The Complexities Of Robotic Nike Sneaker Manufacturing

Table of Contents

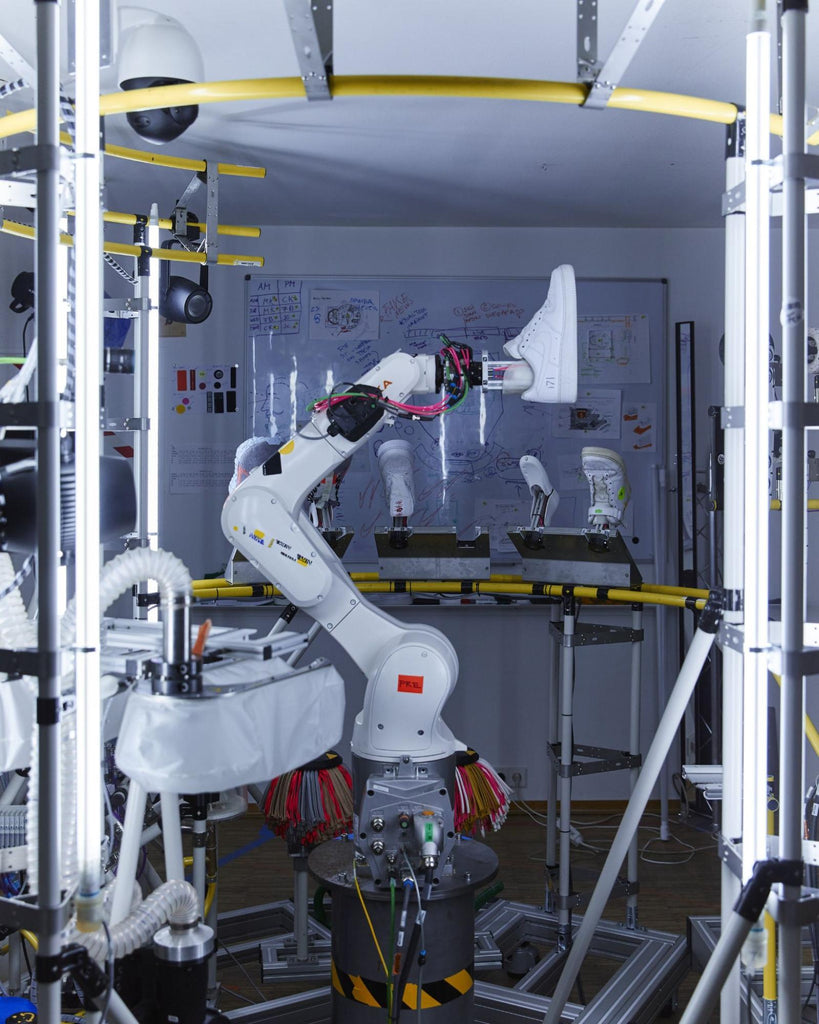

<p>The world of sneaker manufacturing is undergoing a dramatic transformation, driven by the increasing adoption of robotics and automation. Nike, a global leader in athletic footwear, is at the forefront of this revolution, employing sophisticated robotic systems in its factories. However, the integration of robotics into sneaker production presents significant complexities. This article delves into the challenges and opportunities surrounding robotic Nike sneaker manufacturing, exploring the advantages, drawbacks, and future trends of this innovative approach to shoe production.</p>

<h2>The Advantages of Robotic Nike Sneaker Manufacturing</h2>

<h3>Increased Efficiency and Productivity</h3> <p>Robotic systems significantly enhance efficiency and productivity in Nike's sneaker manufacturing process. Automated processes dramatically reduce production time compared to traditional manual methods. This translates to a higher output of sneakers per unit of time, boosting overall production capacity. Furthermore, the precision of robotic systems minimizes errors, leading to improved consistency in product quality. The potential for 24/7 operation with minimal downtime further contributes to increased productivity.</p> <ul> <li>Reduced production time through automated processes.</li> <li>Higher output compared to traditional manual labor.</li> <li>Minimized errors and improved consistency in product quality.</li> <li>Potential for 24/7 operation with minimal downtime.</li> </ul>

