Navigating The Difficulties Of All-American Production

Table of Contents

Higher Production Costs

One of the most significant obstacles to All-American Production is the inherently higher cost structure compared to manufacturing in many other countries. This increased cost stems primarily from labor expenses and the sourcing of raw materials.

Labor Costs

American labor, while highly skilled and productive, commands significantly higher wages than in many other parts of the world. This directly impacts the final cost of goods.

- Increased labor costs necessitate higher pricing or reduced profit margins. Companies must carefully analyze their pricing strategies to remain competitive.

- Automation and technological advancements can help mitigate, but not eliminate, this issue. Investing in automation can increase efficiency and reduce reliance on high-cost manual labor. However, initial investment costs can be substantial.

- Careful consideration of labor-intensive vs. automated processes is crucial. A thorough cost-benefit analysis is necessary to determine the optimal balance between automation and manual labor. This requires a deep understanding of production processes and technological capabilities.

Raw Material Sourcing

Securing domestically sourced raw materials presents another layer of cost challenges for All-American Production. Finding reliable suppliers within the US, particularly for specialized or rare materials, can be difficult and expensive. Transportation costs within the vast US market also add to the overall expense.

- Reliance on domestic suppliers can lead to supply chain vulnerabilities. Disruptions to domestic supply chains can significantly impact production. Diversification of suppliers is crucial.

- Exploring alternative, sustainable sourcing options within the US is essential. This includes investigating environmentally friendly and ethically sourced materials from within the country. This can also enhance the brand image and appeal to environmentally conscious consumers.

- Potential for higher raw material prices compared to global markets. Domestic raw materials may command higher prices due to factors such as limited supply, increased demand, or transportation costs.

Competition from Foreign Manufacturers

Businesses committed to All-American Production frequently face stiff competition from foreign manufacturers, particularly those in countries with significantly lower labor and production costs. This competition extends beyond simple price wars, encompassing trade policies and market positioning.

Price Competition

The lower production costs enjoyed by many foreign manufacturers often translate into lower prices for consumers. This price competitiveness poses a significant challenge to All-American businesses.

- Developing a strong brand identity and highlighting the "Made in America" value proposition is critical. Emphasizing the quality, durability, and ethical sourcing associated with American-made goods can justify a higher price point.

- Focusing on niche markets or specialized products can help offset price disadvantages. Catering to specific customer needs or preferences reduces direct price competition with mass-produced, lower-cost imports.

- Emphasizing quality, craftsmanship, and sustainability as differentiators. Highlighting the superior quality and craftsmanship of American-made goods can attract customers willing to pay a premium.

Trade Policies and Tariffs

International trade policies and tariffs significantly influence the landscape of All-American Production. These policies can impact the cost of imported raw materials, as well as the competitiveness of domestically produced goods in global markets.

- Staying updated on changes in trade regulations is crucial. Companies must monitor and adapt to evolving trade policies to minimize disruptions.

- Exploring government support programs and incentives for domestic manufacturing. Several government programs provide financial assistance and tax breaks to encourage domestic manufacturing.

- Understanding the implications of tariffs on both input costs and export potential. Tariffs can increase the cost of imported raw materials, while also impacting the price competitiveness of exports.

Finding and Retaining Skilled Labor

Securing and retaining a skilled workforce is another significant challenge for All-American Production. Skills gaps in specific industries and geographic limitations in the availability of talent can hinder growth and efficiency.

Skills Gaps

A shortage of skilled labor in certain sectors creates a bottleneck for expanding All-American production.

- Investing in employee training and development programs. Providing ongoing training and development opportunities helps upskill existing employees and enhances their productivity.

- Partnerships with vocational schools and universities to cultivate a skilled workforce. Collaborating with educational institutions ensures a pipeline of skilled workers for the future.

- Attracting and retaining talent through competitive compensation and benefits packages. Offering competitive salaries and benefits is essential to attract and retain top talent in a competitive job market.

Geographic Limitations

The concentration of skilled labor is not uniform across the US. This geographical disparity can necessitate relocation of facilities or the adoption of remote work strategies.

- Consideration of location advantages and disadvantages in terms of labor pools. Companies must carefully weigh the pros and cons of different locations based on the availability of skilled labor.

- Exploring opportunities in areas with a strong manufacturing heritage. Regions with a history of manufacturing may offer a more readily available and experienced workforce.

- Strategic partnerships with regional economic development agencies. Collaboration with local agencies can provide access to resources and support for attracting and retaining talent.

Conclusion

Successfully navigating the difficulties of All-American Production requires a multifaceted approach. Understanding the higher costs associated with domestic labor and raw materials, while mitigating the competitive pressures from foreign manufacturers, is crucial. Furthermore, businesses must proactively address skills gaps and potential geographic limitations to build a sustainable and competitive All-American production model. By strategically addressing these challenges, companies can reap the rewards of job creation, enhanced national security, and the prestige associated with the "Made in America" label. Start planning your strategy for successful All-American Production today!

