Navigating Tariff Turbulence: ABI Research's Analysis Of The Tech Sector's Trade War Experience

Table of Contents

The Impact of Tariffs on Hardware Manufacturing

Increased tariffs have dealt a significant blow to hardware manufacturers, creating a ripple effect throughout the industry. The primary impacts stem from rising component costs and resulting supply chain disruptions.

Rising Component Costs

Increased tariffs on imported components, such as semiconductors, displays, and memory chips, directly increase manufacturing costs for electronics companies. This leads to a domino effect:

- Increased production expenses leading to higher end-user prices: Consumers ultimately bear the brunt of increased tariffs through higher prices for electronics. This can dampen demand and impact market share.

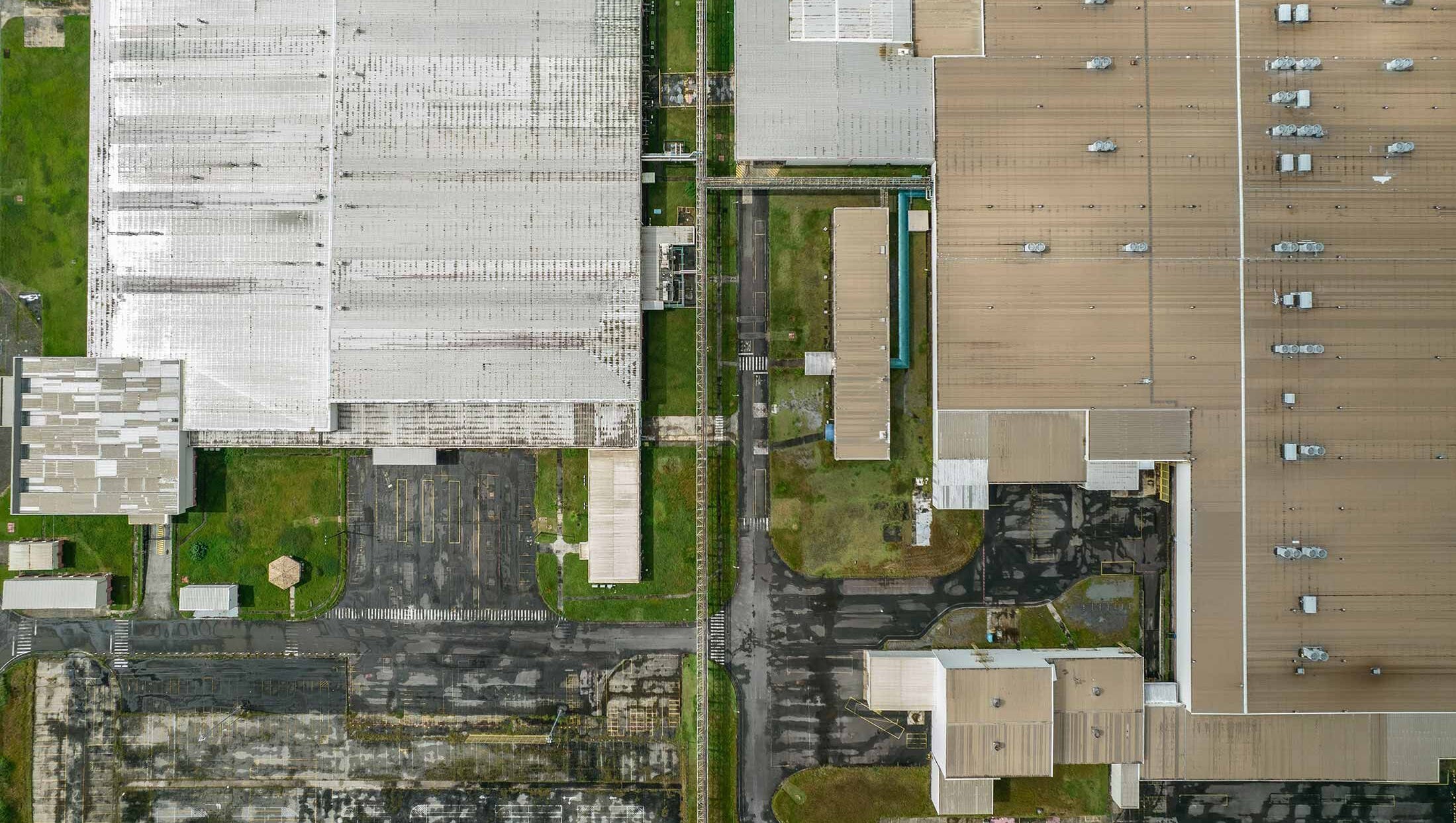

- Shifting manufacturing locations to avoid tariffs: Companies are actively seeking alternative manufacturing locations in countries with more favorable trade agreements to reduce tariff burdens. This involves significant investment and logistical challenges.

- Exploration of alternative component suppliers: Diversifying the sourcing of components is critical. This requires thorough due diligence, potentially impacting timelines and increasing complexity.