<h3>Enhanced Precision and Quality Control</h3> <p>One of the key benefits of robotic Nike sneaker manufacturing is the enhanced precision and quality control it offers. Robots possess superior accuracy in assembly, significantly reducing defects compared to manual assembly lines. Automated quality checks throughout the process ensure higher standards of consistency, leading to fewer imperfections and a higher-quality finished product. This precision extends to the application of adhesives and other materials, contributing to a more durable and aesthetically pleasing final product.</p> <ul> <li>Robots deliver superior accuracy in assembly, reducing defects.</li> <li>Automated quality checks ensure higher standards of consistency.</li> <li>Improved precision in applying adhesives and other materials.</li> <li>Minimized human error leading to higher quality finished products.</li> </ul>

<h3>Cost Savings in the Long Run</h3> <p>While the initial investment in robotic systems is substantial, robotic Nike sneaker manufacturing offers significant cost savings in the long run. Reduced labor costs over time are a major factor. Improved efficiency leads to lower material waste, as robots can precisely utilize resources. Fewer defects mean lower costs associated with repairs or replacements. The cumulative effect of these factors contributes to increased overall profitability through optimized production processes and reduced operational expenses. The long-term return on investment (ROI) is a key driver for Nike's adoption of automated shoe manufacturing.</p> <ul> <li>Reduced labor costs over time.</li> <li>Improved efficiency leads to lower material waste.</li> <li>Fewer defects mean lower costs associated with repairs or replacements.</li> <li>Increased overall profitability through optimized production processes.</li> </ul>

<h2>Challenges in Implementing Robotic Nike Sneaker Manufacturing</h2>

<h3>High Initial Investment Costs</h3> <p>A major hurdle in implementing robotic Nike sneaker manufacturing is the high initial investment cost. The purchase and installation of sophisticated robotic systems and the necessary infrastructure represent a significant upfront expense. Furthermore, there are ongoing costs associated with training personnel to operate and maintain this specialized equipment. Potential for unexpected technical issues and associated repair expenses adds another layer of complexity to the financial considerations.</p> <ul> <li>Significant upfront investment in robotic systems and infrastructure.</li> <li>Costs associated with training and maintenance of robotic equipment.</li> <li>Potential for unexpected technical issues and repair expenses.</li> </ul>

<h3>Integration and Programming Complexity</h3> <p>The intricate nature of sneaker manufacturing poses significant challenges in terms of integration and programming. Developing the software to control the robots and ensure seamless operation requires highly specialized expertise. Integrating these robotic systems with existing production lines can also be complex, requiring careful planning and coordination. The need for specialized expertise in design, implementation, and maintenance adds to the overall complexity.</p> <ul> <li>The intricate nature of sneaker manufacturing requires complex programming.</li> <li>Seamless integration with existing production lines can be challenging.</li> <li>Specialized expertise is necessary for design, implementation, and maintenance.</li> </ul>

<h3>Adaptability and Flexibility Issues</h3> <p>One of the limitations of current robotic systems is their adaptability and flexibility. Robots may struggle to adapt quickly to different sneaker designs and models. This inflexibility in production lines is a significant constraint compared to the adaptability of human workers. Reprogramming robots for new designs can be time-consuming and costly, making it challenging to respond rapidly to changing market demands. This lack of flexibility is a key challenge in the field of automated shoe manufacturing.</p> <ul> <li>Robots may struggle with adapting to different sneaker designs and models.</li> <li>Flexibility in production lines is limited compared to manual labor.</li> <li>Reprogramming robots for new designs can be time-consuming and costly.</li> </ul>

<h3>Job Displacement Concerns</h3> <p>The increased adoption of automation in sneaker manufacturing raises concerns about job displacement for human workers. While automation increases efficiency, it also reduces the need for manual labor in factories. Addressing this challenge requires a proactive approach, including the implementation of retraining and upskilling programs for displaced workers. Ethical considerations surrounding the impact of automation on employment are crucial and require careful consideration by both Nike and the wider industry. The future of work in automated shoe manufacturing necessitates a balanced approach to innovation and worker well-being.</p> <ul> <li>Automation could lead to job losses for human workers in factories.</li> <li>The need for retraining and upskilling programs for displaced workers.</li> <li>Ethical considerations surrounding the impact of automation on employment.</li> </ul>

