Advanced Techniques For Automated Visual Inspection Of Lyophilized Vials

Table of Contents

Image Acquisition and Preprocessing for Optimal Inspection

High-quality image acquisition forms the bedrock of successful automated visual inspection. The clarity and accuracy of the captured images directly influence the effectiveness of defect detection. Achieving this requires careful consideration of several factors, including appropriate lighting techniques and robust camera systems.

Key aspects of optimal image acquisition include:

- High-resolution imaging: Utilizing high-resolution cameras ensures the capture of fine details crucial for identifying even minor defects in lyophilized vials. Higher resolution translates to improved accuracy in defect detection and classification.

- Lighting techniques: The choice of lighting is paramount. Coaxial lighting, which illuminates the vial from directly above, minimizes shadows and provides uniform illumination. Diffused lighting can also be beneficial to reduce glare and enhance contrast.

- Specialized cameras: Employing cameras with features tailored for pharmaceutical inspection, such as high sensitivity and low noise, further enhances image quality.

Effective image preprocessing further refines the images, preparing them for accurate defect detection. Common preprocessing techniques include:

- Noise reduction algorithms: Algorithms like median filtering effectively remove random noise from the images, improving clarity and preventing false positives during defect detection.

- Image enhancement techniques: Techniques such as contrast adjustment and sharpening improve the visibility of defects by enhancing the differences between the vial's surface and any anomalies.

- Background correction methods: Removing or minimizing the background variations helps isolate the vial itself, focusing the analysis solely on the vial's contents and surface.

- Color space transformations: Converting images into different color spaces (e.g., HSV) can help enhance the contrast of specific defects, making them easier to identify.

Example: By implementing advanced noise reduction and contrast enhancement techniques, a pharmaceutical company reduced false positives by 15%, leading to a significant increase in inspection throughput and a decrease in wasted resources.

Advanced Algorithm Development for Defect Detection in Lyophilized Vials

The core of automated visual inspection lies in the algorithms used to detect defects. Advanced algorithms, particularly those leveraging machine learning and deep learning, are transforming defect detection in lyophilized vials.

- Machine learning and deep learning: These techniques excel at pattern recognition, enabling the system to learn from a vast dataset of images and identify various defects with high accuracy.

- Training data generation and augmentation: Creating a large and diverse dataset is vital for training these algorithms. Data augmentation techniques, such as image rotation and scaling, can artificially increase the size of the training dataset, further improving model robustness.

- Convolutional Neural Networks (CNNs): CNNs are particularly well-suited for image analysis, effectively identifying complex patterns and features associated with defects like cracks, particulate matter, and insufficient fill.

- Specific algorithms for defect detection: Specialized algorithms can be designed to focus on specific types of defects. For instance, a dedicated algorithm can be developed for crack detection, utilizing edge detection and image segmentation techniques. Similarly, other algorithms can be optimized for particle detection and fill level measurement.

- Handling variations: Robust algorithms must account for variations in vial shape, size, and fill levels to maintain accuracy across different batches and manufacturing processes.

Example: One pharmaceutical manufacturer successfully implemented a deep learning-based algorithm that reduced the rate of defective vials escaping detection by 20% compared to their previous manual inspection system, significantly improving product quality and minimizing customer complaints.

Integrating Automated Visual Inspection into Existing Production Lines

Successfully integrating automated visual inspection systems into existing production lines requires careful planning and execution. This involves several key considerations:

- System integration and compatibility: The system needs to seamlessly integrate with existing equipment, minimizing disruption to the production workflow. This may involve modifications to existing conveyor systems and data transfer protocols.

- Data management and reporting: The system should provide comprehensive data management and reporting capabilities, generating detailed reports on defect rates, types of defects identified, and other relevant metrics. This information is crucial for continuous improvement and quality assurance.

- Validation and qualification: To ensure compliance with Good Manufacturing Practice (GMP) regulations, the automated inspection system must undergo rigorous validation and qualification processes. This confirms the accuracy and reliability of the system.

- Minimizing downtime and maximizing throughput: The implementation should minimize downtime during integration and ensure that the system operates efficiently, maximizing production throughput without compromising accuracy.

Example: A leading pharmaceutical company integrated an automated visual inspection system into its lyophilized vial production line, resulting in a 30% increase in throughput and a 15% reduction in labor costs within six months. The system also enabled the company to meet stricter regulatory compliance requirements with ease.

Benefits of Automated Visual Inspection of Lyophilized Vials

The advantages of implementing automated visual inspection systems for lyophilized vials are numerous and significant:

- Increased efficiency: Automation drastically reduces inspection time, enabling higher production throughput.

- Improved accuracy: Automated systems offer superior accuracy compared to manual inspection, minimizing human error and false positives.

- Reduced labor costs: Automation reduces the need for manual labor, leading to significant cost savings.

- Enhanced product quality: By detecting and rejecting defective vials, automated systems guarantee higher product quality and consistency.

- Regulatory compliance: Automated systems aid in meeting stringent regulatory requirements, ensuring compliance with GMP standards.

