U.S. Companies Slash Costs Amid Tariff Uncertainty

Table of Contents

Shifting Supply Chains to Mitigate Tariff Impacts

Tariff mitigation strategies are at the forefront of many companies' responses. The uncertainty surrounding tariffs necessitates a dynamic approach to supply chain management. Companies are actively pursuing supply chain diversification, employing both offshoring and nearshoring strategies to reduce their reliance on regions subject to high tariffs.

-

Offshoring: Relocating manufacturing to countries with more favorable trade agreements, such as Vietnam or Bangladesh, offers cost savings but presents challenges including increased transportation costs and longer lead times. For example, several apparel companies have shifted production from China to Vietnam to avoid escalating tariffs.

-

Nearshoring: Moving production to nearby countries, like Mexico or Canada, reduces shipping distances and logistical complexities. However, labor costs in these regions may be higher than in distant offshoring locations. Many automotive parts manufacturers are exploring nearshoring opportunities in Mexico.

-

Challenges: The transition to new supply chains is costly and complex, requiring significant investment in infrastructure, logistics, and workforce training. Moreover, navigating differing regulations and standards in new markets presents additional hurdles.

Embracing Automation and Technological Advancements

In response to tariff-related cost pressures, many U.S. companies are accelerating their automation investments. Robotics, AI, and other advanced technologies are seen as crucial tools for enhancing efficiency and reducing labor costs. This shift towards automation is not limited to manufacturing; agricultural businesses are also adopting robotic solutions to optimize efficiency and cut expenses.

-

Return on Investment (ROI): While the initial investment in automation can be significant, the long-term ROI can be substantial, leading to reduced labor costs, improved product quality, and increased productivity.

-

Examples: The manufacturing sector is witnessing widespread adoption of robotic process automation (RPA), while AI-powered systems are being integrated in various industries to optimize supply chain management and predict market trends.

-

Employment Impact: While automation may lead to job displacement in some sectors, it also creates new opportunities in areas such as robotics engineering, AI development, and data analytics.

Workforce Adjustments and Cost Optimization Strategies

To manage escalating costs, U.S. businesses are implementing various workforce adjustments. These include everything from wage freezes and hiring freezes to more drastic measures such as layoffs and restructuring. Other cost-cutting measures extend beyond the workforce, including:

-

Wage Freezes/Reductions: Many companies are implementing wage freezes or implementing modest wage increases to contain labor costs.

-

Hiring Freezes: To curtail expenses, companies are reducing or eliminating new hires, impacting future growth potential.

-

Layoffs & Restructuring: In some cases, companies have resorted to layoffs and organizational restructuring to reduce their overall workforce.

-

Other Cost-Cutting Measures: Besides workforce adjustments, cost-cutting measures also include negotiating better deals with suppliers, reducing marketing budgets, and optimizing operational efficiencies.

The Impact of Tariff Uncertainty on Business Investment

Tariff uncertainty significantly impacts business investment and long-term economic growth. The unpredictable nature of tariffs creates hesitancy among businesses, leading to a decline in capital expenditures. Companies are delaying or canceling projects, hindering innovation and long-term planning.

-

Reduced Capital Expenditures: Uncertainty makes it difficult for businesses to make informed investment decisions, leading to a decrease in capital expenditures.

-

Postponed Projects: Many companies are postponing expansion plans, technology upgrades, and research and development initiatives due to tariff uncertainty.

-

Economic Slowdown: The overall reduction in business investment contributes to a broader economic slowdown, affecting job creation and overall economic growth.

Navigating the Challenges of U.S. Companies and Tariff Uncertainty

In conclusion, U.S. companies are responding to tariff uncertainty by employing a range of cost-cutting strategies, including shifting supply chains, embracing automation, adjusting their workforce, and delaying investments. The implications are far-reaching, affecting employment, economic growth, and the overall business landscape. Understanding these challenges and developing effective cost-reduction strategies is crucial for navigating the complexities of the global trade environment. To learn more about navigating tariff uncertainty and implementing effective cost-cutting strategies, explore resources on international trade and economic forecasting. Staying informed on the latest developments in U.S. companies slashing costs amid tariff uncertainty is crucial for businesses to thrive in this dynamic environment.

