Why Robots Still Can't Replace Human Labor In Nike Sneaker Manufacturing

Table of Contents

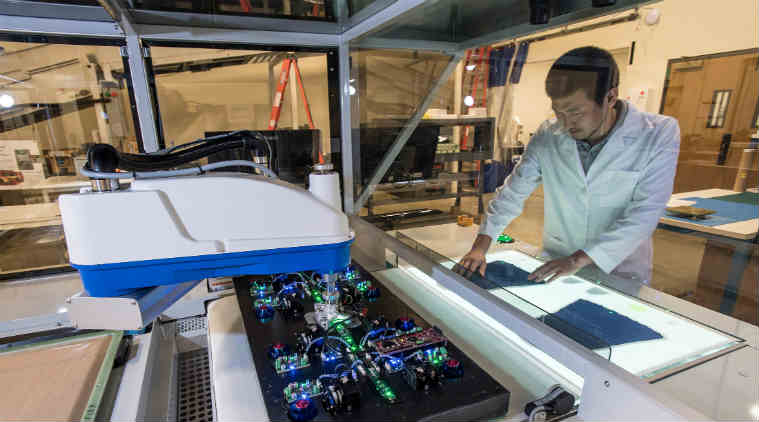

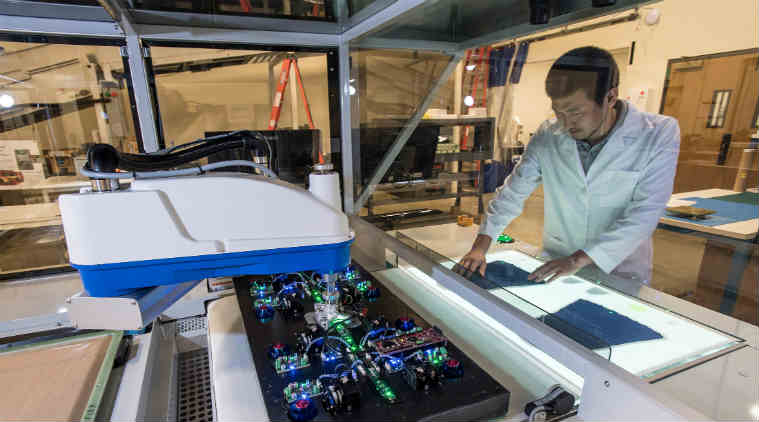

The Complexity of Dexterous Manipulation and Fine Motor Skills

The intricate process of crafting a Nike sneaker involves a surprising level of dexterity and precision. The question of robots replacing human labor in this context is heavily influenced by the inherent challenges in replicating human fine motor skills.

Challenges in Handling Varied Materials

Nike sneakers utilize a diverse range of materials – supple leather, durable suede, breathable textiles, and reinforced synthetics. The precise manipulation and assembly of these varied textures and thicknesses present a significant hurdle for current robotic technology.

- Intricate Stitching: Robots struggle with the precise control needed for consistent, high-quality stitching, particularly on curved surfaces or with delicate materials.

- Gluing Delicate Components: Applying the correct amount of adhesive to small, delicate components requires a level of tactile sensitivity that robots currently lack.

- Precise Placement of Components: Aligning and securing various parts with the accuracy and speed needed for mass production is challenging for robotic systems.

Human hands possess an unmatched level of dexterity and sensitivity, allowing for adjustments and corrections that are impossible for even the most advanced robotic grippers. Current robotic manipulators lack the adaptability to handle the subtle variations in material thickness and texture.

Adaptability to Unpredictable Variations

Manufacturing processes are rarely perfectly predictable. Material inconsistencies, minor defects, and unforeseen issues require human judgment and adaptation.

- Correcting Flaws: Human workers can quickly identify and correct flaws in materials or assembly, ensuring quality control.

- Adapting to Material Defects: Imperfections in materials often require flexible problem-solving, something robots currently lack.

- Ensuring Consistent Quality: Maintaining consistent quality across a high-volume production line necessitates human oversight and intervention.

Robust AI systems capable of real-time adaptation to such unpredictable variations are still under development. The ability to make split-second decisions and adjust techniques based on unexpected circumstances remains a uniquely human skill.

