing, implementing, and maintaining robotic systems for sneaker production are substantial.

- The cost of advanced robotic arms, vision systems, and software. These advanced technologies are expensive to acquire and maintain.

- The cost of training personnel to operate and maintain the robots. Specialized training is necessary, adding to the overall cost.

- The cost of potential downtime due to malfunctions or reprogramming. Malfunctions or the need for reprogramming can lead to costly production downtime.

Return on Investment (ROI)

Achieving a positive return on investment (ROI) on robotic systems in sneaker manufacturing is challenging, particularly considering the high labor costs in many regions.

- The difficulty in justifying the high upfront costs compared to the potential efficiency gains. The ROI needs to be carefully evaluated against the potential savings in labor costs.

- The need for significant volume to amortize the costs of robotic systems. High production volumes are needed to justify the significant investment in robotic technology.

- The ongoing challenges of maintaining and upgrading robotic equipment. Robots require ongoing maintenance and upgrades, adding to the overall cost of ownership.

Conclusion

The challenges of robot Nike sneaker production are multifaceted. Dexterity in handling diverse materials, adaptability to changing designs and production lines, and the high economic investment required all present significant hurdles. While robotic automation holds immense promise, significant technological advancements are needed before it becomes a widespread reality in this intricate manufacturing process. To stay updated on this dynamic field, follow industry news and research into advancements in robotics and manufacturing technology. The future of Nike robot sneaker production, and indeed robotic footwear manufacturing as a whole, depends on overcoming these challenges.

Featured Posts

-

Assessing Pope Franciss Pontificate The Conclaves Verdict

Apr 22, 2025

Assessing Pope Franciss Pontificate The Conclaves Verdict

Apr 22, 2025 -

Hollywood Strike Actors Join Writers Bringing Production To A Halt

Apr 22, 2025

Hollywood Strike Actors Join Writers Bringing Production To A Halt

Apr 22, 2025 -

Chat Gpt Creator Open Ai Under Federal Trade Commission Investigation

Apr 22, 2025

Chat Gpt Creator Open Ai Under Federal Trade Commission Investigation

Apr 22, 2025 -

Understanding Papal Conclaves Secrecy Tradition And The Election Of A Pope

Apr 22, 2025

Understanding Papal Conclaves Secrecy Tradition And The Election Of A Pope

Apr 22, 2025 -

Closer Security Cooperation Between China And Indonesia

Apr 22, 2025

Closer Security Cooperation Between China And Indonesia

Apr 22, 2025