Conclusion

Advanced techniques in automated visual inspection are transforming the quality control processes for lyophilized vials in the pharmaceutical industry. By combining high-resolution imaging, sophisticated algorithms like deep learning, and effective system integration, manufacturers can achieve significant improvements in accuracy, efficiency, and regulatory compliance. The benefits—including reduced costs, enhanced product quality, and increased throughput—make the investment in advanced automated visual inspection systems a crucial step towards maintaining the highest standards in pharmaceutical manufacturing. Learn more about improving your lyophilized vial quality control with advanced automated visual inspection techniques. Contact us today to discuss your automated visual inspection needs and how we can help optimize your production processes.

Featured Posts

-

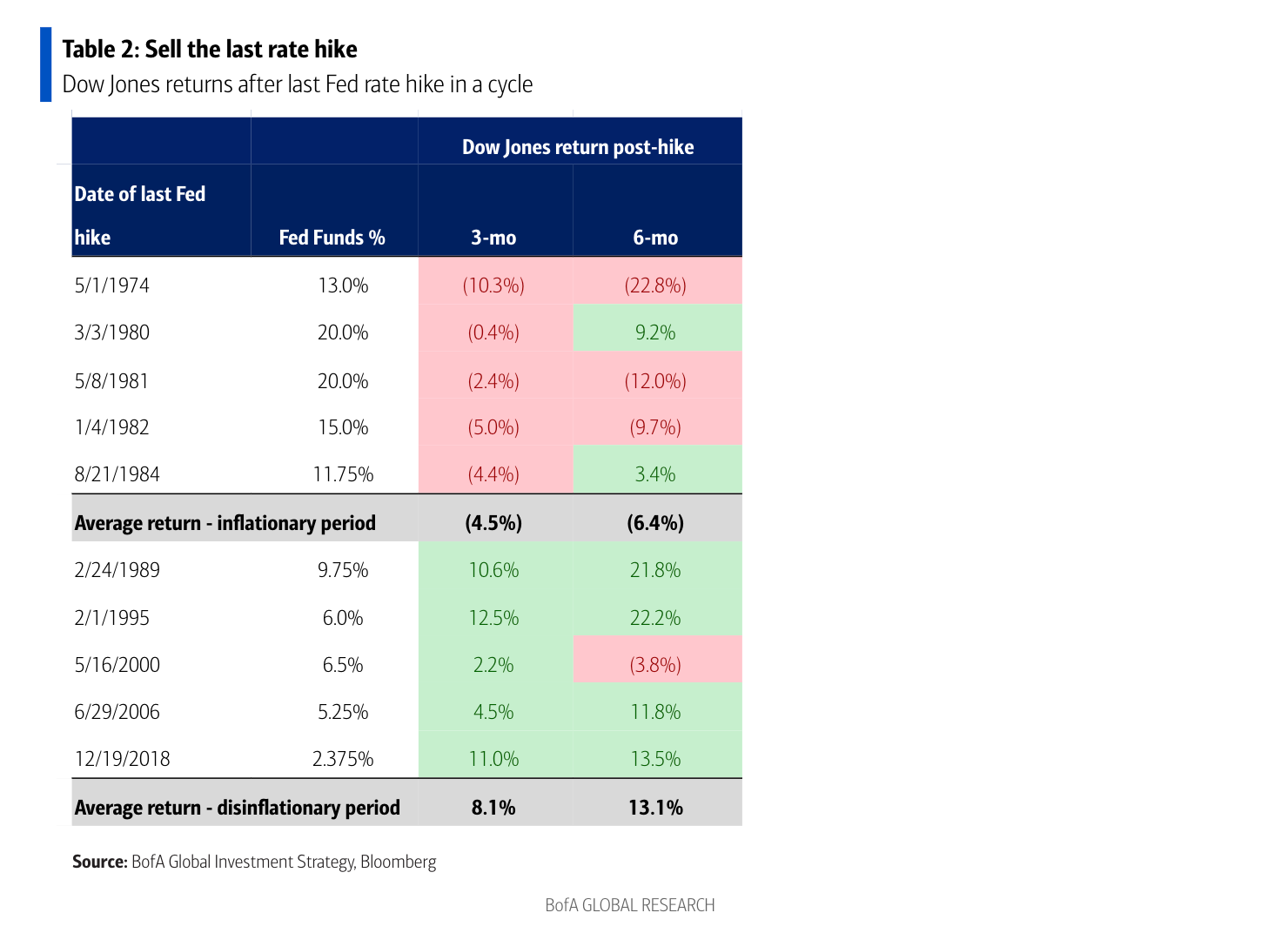

Are High Stock Market Valuations A Concern Bof As Analysis

May 11, 2025

Are High Stock Market Valuations A Concern Bof As Analysis

May 11, 2025 -

Cardinals In The Running For The Papacy A Look At The Contenders

May 11, 2025

Cardinals In The Running For The Papacy A Look At The Contenders

May 11, 2025 -

Adam Sandler A Symbol Of Unity In Tumultuous Times

May 11, 2025

Adam Sandler A Symbol Of Unity In Tumultuous Times

May 11, 2025 -

Las Vegas John Wick Experience Embrace Your Inner Baba Yaga

May 11, 2025

Las Vegas John Wick Experience Embrace Your Inner Baba Yaga

May 11, 2025 -

Muellers Bayern Exit Welke Competitie Lokt Hem

May 11, 2025

Muellers Bayern Exit Welke Competitie Lokt Hem

May 11, 2025