Featured Posts

-

Dlyl Shaml Lmerd Fn Abwzby 2024

Apr 29, 2025

Dlyl Shaml Lmerd Fn Abwzby 2024

Apr 29, 2025 -

Reliance Industries Earnings Impact On Indian Large Cap Market Performance

Apr 29, 2025

Reliance Industries Earnings Impact On Indian Large Cap Market Performance

Apr 29, 2025 -

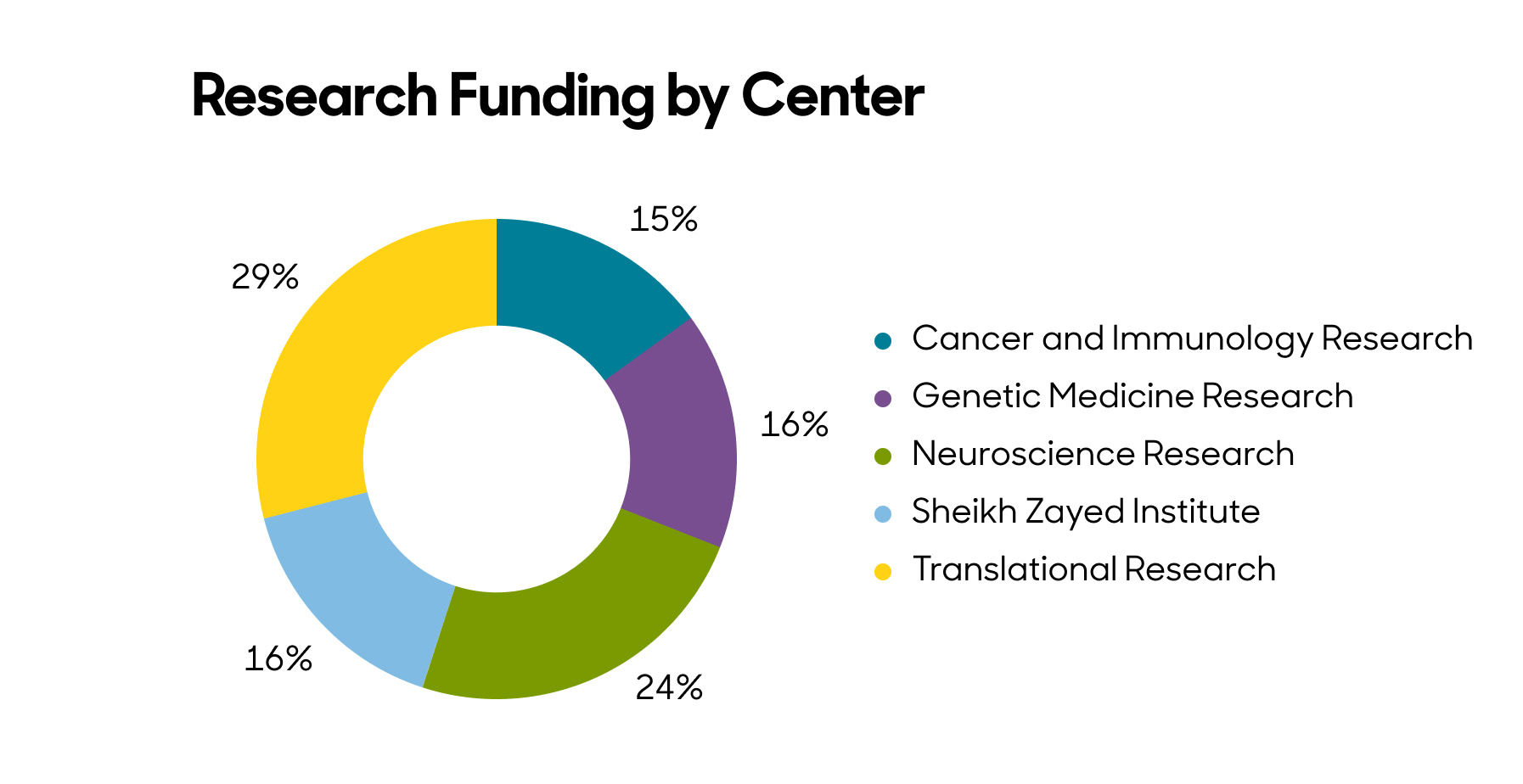

Us Research Funding Cuts Spark International Talent Grab

Apr 29, 2025

Us Research Funding Cuts Spark International Talent Grab

Apr 29, 2025 -

2 5 Trillion Vanished The Stunning Losses Of The Magnificent Seven Stocks

Apr 29, 2025

2 5 Trillion Vanished The Stunning Losses Of The Magnificent Seven Stocks

Apr 29, 2025 -

Cassidy Hutchinson To Publish Memoir On January 6th Hearings

Apr 29, 2025

Cassidy Hutchinson To Publish Memoir On January 6th Hearings

Apr 29, 2025

Latest Posts

-

Understanding Russias Military Strategy And Its Impact On Europe

Apr 29, 2025

Understanding Russias Military Strategy And Its Impact On Europe

Apr 29, 2025 -

International Condemnation Of Israeli Aid Ban As Gaza Suffers

Apr 29, 2025

International Condemnation Of Israeli Aid Ban As Gaza Suffers

Apr 29, 2025 -

Humanitarian Crisis In Gaza Demand For Israel To Lift Aid Restrictions

Apr 29, 2025

Humanitarian Crisis In Gaza Demand For Israel To Lift Aid Restrictions

Apr 29, 2025 -

Can Perplexitys Ai Beat Google A Conversation With The Ceo

Apr 29, 2025

Can Perplexitys Ai Beat Google A Conversation With The Ceo

Apr 29, 2025 -

Criminal Charges Lab Owner Convicted Of Fraudulent Covid Testing

Apr 29, 2025

Criminal Charges Lab Owner Convicted Of Fraudulent Covid Testing

Apr 29, 2025