Supply Chain Disruptions

Tariffs introduce significant uncertainty and instability into global supply chains, leading to various disruptions:

- Difficulty in forecasting demand due to tariff-related uncertainty: The unpredictable nature of tariff changes makes it extremely difficult for companies to accurately predict future demand.

- Increased lead times for procuring components: Navigating the complexities of tariffs adds significant delays to the procurement process, potentially impacting production schedules.

- Necessity for more robust and diversified supply chain strategies: Companies must invest in more resilient and adaptable supply chains that can withstand future tariff shocks. This involves diversification of suppliers, geographical locations, and transportation methods.

The Effect on Software and Services

While less directly impacted than hardware, the software and services sector is not immune to the effects of tariff turbulence. The impact is felt primarily through infrastructure costs and potential regulatory changes.

Cloud Computing and Data Centers

Cloud computing providers are indirectly affected by tariffs on infrastructure components needed for data center construction and maintenance:

- Increased costs for data center construction and maintenance: Tariffs on imported servers, networking equipment, and other hardware raise the cost of building and operating data centers.

- Potential for higher cloud service pricing: These increased costs may be passed on to consumers through higher cloud service pricing, potentially impacting competitiveness.

- Strategic investments in regional data centers to mitigate tariff impact: To lessen the impact, cloud providers are strategically investing in data centers within regions to minimize reliance on imported components.

Software Licensing and Intellectual Property

The impact on software licensing and intellectual property is less direct but still significant:

- Potential for increased scrutiny of data transfers across borders: Future regulations regarding data sovereignty and cross-border data flows could significantly impact international software companies.

- Need for enhanced data security and compliance measures: Companies must invest heavily in data security and compliance to meet evolving regulatory demands in a globally fragmented market.

- Adapting licensing models to respond to changing regulatory environments: Software companies need to be agile and adapt their licensing models to account for the changing geopolitical landscape and regulatory requirements.

Strategic Responses and Mitigation Strategies

To successfully navigate tariff turbulence, tech companies are adopting several key strategies:

Reshoring and Nearshoring

Relocating manufacturing facilities closer to primary markets is becoming increasingly attractive:

- Analysis of cost-benefit ratio of reshoring vs. offshoring: Companies carefully weigh the costs and benefits of bringing manufacturing back to their home countries or moving it to nearby regions.

- Government incentives and support for reshoring initiatives: Many governments offer incentives to encourage companies to reshore manufacturing, such as tax breaks and subsidies.

- Challenges of finding skilled labor and establishing new production facilities: However, reshoring faces challenges such as finding skilled labor and building new facilities.

Diversification of Supply Chains

Reducing reliance on single suppliers and geographical locations is paramount:

- Identifying and vetting alternative suppliers: Companies are actively searching for alternative suppliers to diversify their supply chains and reduce risk.

- Investing in supplier relationship management (SRM) systems: Effective SRM systems can help improve supplier collaboration and communication to mitigate supply chain disruptions.

- Building stronger relationships with key suppliers: Stronger supplier relationships improve collaboration and resilience to disruptions.

Lobbying and Advocacy

Engaging directly with policymakers is essential:

- Collaboration with industry associations to present a unified front: Industry associations play a critical role in lobbying efforts, providing a unified voice to policymakers.

- Participation in public consultations and policy discussions: Active participation in policy discussions ensures industry concerns are heard and considered.

- Strategic use of legal channels to challenge unfavorable tariffs: Companies may utilize legal avenues to challenge tariffs deemed unfair or unjustified.

Conclusion

Navigating tariff turbulence requires a proactive and multi-faceted approach. ABI Research's analysis highlights the significant impact of trade wars on the tech sector, necessitating strategic adaptations in manufacturing, supply chain management, and policy engagement. By understanding the challenges and implementing effective mitigation strategies, technology companies can better navigate the complexities of tariff fluctuations and secure their long-term competitiveness. Don’t get caught unprepared – proactively assess your exposure to future tariff turbulence and develop a robust response plan to mitigate the impact of trade wars and tariff increases.

Featured Posts

-

Bce Inc Dividend Cut Reasons And Investor Implications

May 13, 2025

Bce Inc Dividend Cut Reasons And Investor Implications

May 13, 2025 -

Tucows Announces Board Changes New Nominations And Departures

May 13, 2025

Tucows Announces Board Changes New Nominations And Departures

May 13, 2025 -

Fords Shrinking Presence In Brazil Opens Door For Byds Ev Dominance

May 13, 2025

Fords Shrinking Presence In Brazil Opens Door For Byds Ev Dominance

May 13, 2025 -

Erneuter Einsatz An Schule Entwarnung Nach Bombendrohung In Braunschweig

May 13, 2025

Erneuter Einsatz An Schule Entwarnung Nach Bombendrohung In Braunschweig

May 13, 2025 -

Jannes Horn Von Eintracht Braunschweig Zum Rivalen Hannover 96

May 13, 2025

Jannes Horn Von Eintracht Braunschweig Zum Rivalen Hannover 96

May 13, 2025