<h2>The Future of Robotic Nike Sneaker Manufacturing</h2>

<h3>Advancements in AI and Machine Learning</h3> <p>Advancements in artificial intelligence (AI) and machine learning are poised to revolutionize robotic Nike sneaker manufacturing. AI-powered robots can adapt more quickly to changing production demands and learn from experience, improving their performance and efficiency over time. Machine learning algorithms can also optimize maintenance schedules through predictive maintenance, reducing downtime and maximizing uptime. These technological advances will play a key role in improving the efficiency and adaptability of automated shoe production.</p> <ul> <li>AI-powered robots can adapt more quickly to changing production demands.</li> <li>Machine learning improves robot performance and efficiency over time.</li> <li>Predictive maintenance reduces downtime and optimizes maintenance schedules.</li> </ul>

<h3>Collaboration Between Humans and Robots (Cobots)</h3> <p>The future of robotic Nike sneaker manufacturing likely lies in collaborative robots, or cobots. Cobots combine the strengths of both human workers and robots, leveraging human dexterity and problem-solving skills alongside the precision and endurance of robotic systems. Humans can handle complex tasks requiring adaptability and creativity, while robots perform repetitive actions requiring precision and speed. This collaborative approach enhances efficiency and productivity while mitigating the risk of job displacement.</p> <ul> <li>Human-robot collaboration can combine the strengths of both.</li> <li>Humans can handle complex tasks while robots perform repetitive actions.</li> <li>Increased efficiency and productivity with reduced risk of job displacement.</li> </ul>

<h3>Sustainable Manufacturing Practices</h3> <p>Robotic automation has the potential to significantly contribute to more sustainable manufacturing practices in the footwear industry. Reduced material waste, resulting from the precision of robotic systems, is a key benefit. Furthermore, robots can optimize energy consumption and reduce the overall environmental impact of production. Improved sustainability, through precise material handling and reduced errors, aligns with Nike's commitment to environmentally friendly operations. The integration of sustainability into automated shoe manufacturing is a growing trend.</p> <ul> <li>Robotic automation can contribute to environmentally friendly production.</li> <li>Reduced material waste and energy consumption.</li> <li>Improved sustainability through precise material handling and reduced errors.</li> </ul>

<h2>Conclusion</h2>

<p>Robotic Nike sneaker manufacturing presents a complex interplay of advantages and challenges. While high initial investment costs and integration complexities are undeniable hurdles, the potential for increased efficiency, improved quality, and long-term cost savings are significant drivers of adoption. The future likely lies in collaborative robotics and advanced AI, enabling a more sustainable and efficient production process. Understanding these complexities is crucial for Nike and the broader footwear industry as they navigate the evolving landscape of automated shoe production. To stay informed about the latest innovations in robotic Nike sneaker manufacturing, keep exploring this fascinating field and researching advancements in AI and cobot technologies within the context of automated shoe production. The future of sneaker manufacturing is being shaped by these exciting developments.</p>

Featured Posts

-

Mapping The Countrys Emerging Business Hubs

Apr 22, 2025

Mapping The Countrys Emerging Business Hubs

Apr 22, 2025 -

Stock Market Today Dow Futures Fall Dollar Weakens Amid Trade Tensions

Apr 22, 2025

Stock Market Today Dow Futures Fall Dollar Weakens Amid Trade Tensions

Apr 22, 2025 -

Trade War Concerns Weigh On Markets Dow Futures Dollar Dip Live Updates

Apr 22, 2025

Trade War Concerns Weigh On Markets Dow Futures Dollar Dip Live Updates

Apr 22, 2025 -

Metas Future Under The Shadow Of The Trump Administration

Apr 22, 2025

Metas Future Under The Shadow Of The Trump Administration

Apr 22, 2025 -

The Future Of Luxury Cars In China Perspectives From Bmw And Porsches Experiences

Apr 22, 2025

The Future Of Luxury Cars In China Perspectives From Bmw And Porsches Experiences

Apr 22, 2025