Chinese Plastics Makers Face Iran Supply Disruption Amid US Sanctions

Table of Contents

The Scale of the Problem: Iran's Role in Chinese Plastics Supply

China's plastics industry has, for years, relied heavily on Iran for essential petrochemical feedstocks. This dependence on Iranian plastics exports is a significant factor driving the current crisis.

Dependence on Iranian Petrochemicals

The extent of China's reliance on Iran for raw materials like polyethylene (PE) and polypropylene (PP) is substantial. While precise figures are difficult to obtain due to the opaque nature of some trade routes, estimates suggest a significant percentage of China's imports of these key plastics building blocks originate from Iran. This is due, in part, to the cost-effectiveness of Iranian supplies, making them highly attractive to Chinese manufacturers.

- Specific Petrochemical Products: China imports substantial quantities of linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), and polypropylene (PP) from Iran.

- Major Chinese Companies Involved: Numerous large and small Chinese plastics processing companies are affected, many operating within the packaging, automotive, and construction sectors. Specific company names are often withheld due to the sensitivity of the geopolitical situation.

- Cost-Effectiveness: Iranian petrochemicals have historically been competitively priced, offering a significant cost advantage over other suppliers, increasing China's reliance on this supply source.

Navigating US Sanctions: Challenges for Chinese Businesses

The imposition of US sanctions on Iran presents significant obstacles for Chinese companies involved in the plastics industry. These sanctions complicate trade, creating compliance and legal risks.

Compliance and Legal Risks

Complying with US sanctions while maintaining business relationships with Iranian suppliers is incredibly complex. The extraterritorial reach of these sanctions means that even transactions not directly involving US entities can be subject to penalties.

- Sanctions Violations and Consequences: Violations can lead to significant financial penalties, asset freezes, and even criminal prosecution for both Chinese companies and individuals involved.

- Legal Hurdles: Chinese companies face legal complexities in navigating international trade law and the intricacies of US sanctions regulations. This requires specialized legal expertise, increasing costs and creating uncertainty.

- Role of International Banking and Trade Finance: The involvement of US banks or financial institutions in any transaction, however indirect, can trigger sanctions implications, making financing imports from Iran incredibly difficult.

Increased Costs and Supply Chain Instability

The disruption of Iranian supplies has led to increased costs and significant instability in the Chinese plastics supply chain.

- Price Fluctuations: The reduced supply of Iranian petrochemicals has caused price volatility, making it difficult for Chinese companies to accurately forecast costs and plan production.

- Transportation Challenges: Finding alternative transportation routes and securing reliable shipping can add considerable expense and lead to delays.

- Production Delays: Shortages of raw materials can halt or significantly slow down production, impacting the timely delivery of finished goods and potentially affecting contracts.

- Impact on Pricing and Availability: These challenges have contributed to increased prices and reduced availability of finished plastic goods in China and globally, creating ripple effects throughout related industries.

Alternative Sourcing Strategies and Adaptation

Faced with this disruption, Chinese plastics manufacturers are actively exploring alternative sourcing strategies and adopting innovative solutions to ensure business continuity.

Exploring New Suppliers

Chinese companies are actively seeking alternative sources of raw materials, diversifying their supply chains to reduce dependence on Iran.

- Alternative Suppliers: Several Middle Eastern countries, Southeast Asian nations, and other regions are being explored as potential replacements for Iranian petrochemicals. However, securing reliable supply and comparable quality at competitive prices presents considerable challenges.

- Challenges and Opportunities: Each alternative supplier presents unique challenges related to logistics, quality control, and political stability. Opportunities exist to forge new partnerships and create more resilient supply chains.

- Logistical Aspects, Quality Control, and Pricing: These factors are crucial considerations when evaluating alternative suppliers. Ensuring quality control and competitive pricing can be difficult, especially when dealing with unfamiliar suppliers and markets.

Technological Innovation and Waste Reduction

Technological advancements and a focus on sustainability are playing a key role in mitigating the impact of the supply disruption.

- New Technologies in Plastics Production and Recycling: Innovations in plastics production, such as advanced recycling techniques and the development of bio-based plastics, offer alternatives to traditional petrochemical-based polymers.

- Government Policies Promoting Sustainability: The Chinese government is increasingly promoting a circular economy and encouraging investment in recycling and waste reduction initiatives.

- Role of Circular Economy Initiatives: Efforts to improve recycling infrastructure and promote the reuse of plastic waste can reduce reliance on virgin materials and create a more sustainable industry.

Conclusion

The disruption of Iranian plastics exports due to US sanctions presents a significant challenge to Chinese plastics makers. The scale of the problem, the reliance on Iranian petrochemicals, and the difficulties in navigating sanctions have created a crisis. However, proactive strategies like exploring alternative sourcing, investing in technological innovation, and embracing sustainable solutions are crucial for mitigating the long-term effects. The impact extends beyond China, influencing global plastics markets and consumer goods pricing.

