BYD: Leading The Way In EV Battery Production - A Case Study Addendum

Table of Contents

BYD's Blade Battery Technology: A Game Changer

BYD's Blade Battery technology represents a significant leap forward in EV battery technology. This innovative approach has redefined what's possible in terms of energy density, safety, and manufacturing efficiency.

Superior Energy Density and Safety

Unlike traditional cylindrical or prismatic cells, BYD's Blade Battery boasts a unique design. Its elongated, blade-like form factor allows for higher energy density within the same battery pack volume. This translates to several key advantages:

- Increased range per charge: Drivers benefit from significantly longer driving distances on a single charge, addressing a major concern for EV adoption.

- Improved crash safety ratings: The Blade Battery's robust design enhances structural integrity, contributing to improved vehicle safety in collisions.

- Smaller battery packs for same energy capacity: The increased energy density allows for smaller and lighter battery packs, optimizing vehicle design and performance.

The battery's unique internal composition and structure also contribute to enhanced safety. The design minimizes the risk of thermal runaway, a critical safety concern with traditional lithium-ion batteries.

Scalability and Manufacturing Efficiency

BYD's success isn't solely about innovative design; it's also about efficient mass production. Their advanced manufacturing processes and high levels of automation allow for the cost-effective production of Blade Batteries at a massive scale. This translates into:

- High production volume: BYD can meet the growing global demand for EV batteries, ensuring sufficient supply for its own vehicles and potentially for third-party manufacturers.

- Reduced manufacturing costs: Efficient processes contribute to lower production costs, making EVs more affordable and accessible.

- Consistent quality control: Automation ensures consistent quality and performance across all Blade Batteries.

BYD's partnerships with material suppliers and its investments in advanced manufacturing facilities further strengthen its production capabilities.

Vertical Integration: Controlling the Entire Supply Chain

BYD's success is further amplified by its vertically integrated approach to battery production. This strategy allows them to control every step of the process, from raw material sourcing to finished product assembly.

From Raw Materials to Finished Product

BYD's vertical integration extends across various stages of battery production:

- Mining: Securing access to critical raw materials, such as lithium and cobalt, is crucial. BYD’s strategic investments in mining operations ensure a reliable supply.

- Processing: BYD refines and processes raw materials, ensuring consistent quality and reducing reliance on external suppliers.

- Cell assembly: BYD controls the entire cell assembly process, from component manufacturing to final battery pack integration.

The benefits are numerous: reduced reliance on third-party suppliers, tighter quality control, and faster innovation cycles. This allows BYD to quickly adapt to market demands and technological advancements.

Securing Key Resources and Reducing Risks

Vertical integration provides significant advantages in mitigating supply chain risks:

- Reduced vulnerability to price fluctuations: Controlling the supply chain minimizes the impact of fluctuating raw material prices.

- Increased supply chain security: BYD has less exposure to potential disruptions from external factors such as geopolitical instability.

- Minimized geopolitical risks: Direct control of resources helps circumvent potential trade barriers or supply constraints.

BYD's proactive approach to resource management and its strategic investments have enabled them to navigate global supply chain challenges effectively.

Impact on the Global EV Market and Future Outlook

BYD's innovative approach to BYD EV battery production is having a profound impact on the global EV market.

Competition and Market Share

BYD is rapidly gaining market share in the EV battery sector, challenging established players and setting new benchmarks for the industry. This is due to a combination of factors:

- Increasing market dominance: BYD's growing production capacity and its competitive pricing strategies are driving its market penetration.

- Technological leadership: Blade Battery technology and other innovations are propelling BYD to the forefront of technological advancement.

- Competitive pricing strategies: BYD's efficient manufacturing processes allow for competitive pricing, making its batteries attractive to various EV manufacturers.

Market data shows a significant increase in BYD's market share year-on-year, underscoring its rapid ascent in this competitive landscape.

Innovation and Future Technologies

BYD's commitment to research and development ensures its continued leadership in the EV battery sector. The company is exploring numerous advancements beyond Blade Batteries:

- Solid-state batteries: BYD is actively investing in solid-state battery technology, promising even higher energy density and improved safety features.

- Next-generation cell chemistries: Research into alternative chemistries could further enhance battery performance and sustainability.

- Improved battery management systems: Sophisticated battery management systems are critical for optimizing battery lifespan and performance.

BYD's ongoing commitment to innovation suggests a future of even more advanced battery technology, shaping the future of electric mobility.

Conclusion

BYD's innovative approach to EV battery production, particularly its Blade Battery technology and vertically integrated supply chain, has propelled it to the forefront of the global EV revolution. Their technological advancements, manufacturing efficiency, and strategic control over resources have positioned them for continued success in a rapidly evolving market. The future of EV battery technology is bright, and BYD’s commitment to innovation ensures they will remain a key player in shaping that future. To learn more about the latest advancements in BYD EV battery production, continue exploring our resources and stay updated on the latest industry news.

Featured Posts

-

Scarlett Johansson Challenges Open Ai On Ai Voice Rights And Boundaries

May 13, 2025

Scarlett Johansson Challenges Open Ai On Ai Voice Rights And Boundaries

May 13, 2025 -

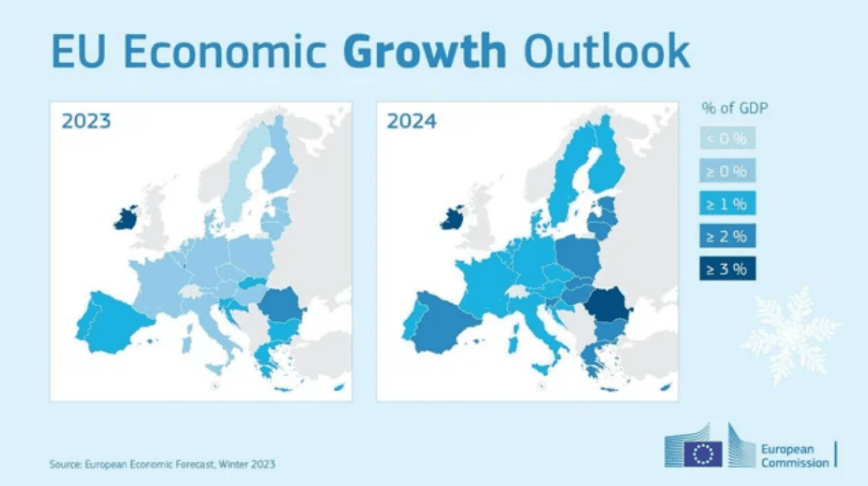

The Return Of Trump Tariffs A European Economic Forecast

May 13, 2025

The Return Of Trump Tariffs A European Economic Forecast

May 13, 2025 -

Find The Doom Dark Ages Xbox Controller On Sale At Amazon

May 13, 2025

Find The Doom Dark Ages Xbox Controller On Sale At Amazon

May 13, 2025 -

Hostage Situation A Fathers Inspiring Message

May 13, 2025

Hostage Situation A Fathers Inspiring Message

May 13, 2025 -

Understanding Life Cycles The Role Of Campus Farm Animals In Student Learning

May 13, 2025

Understanding Life Cycles The Role Of Campus Farm Animals In Student Learning

May 13, 2025