The High Costs and Limited Return on Investment of Full Automation

The transition to complete automation in Nike sneaker manufacturing presents significant financial barriers. The cost implications far outweigh the potential short-term benefits.

Initial Investment Costs

Implementing fully automated systems necessitates substantial upfront investments.

- Robotic Systems: The cost of purchasing and installing advanced robotic systems is extremely high.

- Specialized Software: Programming and integrating complex software for robotic control requires skilled technicians and considerable time.

- Infrastructure Upgrades: Factory modifications to accommodate robotic systems add to the overall expense.

These costs must be weighed against the cost of human labor, making full automation financially unfeasible for many aspects of the production process.

Maintenance and Repair Costs

Automated systems require ongoing maintenance and are susceptible to malfunctions.

- System Failures: Robotic systems can malfunction, leading to production delays and lost revenue.

- Specialized Technicians: Maintaining and repairing sophisticated robotic equipment necessitates specialized technicians, increasing operational costs.

- Downtime: Repairing malfunctioning robots can cause significant downtime, halting production and impacting overall efficiency.

The long-term costs of maintaining a fully automated system may exceed the costs associated with employing and training human workers, especially given the potential for unpredictable downtime.

The Importance of Human Creativity and Innovation in Design and Production

Human ingenuity remains a crucial element in the design and production of Nike sneakers. The complexities of design and the need for rapid problem-solving cannot be replicated by current technology.

Design and Customization

Human designers are essential for developing innovative shoe designs that meet evolving consumer trends and demands.

- Bespoke Designs: The creation of bespoke sneakers and limited-edition designs requires creative input from human designers.

- Customized Features: Integrating specific customer requests and personalized features often involves human craftsmanship and design.

- Aesthetic Appeal: The artistic and aesthetic aspects of shoe design rely heavily on human creativity and intuition.

Artificial intelligence struggles to match the originality, aesthetic sensitivity, and market understanding inherent in human design.

Problem Solving and Adaptability

Human workers demonstrate exceptional problem-solving skills and adaptability in unpredictable situations.

- Unforeseen Challenges: Unexpected problems during production often require quick, intuitive solutions from experienced workers.

- Process Improvement: Human workers can identify inefficiencies and suggest improvements to production processes.

- Troubleshooting: Dealing with unforeseen technical difficulties or equipment malfunctions typically necessitates human expertise.

While AI is improving, its ability to handle unexpected issues and adapt to changing circumstances remains limited compared to human adaptability.

Conclusion

In summary, while robotics and automation play a growing role in Nike's sneaker manufacturing, the complete replacement of human labor is currently impractical. The inherent complexities of handling diverse materials, the high costs and maintenance of fully automated systems, and the crucial role of human creativity and problem-solving all point to the continued importance of human workers. The future of Nike's production, and indeed the broader footwear industry, likely lies in a collaborative model leveraging the strengths of both human workers and robotic systems. Further exploration into the role of robots in Nike's production and the future of human labor in sneaker manufacturing is crucial for understanding the evolving landscape of this dynamic industry.

Featured Posts

-

Cassidy Hutchinson Plans Memoir Detailing January 6th Testimony

Apr 22, 2025

Cassidy Hutchinson Plans Memoir Detailing January 6th Testimony

Apr 22, 2025 -

1 Billion Cut Trump Administration Targets Harvard Funding Amidst Growing Tensions

Apr 22, 2025

1 Billion Cut Trump Administration Targets Harvard Funding Amidst Growing Tensions

Apr 22, 2025 -

The Future Of Robotics In Nike Sneaker Manufacturing

Apr 22, 2025

The Future Of Robotics In Nike Sneaker Manufacturing

Apr 22, 2025 -

Trade War Concerns Weigh On Markets Dow Futures Dollar Dip Live Updates

Apr 22, 2025

Trade War Concerns Weigh On Markets Dow Futures Dollar Dip Live Updates

Apr 22, 2025 -

Three Years Of Data Breaches Cost T Mobile A 16 Million Fine

Apr 22, 2025

Three Years Of Data Breaches Cost T Mobile A 16 Million Fine

Apr 22, 2025