Call to Action: The ongoing impact of US sanctions on Chinese plastics makers underscores the urgent need for robust supply chain diversification and a commitment to sustainable plastics solutions. Staying informed on the evolving geopolitical landscape and strategically investing in innovative solutions is vital. Further research into alternative sourcing of Iranian petrochemicals is crucial for the future resilience of the Chinese plastics industry and the global plastics market.

Featured Posts

-

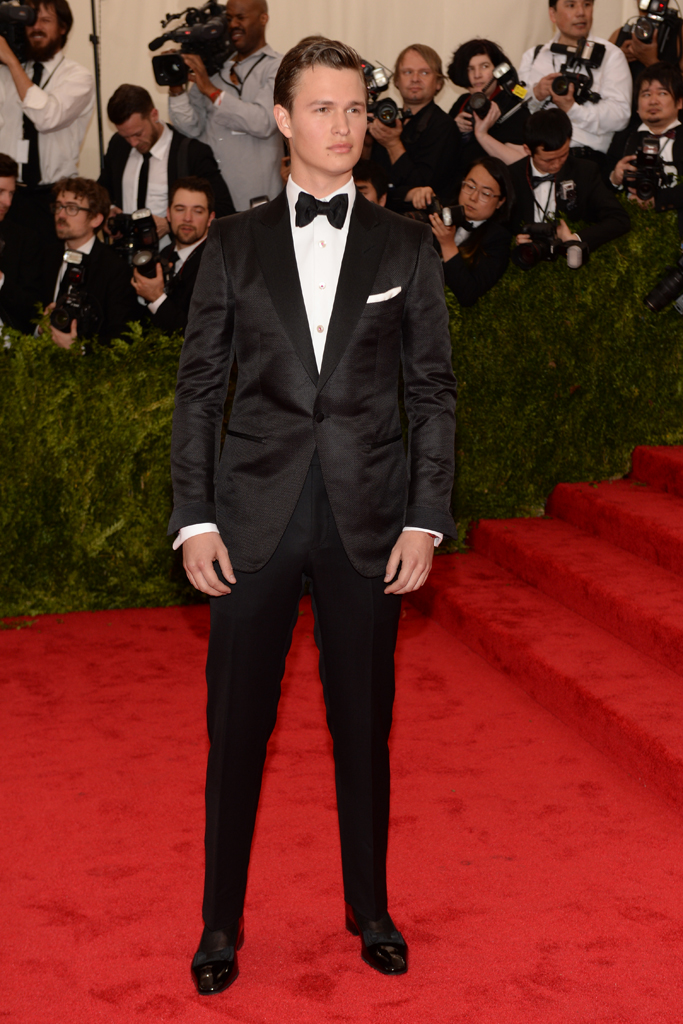

A List Celebs Dazzle At The Met Gala Red Carpet

May 07, 2025

A List Celebs Dazzle At The Met Gala Red Carpet

May 07, 2025 -

Unveiling Cloudzones Spring 2025 Collection Zendayas Zone Dreamer Campaign

May 07, 2025

Unveiling Cloudzones Spring 2025 Collection Zendayas Zone Dreamer Campaign

May 07, 2025 -

Where To Watch The March 3rd Warriors Vs Hornets Game Tv Listings And Streaming

May 07, 2025

Where To Watch The March 3rd Warriors Vs Hornets Game Tv Listings And Streaming

May 07, 2025 -

The Last Of Us Season 2 Episode 4 A Week Long Filming Process

May 07, 2025

The Last Of Us Season 2 Episode 4 A Week Long Filming Process

May 07, 2025 -

A Szineszno Aki Inspiralta Jenna Ortegat

May 07, 2025

A Szineszno Aki Inspiralta Jenna Ortegat

May 07, 2025

Latest Posts

-

Xrp Recovery Stalled Derivatives Market Analysis

May 08, 2025

Xrp Recovery Stalled Derivatives Market Analysis

May 08, 2025 -

The Future Of Xrp Etf Potential Sec Decisions And Market Predictions

May 08, 2025

The Future Of Xrp Etf Potential Sec Decisions And Market Predictions

May 08, 2025 -

Xrp Price Recovery Derivatives Market Slowdown

May 08, 2025

Xrp Price Recovery Derivatives Market Slowdown

May 08, 2025 -

Ripples Xrp Navigating The Sec Landscape And The Path To Etf Approval

May 08, 2025

Ripples Xrp Navigating The Sec Landscape And The Path To Etf Approval

May 08, 2025 -

Xrp On The Brink Analyzing The Impact Of Potential Etfs And Sec Actions

May 08, 2025

Xrp On The Brink Analyzing The Impact Of Potential Etfs And Sec Actions

May 08, 2025