Featured Posts

-

Revealed Xs Post Debt Sale Financials And Company Restructuring

Apr 29, 2025

Revealed Xs Post Debt Sale Financials And Company Restructuring

Apr 29, 2025 -

February 20 2025 How To Have A Happy Day

Apr 29, 2025

February 20 2025 How To Have A Happy Day

Apr 29, 2025 -

Post Election Trump Predictions For The Next 100 Days On Trade Regulation And Executive Orders

Apr 29, 2025

Post Election Trump Predictions For The Next 100 Days On Trade Regulation And Executive Orders

Apr 29, 2025 -

Annie Nelson Rebuts Media Misinformation About Willie Nelson

Apr 29, 2025

Annie Nelson Rebuts Media Misinformation About Willie Nelson

Apr 29, 2025 -

Where To Invest Mapping The Countrys Fastest Growing Business Areas

Apr 29, 2025

Where To Invest Mapping The Countrys Fastest Growing Business Areas

Apr 29, 2025

Latest Posts

-

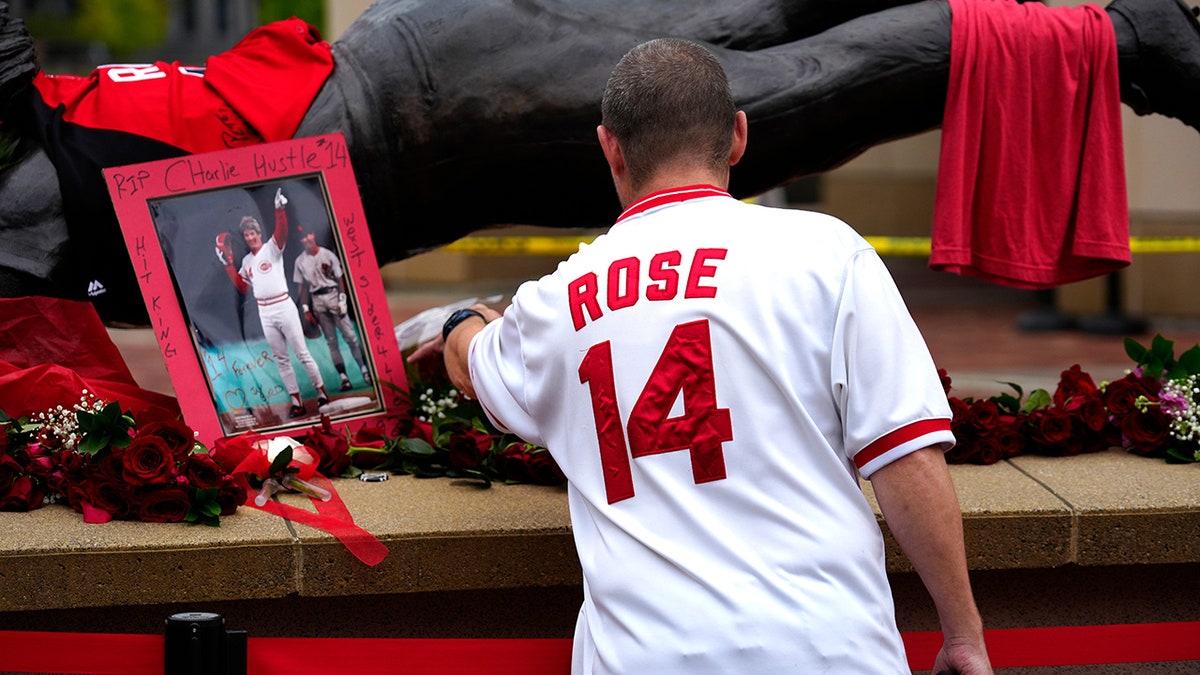

Trump To Pardon Pete Rose After His Death Examining The Announcement

Apr 29, 2025

Trump To Pardon Pete Rose After His Death Examining The Announcement

Apr 29, 2025 -

Will Pete Rose Receive A Posthumous Pardon From Trump Analysis And Reactions

Apr 29, 2025

Will Pete Rose Receive A Posthumous Pardon From Trump Analysis And Reactions

Apr 29, 2025 -

Pete Rose Pardon Trumps Post Presidency Plans

Apr 29, 2025

Pete Rose Pardon Trumps Post Presidency Plans

Apr 29, 2025 -

Johnny Damon And Donald Trump Agree Pete Rose Should Be In Baseball Hall Of Fame

Apr 29, 2025

Johnny Damon And Donald Trump Agree Pete Rose Should Be In Baseball Hall Of Fame

Apr 29, 2025 -

Snow Fox February 11th Check For Delays And Closings Before You Travel

Apr 29, 2025

Snow Fox February 11th Check For Delays And Closings Before You Travel

Apr 29, 2025